Aesculap Econom CL User manual

Aesculap

Econom CL

Econom CL Equipe

Econom CL Fitter

Bruksanvisning/Teknisk Beskrivelse

Klippemaskin til storfe og hest

Econom CL (GT800)

Econom CL Set 1 batteri (GT804)/2 batterier (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 batteri (GT814)/2 batterier (GT816)

Econom CL Fitter Set 1 batteri (GT834)

Bruksanvisning/Teknisk Beskrivning

Nötkreaturs- och hästklippmaskin

Econom CL (GT800)

Econom CL Set 1 batteri (GT804)/2 batterier (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 batteri (GT814)/2 batterier (GT816)

Econom CL Fitter Set 1 batteri (GT834)

Käyttöohjeet/Tekninen Kuvaus

Karjan ja hevosen klipperi

Econom CL (GT800)

Econom CL Set 1 akku (GT804)/2 akkuja (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 akku (GT814)/2 akkuja (GT816)

Econom CL Fitter Set 1 akku (GT834)

Инструкция по примению/Техническое описание

Машинка для стрижки крупного рогатого скота и лошадей

Econom CL (GT800)

Econom CL Set 1 аккумулятор (GT804)/2 аккумулятора (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 аккумулятор (GT814)/

2 аккумулятора (GT816)

Econom CL Fitter Set 1 аккумулятор (GT834)

Instrukcja u¿ytkowania/Opis Techniczny

Maszynka do strzy¿enia sierœci bydlêcej i koñskiej

Econom CL (GT800)

Econom CL Set 1 akumulator (GT804)/2 akumulatory (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 akumulator (GT814)/2 akumulatory (GT816)

Econom CL Fitter Set 1 akumulator (GT834)

取扱説明書

動物用バリカン

Econom CL (GT800)

Econom CL Set 1 バッテリー (GT804)/2 つのバッテリー (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 バッテリー (GT814)/2 つのバッテリー (GT816)

Hebräisch

Klippemaskine til kvæg og heste

Econom CL (GT800)

Econom CL Set 1 Akku (GT804)/2 Akkus (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 Akku (GT814)/2 Akkus (GT816)

Econom CL Fitter Set 1 Akku (GT834)

IL

Instructions for use/Technical description

Cattle and horse clipping machine

Econom CL (GT800)

Econom CL Set 1 battery (GT804)/2 batteries (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 battery (GT814)/2 batteries (GT816)

Econom CL Fitter Set 1 battery (GT834)

Gebrauchsanweisung/Technische Beschreibung

Rinder- und Pferdeschermaschine

Econom CL (GT800)

Econom CL Set 1 Akku (GT804)/2 Akkus (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 Akku (GT814)/2 Akkus (GT816)

Econom CL Fitter Set 1 Akku (GT834)

Mode d’emploi/Description technique

Tondeuse pour la tonte des bovins et chevaux

Econom CL (GT800)

Econom CL Set 1 batterie (GT804)/2 batteries (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 batterie (GT814)/2 batteries (GT816)

Econom CL Fitter Set 1 batterie (GT834)

Instrucciones de manejo/Descripción técnica

Máquina para bovinos y caballos

Econom CL (GT800)

Econom CL Set 1 batería (GT804)/2 baterías (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 batería (GT814)/2 baterías (GT816)

Econom CL Fitter Set 1 batería (GT834)

Istruzioni per l’uso/Descrizione tecnica

Tosatrice per bovini ed equini

Econom CL (GT800)

Econom CL Set 1 accumulatore (GT804)/2 accumulatori (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 accumulatore (GT814)/2 accumulatori (GT816)

Econom CL Fitter Set 1 accumulatore (GT834)

Gebruiksaanwijzing/Technische Beschrijving

Tondeuze voor runderen en paarden

Econom CL (GT800)

Econom CL Set 1 accu (GT804)/2 accu’s (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 accu (GT814)/2 accu’s (GT816)

Econom CL Fitter Set 1 accu (GT834)

Brugsanvisning/Teknisk Beskrivelse

Klippemaskine til kvæg og heste

Econom CL (GT800)

Econom CL Set 1 akkumulator (GT804)/2 akkumulatorer (GT806)

Econom CL Equipe (GT810)

Econom CL Equipe Set 1 akkumulator (GT814)/2 akkumulatorer (GT816)

Econom CL Fitter Set 1 akkumulator (GT834)

