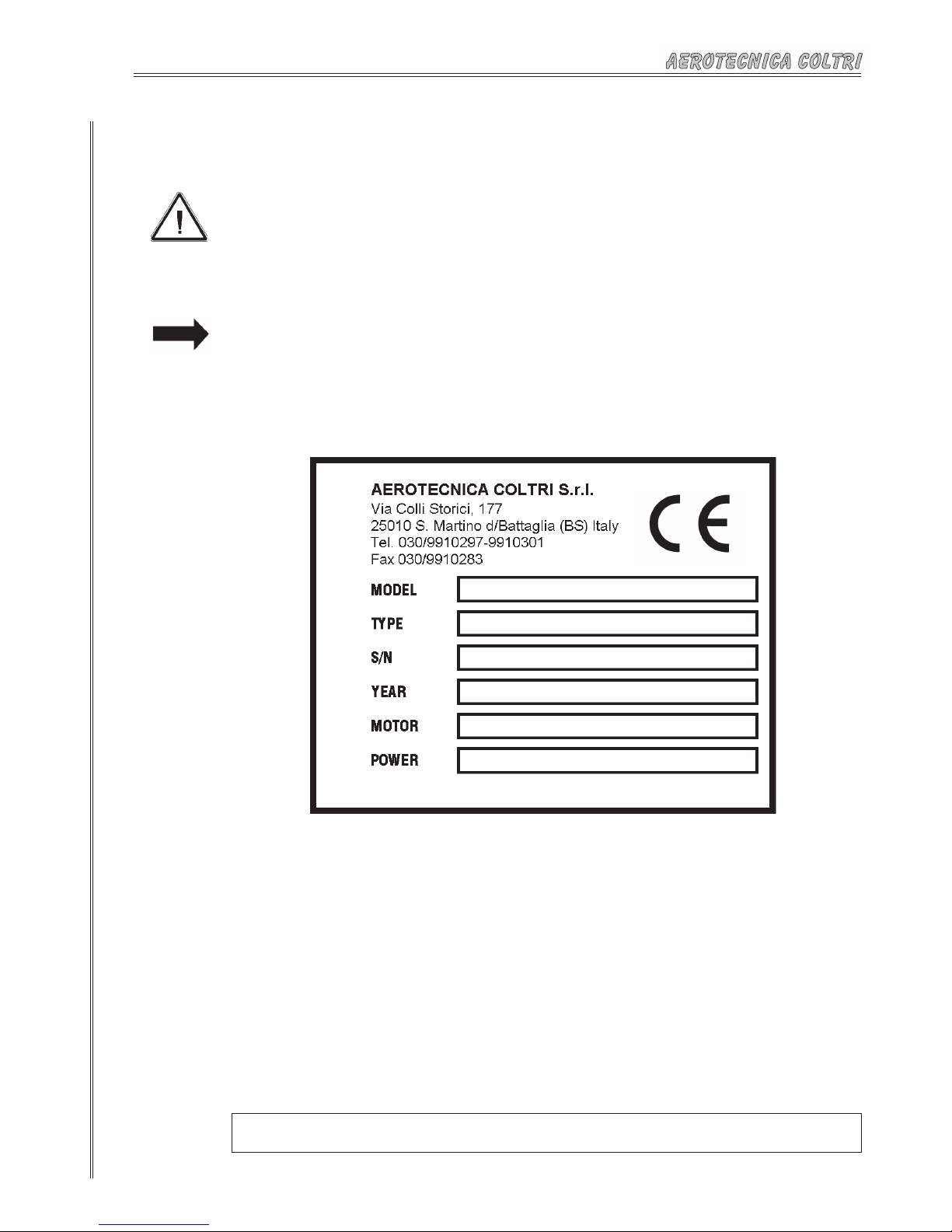

11

This system supplies a breathable gas stream consisting of an elevated oxygen content relative to

normalatmosphericcontent ofapproximately21%O2byvolume. Thistechnique employsgasseparation

technologyutilizingapermeablemembraneto separatecertaingas moleculesfromother gasmolecules

allowinga controlledflow ofoutput gassesof differingoxygen concentrations.

