GEA Grasso VHS Series User manual

Other GEA Air Compressor manuals

GEA

GEA HGX12P CO2 User manual

GEA

GEA HA4 User manual

GEA

GEA HG5/725-4 User manual

GEA

GEA Bock HGX2 CO2 T Series User manual

GEA

GEA HG34P/e User manual

GEA

GEA Bock HG8 Series User manual

GEA

GEA pluscom Bock EX-HG12P User manual

GEA

GEA HGX46/280-4 ML CO2T User manual

GEA

GEA Bock F76 Series User manual

GEA

GEA HGX34 CO2 T Series User manual

GEA

GEA HGX7 R134a User manual

GEA

GEA HG12P User manual

GEA

GEA F Series User manual

GEA

GEA Grasso RC9 Series User manual

GEA

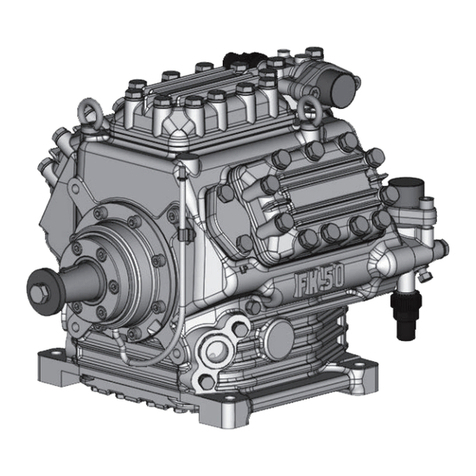

GEA FK50/460 N User manual

GEA

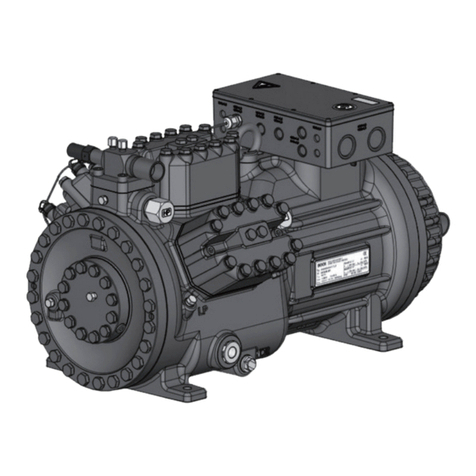

GEA Bock HGX46 CO2 T Series User manual

GEA

GEA GEA Bock HG66e Series User manual

GEA

GEA HGX34/110-4 ML CO2 T User manual

GEA

GEA HA22P/125-4 User manual

GEA

GEA HGX6 R134a series User manual