234

1

36 37/38 39

6

7

c

b

10

78

10

9

11

ed

37/38 39

CDE

FG

BA

a

9

1

2

40

11 8

43

17

17

18

19

20

9

9

2

1

25

6

6

26

16

15

10

7

27

2

Econom CL/Econom CL Equipe/Econom CL Fitter cattle and horse clipping machine

Aesculap®

Overview Symbols on product

Contents

1. Safe handling .................................................................................................. 3

2. Product description ....................................................................................... 3

2.1 Package includes............................................................................................ 3

2.2 Components required for operation ......................................................... 3

2.3 Intended use.................................................................................................... 3

2.4 Operating principle........................................................................................ 4

3. Preparation ...................................................................................................... 4

4. Working with the battery-operated clipping machine, charger

and lithium ion battery................................................................................ 4

4.1 System set-up ................................................................................................. 4

4.2 Function check................................................................................................ 4

4.3 Connecting the charger/Charging the Li-ion battery.......................... 5

4.4 Change the Li-ion battery ........................................................................... 5

4.5 Handling the cutter head ............................................................................ 6

4.6 Storage.............................................................................................................. 7

5. Cutter plates.................................................................................................... 7

5.1 Cutter plates compatible with cutter head GT367 .............................. 7

5.2 Recommended combinations ..................................................................... 7

6. Reprocessing ................................................................................................... 8

6.1 Cleaning/disinfection.................................................................................... 8

6.2 Inspection and checking .............................................................................. 8

7. Maintenance ................................................................................................... 8

8. Troubleshooting.............................................................................................. 9

8.1 Battery-operated clipping machine Econom CL/

Econom CL Equipe/Econom CL Fitter ....................................................... 9

8.2 Charger and Li-ion battery....................................................................... 10

9. Technical Service......................................................................................... 11

10. Accessories/Spare parts............................................................................. 11

11. Technical Data ............................................................................................. 12

11.1 Battery-operated clipping machine Econom CL/

Econom CL Equipe/Econom CL Fitter ......................................................12

11.2 Charger .......................................................................................................... 12

11.3 Li-ion battery ............................................................................................... 12

11.4 Declaration of conformity ........................................................................ 12

12. Disposal.......................................................................................................... 12

12.1 For EU countries only................................................................................. 12

12.2 Li-ion battery ............................................................................................... 12

13. Two year guarantee.................................................................................... 13

Pos. Art. no. Number Name

1GT502 1

Lower cutter plate (GT804–GT816/GT834)

2GT501 1 Upper cutter plate (GT804/GT806/GT834)

GT505 1 Upper cutter plate (GT814/GT816)

3GT610405 1 Knurled nut

4GT367205 1 Adjusting screw

6TA010017 2 Drive pin

7GT367201 1 Oscillator

8GT610304 1 Oscillating block

9GT610010 2 Fixing screw

10 GT367202 6 Oscillating spring leaf

11 GT367812 1 Spur gear with eccentric shaft

15 TA008295 2 Guide pin

16 GT367801 1 Mounted cutter head housing

17 TA005091 2 Drive pin

18 GT367802 1 Left distance part

19 GT367803 1 Right distance part

20 TA007765 1 Countersunk screw

25 GT610307 1 Spring bridge

26 GT367207 1 Fixation screw

27 GT367804 1 Mounted oscillator

35 TA009222 1 Screwdriver

36 GT800249 1 On/off button (with LED)

37 GT800804 1 Airfilter (blue)

Econom CL

38 GT800844 1 Airfilter (bordeaux)

Econom CL Equipe

39 GT801 1 Lithium ion battery

40 GT803 1 Charger

a– 1 Lubricating point for battery-operated

clipping machine

b– 1 Tips of the oscillator

c– 1 Holes in the upper cutter plate

d– 1 Li-ion battery charging status display

e– 1 Li-ion battery button

f– 1 Battery lock

gGT800/

GT810

1IntheUK

– GT604 1 Special lubricating oil for cutter head

and cutter plates

GT605 1 Gear grease (tube)

Caution, general warning symbol

Caution, see documentation supplied with the product

Labeling of electrical and electronic devices according

to directive 2012/19/EU (WEEE), see Disposal

3

1. Safe handling

¾Prior to use, check that the product is in good working order.

¾Store the charger and Li-ion batteries at room temperature.

¾Keep dry the charger and Li-ion batteries.

¾Charge the Li-ion batteries prior to first use.