Thissystem producesDNAx Nitroxin oxygenconcentrations of22% to40% atmaximum pressuresof

3200- 3700PSI. A supplygas, inthis case,“Grade-E”air,will berequired. Thissupply gasis fedatlow

pressure(145-185 PSI)to theinput portof themembrane. Thegasstreamis fedthrough athermostat-

controlled heater. As the gas moves through this assembly, its temperature is raised to

35° (110 degrees F). The purpose of this heater is to even out the variations in gas temperature and

produce a more linear performance curve. Once through the heater, the input gas is allowed to pass

through the membrane. As the gas passes through the membrane, the gas volume applies pressure

againstthe insidewallsof thepermeablefibers resultinginthe migrationacrossthe wallofvarying levels

of the different constituents of air. Gas volumes of desired O2concentrations are achieved in this

manner. In this stage the normal oxygen content of the “Grade-E” air second the norms UNI EN 132,

CGA-Eand DIN 3188(20.9%) israised tooutput percentagesupwardsof 23%to 40%.

A needle valve in the outlet stream of the waste gas (nitrogen) controls the relative O2concentrations

whileinput pressureregulationallows controloftheoutputvolume ofthemembrane. This outletvolume

control is required to balance the input requirements of the high-pressure compressor. As the gas

volume of desired oxygen concentration is produced it is contained and directed to the inlet port of the

high-pressurecompressor. Anoverpressure checkvalveisinstalledin theinletfittingof thehigh-pressure

compressor to protect the compressor from over pressurization of the first stage. Negative pressure

protectionisaccomplishedinthesamemannerby installinganunder-pressurecheckvalvein theambient

air intake side of the membrane output fitting.

As the gas volume is subsequently compressed, it is alternately cooled and raised in pressure again

until it reaches its final design output pressure. Final filtration and purification is accomplished at final

compressordischarge.

Product gas “DNAx” nitrox is available at desired oxygen concentrations (up to 40% O2by volume) at

maximum pressures of 3200 - 3700 PSI, for filling Nitrox Storage Bottles or SCUBA cylinders.