¾To prevent damage caused by improper setup or operation, and to not

compromise the manufacturer warranty and liability:

– Use the product only according to these instructions for use.

– Follow the safety and maintenance instructions.

– Only combine Aesculap products with each other.

¾Keep the instructions for use accessible for the user.

¾Always adhere to applicable standards.

¾Ensure that the electrical facilities in the room in which the device is

being used conform to IEC norms.

¾Unplug the device by pulling the plug, but never by pulling the power

cord.

¾Do not operate the product in explosion-hazard areas.

¾Do not use the product if it is damaged or defective. Set aside the

product if it is damaged.

2. Product description

2.1 Package includes

2.2 Components required for operation

• Battery-operated clipping machine Econom CL/Econom CL Equipe/

Econom CL Fitter

•Charger

• Mains power cord (with device plug)

• Li-ion battery

2.3 Intended use

Battery-operated clipping machine Econom CL/Econom CL Equipe/

Econom CL Fitter

The battery-operated clipping machine Econom CL/Econom CL Equipe/

Econom CL Fitter is used for clipping large animals such as cattle, horses

and large dogs.

Charger GT803/Li-ion battery GT801

The GT803 charger is used to charge the GT801 lithium ion battery.

DANGER

Risk of death by electric shock!

¾Do not open the product.

¾Connect the product only to a grounded power

supply. Art. no. Designation

GT800

GT810

GT834

Battery-operated clipping machine Econom CL,

Econom CL Equipe or

Econom CL Fitter

GT801 Li-ion battery

GT803 Charger

seeAccessories/Spare

parts

Mains power cord (with device plug)

TA013895 Instructions for use

GT604 Hand oiler

4

Econom CL/Econom CL Equipe/Econom CL Fitter cattle and horse clipping machine

Aesculap®

2.4 Operating principle

Battery-operated clipping machine Econom CL/Econom CL Equipe/

Econom CL Fitter

The battery-operated clipping machine Econom CL/Econom CL Equipe/

Econom CL Fitter is switched on and off using the on/off button 36.

Note

The on/off button only reacts after >0.5 s in order to avoid the machine

being switched on or off unintentionally.

Charger GT803/Li-ion battery GT801

The charger GT803 is designed for a mains voltage/frequency range of

100 V to 240 V and 50 Hz to 60 Hz.

To make the charger GT803 ready for operation, connect it to mains power

by plugging in the mains plug.

The charger GT803 is equipped with one charging bay.

Charging starts automatically as soon as the Li-ion battery is inserted in

the charging station.

The charging time depends on the charge state and capacity of the Li-ion

battery.

Charging principle

The Li-ion batteries are charged by constant current pulses.

The charge state of the Li-ion battery is monitored during charging.

Monitoring of the charging curve ensures that the battery is fully charged

without overcharging.

Additionally, the battery temperature and charging time are monitored as

well.

The charge status display dof the lithium ion battery has 5 LEDs. Each LED

stands for 20 % of charge volume. When the battery is charging, the LED

of the respective charging status blinks. When all the LEDs are

permanently illuminated, the battery is completely charged.

Charging time

Charging is stopped as soon as the maximum charging time is reached. The

charging time is approx. 70 min.

3. Preparation

Non-compliance with the following rules will result in complete exclusion

of liability on the part of Aesculap.

¾Always observe the following guidelines when setting up and

operating the product:

– national regulations for installation and operation,

– the national regulations on fire and explosion protection,

– operating advisories according to IEC-/VDE regulations.

4. Working with the battery-operated

clipping machine, charger and lithium

ion battery

4.1 System set-up

Connecting the accessories

Combinations of accessories that are not mentioned in the present

instructions for use may only be employed if they are specifically intended

for the respective application, and if they do not compromise the

performance and safety characteristics of the products.

4.2 Function check

Battery-operated clipping machine Econom CL/Econom CL Equipe/

Econom CL Fitter

¾Carry out a visual inspection.

¾Ensure that the airfilter 37/38 is positioned correctly, see Fig. G.

¾Push the lithium ion battery 39 into the machine shaft and lock it.

¾Check if the battery is charged-up: Press button e, see Fig. F.

¾The charge status display dindicates the charge status.

Note

In order to prevent the lithium iron battery discharging when the machine

is not being used, the electronic connection between the lithium ion

battery and the control system for the battery-operated clipping machine

is cut after 1 hour.

¾Reactivating the lithium ion battery 39: Press button e, see Fig. F.

All the LEDs in the charge status display dilluminate.

Charger/Li-ion battery

¾Carry out a visual inspection.

¾Prior to connecting the product to mains power:

–Check the mains power cord for any damage.

–Check the product for any damage (e.g. bent contacts of the charging

bay).

¾Plug in mains power cord at the device socket of the charging station.

¾Plug in the mains plug at the mains power socket.

¾Place the lithium lithium iron battery 39 in the charging bay of the

charger and charge it, see Fig. F.

5

4.3 Connecting the charger/Charging the Li-ion battery

Note

The charger can be used by children if 8 years or older, as well as by persons

with reduced physical, sensory or mental capacities or with lack of

experience and knowledge, if these persons are supervised or have been

instructed on how to use the device safely, and if they understand the risks

associated with the use of the device.

¾Do not allow children to play with the device.

¾Do not allow children to clean or maintain the device without

supervision.

Note

The Li-ion battery heats up slightly during charging.

Note

Disconnect the mains power cord at the mains socket when the charger is

not going to be used.

¾Only use the Aesculap GT803 charger for charging the lithium ion

batteries.

¾To connect charger 40: Plug the device plug of the mains power cord

into the charger.

¾Plug in the mains plug of mains power cord at the mains power socket.

¾Plug the lithium iron battery 39 into the charging bay of the charger

and charge it, see Fig. F.

The LEDs in the charge status display dof the lithium ion battery blink

in accordance with the current charge status. When all the LEDs are

permanently illuminated, the battery is completely charged.