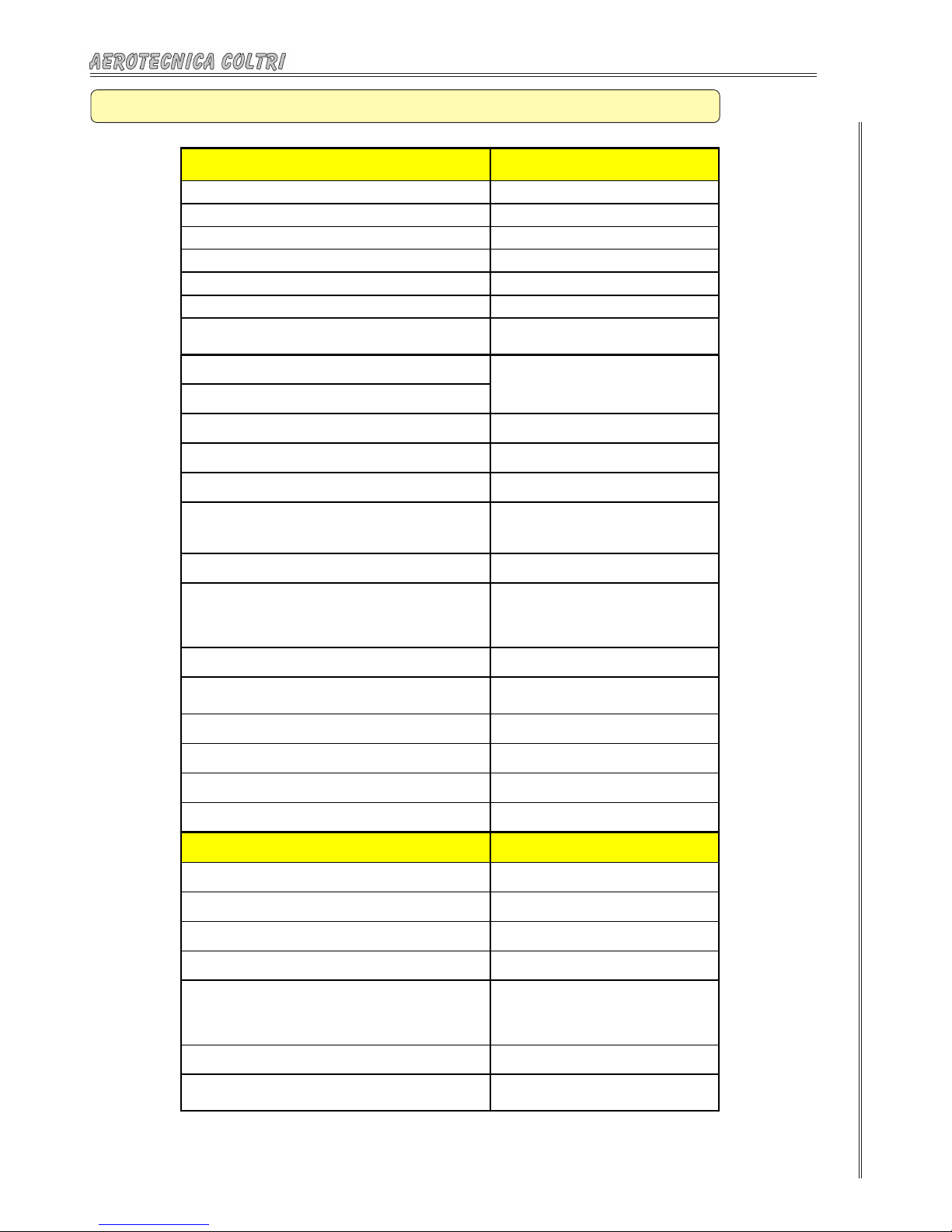

Typical Specification for Air :