4.4 Change the Li-ion battery

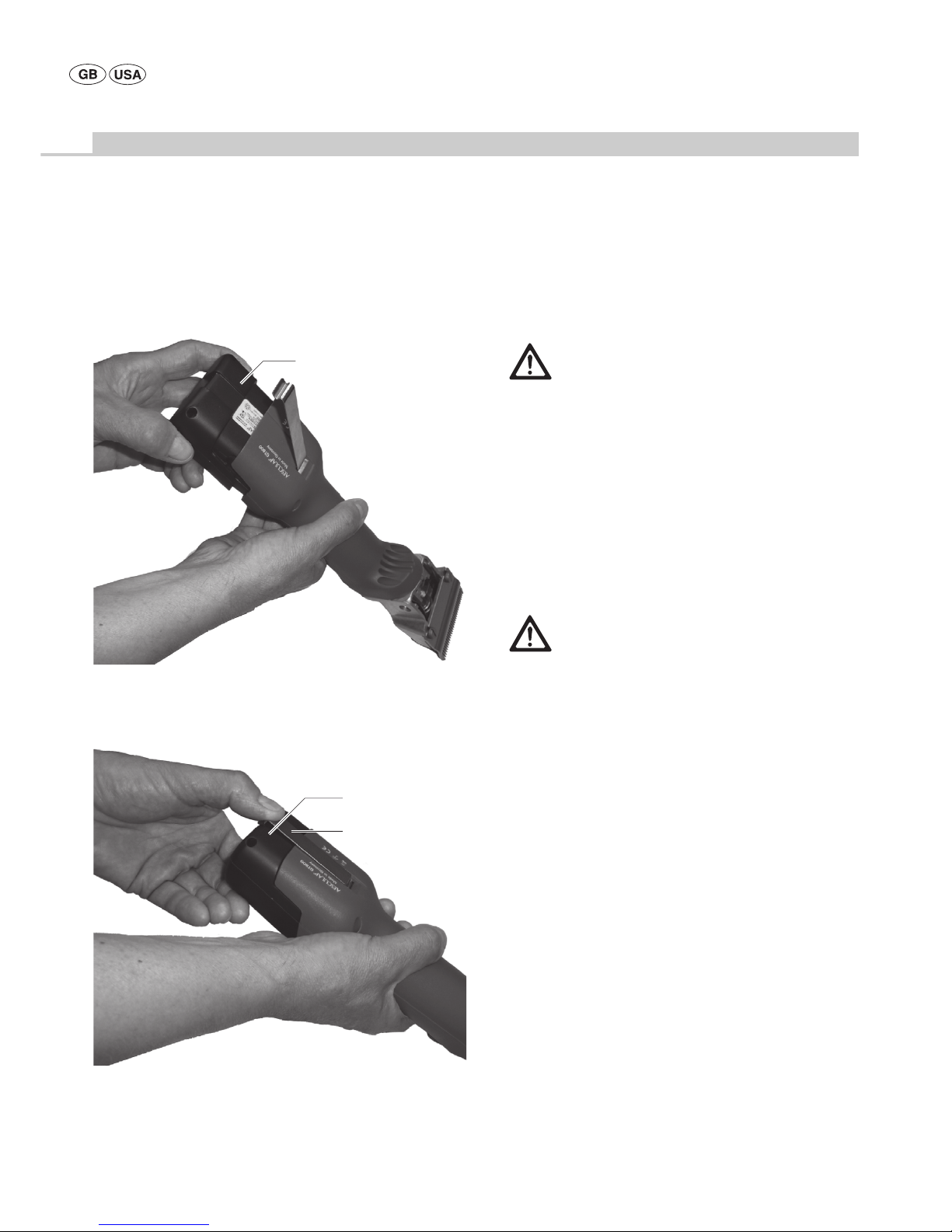

¾Hold the battery-operated clipping machine gwith the cutter head

downwards so that the lithium ion battery 39 does not fall down when

loosened, see Fig. 1.

¾Loosen the battery lock fwith your thumb.

Fig. 1

WARNING

Fire hazard due to battery poles shorted by fluids

or metal components!

¾Li-ion battery not inserted

WARNING

Risk of injury due to damaged mains power cord!

¾Check mains power cord for any damage before

charging.

¾Arrange for any damaged mains power cord to

be replaced by the manufacturer.

WARNING

Risk of injury and material damage due to

damaged Li-ion battery!

¾Prior to charging, check the Li-ion battery for

any damage.

¾Do not use or charge any damaged Li-ion

batteries.

CAUTION

Loss of capacity/performance due to prolonged

storage of the discharged Li-ion battery!

¾Store Li-ion batteries only in fully charged

condition and recharge stored batteries once

every month.

CAUTION

Destruction of the product, charging bay or Li-ion

battery when inserting the wrong type of battery

in the charging bay!

¾Insert Li-ion battery only in the appropriate

charging bay.