O2Percentage: ..................................20-22%

CO2:.................................................1000 PPM

CO: ..................................................10 PPM

Hydrocarbons:..................................25 PPM

Water:..............................................67 PPM

DewPoint: .......................................- 50° F

Oil & Particles:................................. 5mg/m3

Odor:................................................Nessuno

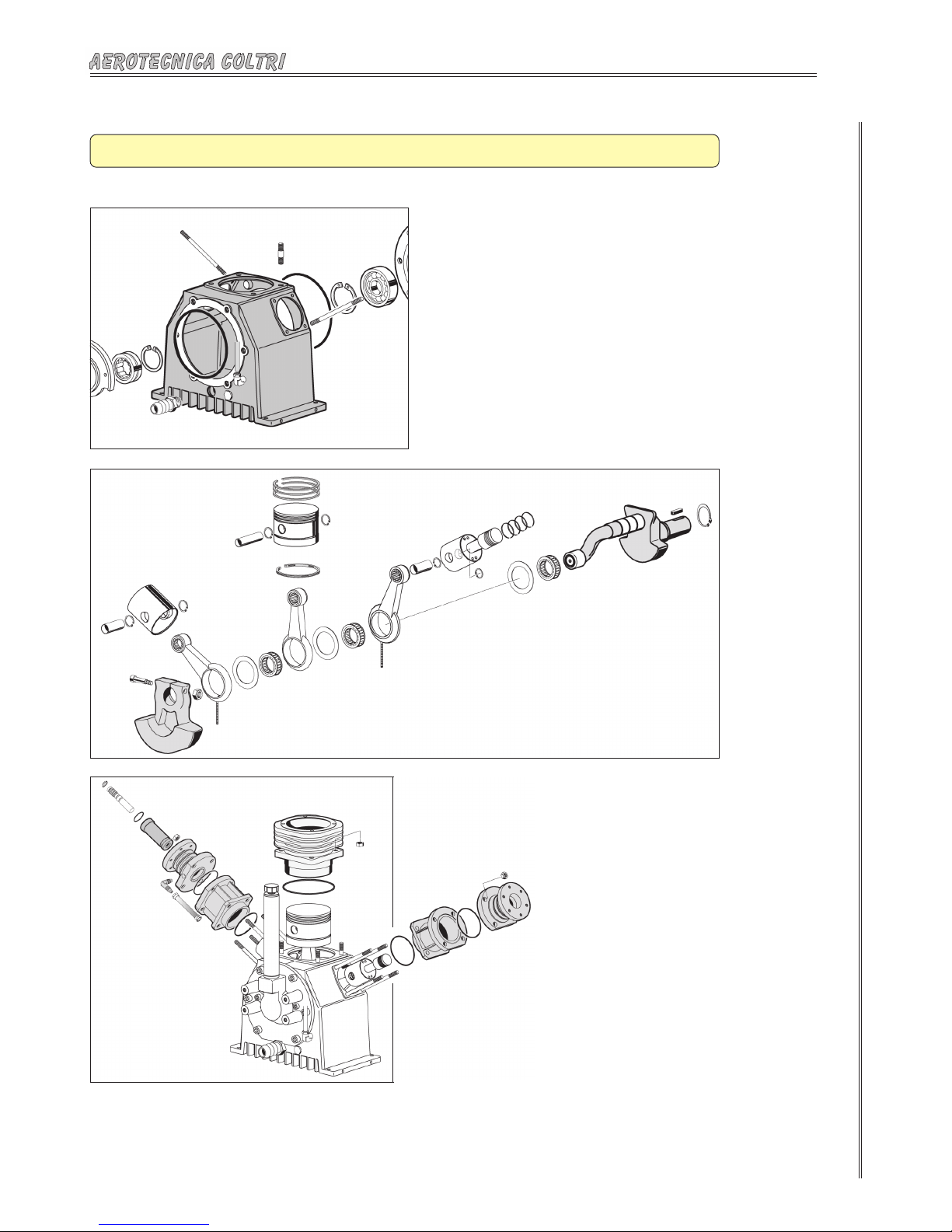

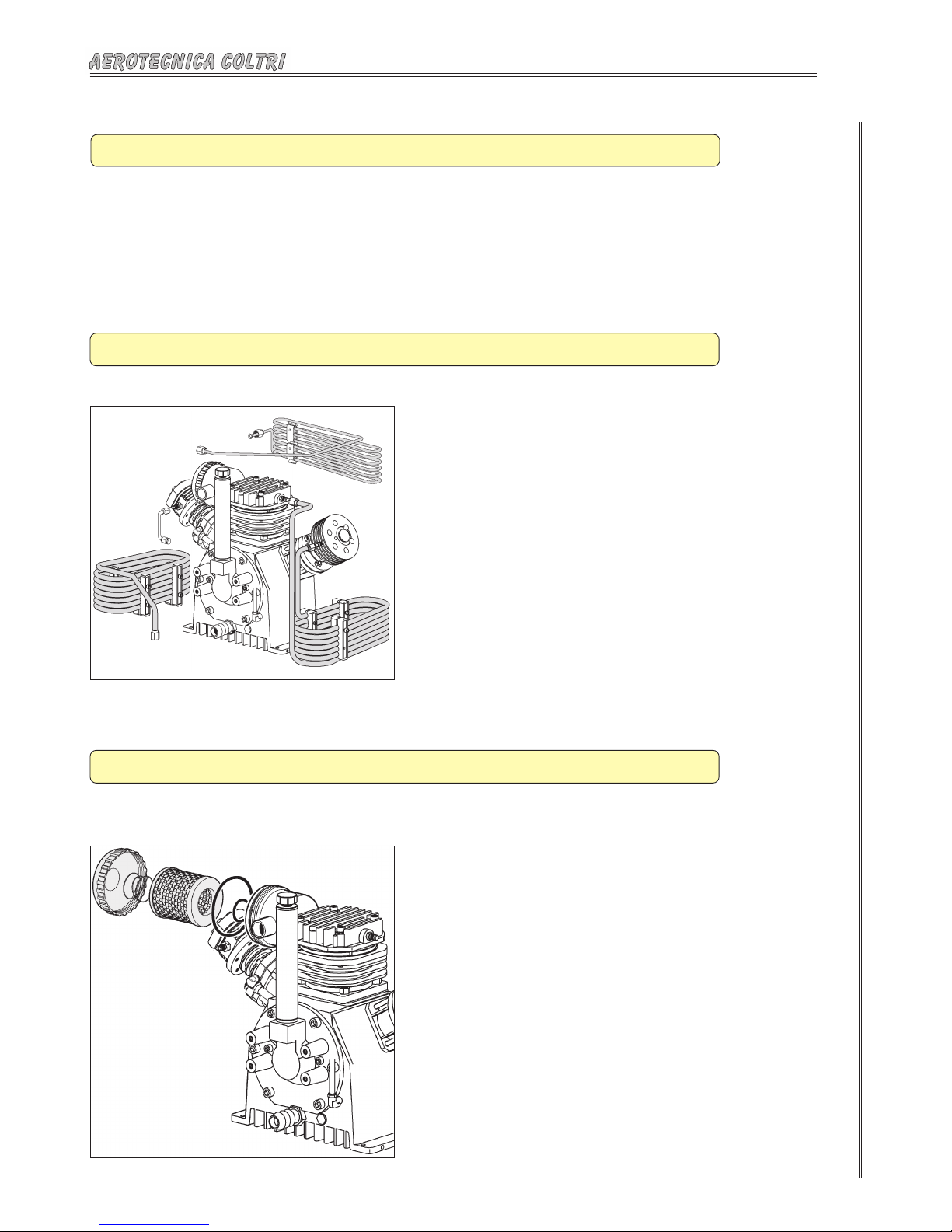

Technical description