f

g

39

6

Econom CL/Econom CL Equipe/Econom CL Fitter cattle and horse clipping machine

Aesculap®

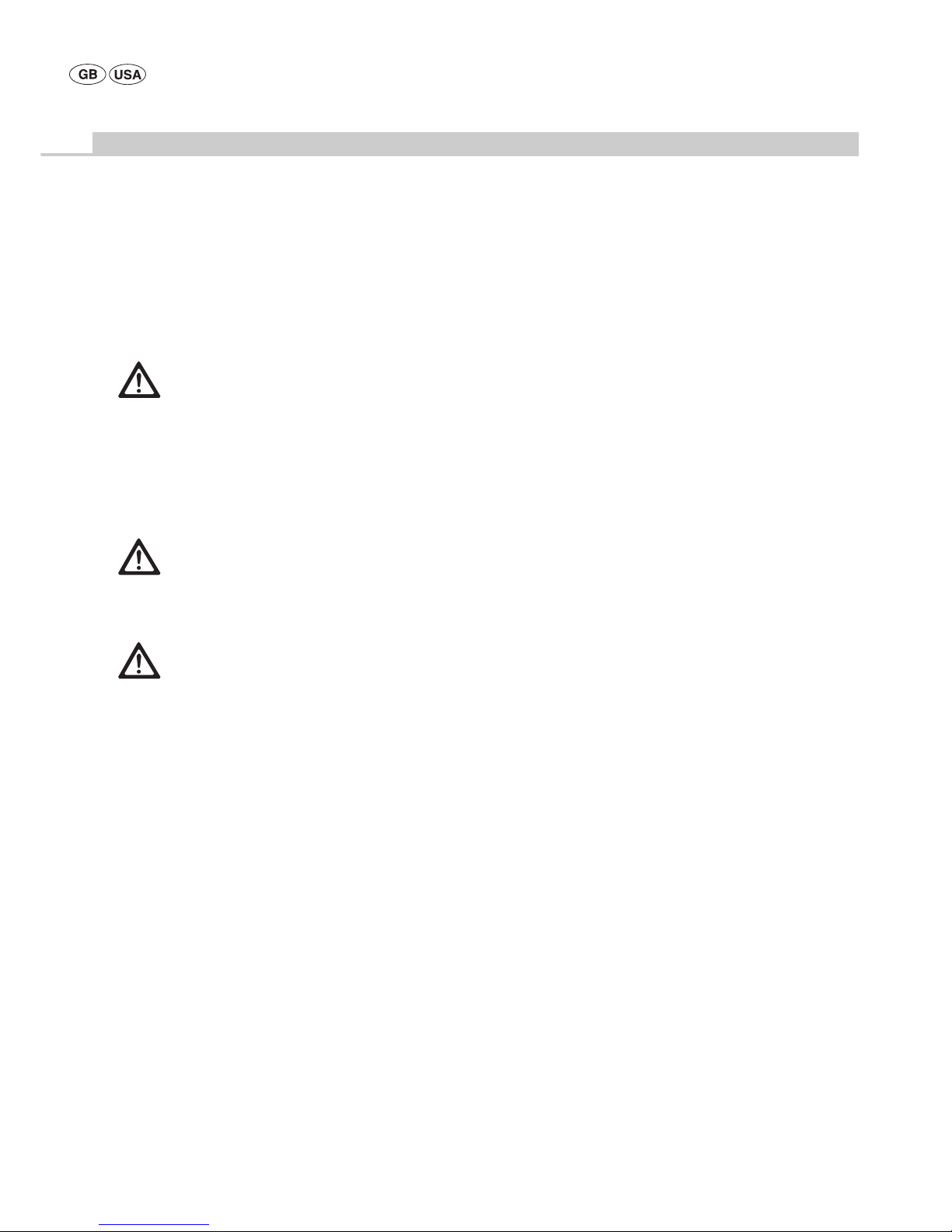

¾Remove the lithium ion battery 39, and push the charged replacement

lithium ion battery GT801 into the battery-operated clipping

machine g, see Fig. 2.

Fig. 2

¾Secure the lithium ion battery 39 using the battery lock f, see Fig. 3.

Fig. 3

4.5 Handling the cutter head

Lubricating the cutter head

¾Generously oil the cutter head at the lubrication point abefore

shearing each animal, see Fig. A.

¾Oil spring leaves 10 2 to 3 times daily with 3 to 4 drops of oil, see

Fig. C.

Lubricating the gear wheel

¾Unlocking and removing the lithium ion battery 39.

¾Remove both screws 6, see Fig. B.

¾Then turn the cutter head very slightly (about 15°) counterclockwise

and remove it from the motor shell.

¾Apply approximately 1 cm of grease on the two opposite points of the

gear wheel 11, see Fig. C.

¾Carefully place the cutter head on the motor. When re-attaching the

cutter head, ensure that it is turned 15° counterclockwise in such a

way that its lower flange engages with the groove of the motor

housing.

Changing the cutter plate

¾Unlocking and removing the lithium ion battery 39.

¾Loosen the locking cap 3and adjusting screw 4by approx. 2 turns, see

Fig. A.

¾Loosen both clamp screws 9, pull off the cutter plate 1forwards and

remove the upper cutter plate 2, see Fig. D and Fig. E.

¾Before inserting the upper cutter plate 2, ensure that the oscillating

block 8is in the intended recess of the oscillator 7, see Fig. E.

¾Insert the upper cutter plate 2. When doing so, ensure that both tips b

of the oscillator 7engage precisely in the holes cof the upper cutter

plate 2, see Fig. D.

39

f

39

CAUTION

Damage to the clipping machine or the cutter

head due to incorrect lubrication!

¾Only oil the cutter head when the machine is

running.

¾Never immerse the cutter head in liquid of any

kind!

¾Only use GT604 light lubricating oil.

CAUTION

Damage to the clipping machine or the gear wheel

due to incorrect lubrication!

¾Use only gear grease GT605.

¾Lubricate the gear wheel 1 to 2 times during

the shearing season.

7

¾Push the lower cutter plate 1below the heads of the clamping

screws 9all the way on to the cutter head shell and screw both

clamping screws 9tight.

¾Tighten the adjusting screw 4until both cutter plates are pressing

slightly against one another, see Fig. A.

Adjusting the plate pressure

Note

The plate pressure must be set with the machine running and without

auxiliary tools.

Note

If the plate pressure is too high, this results in the build-up of heat and

greater wear to the cutter plates.

¾Carefully loosen the locking cap 3and adjusting screw 4until the

upper cutter plate 2is no longer pressing against the lower cutter

plate 1(the sound of the motor becomes noticeably higher-pitched),

see Fig. A.

¾Screw in the adjusting screw 4until you feel slight resistance. From

this point, keep turning approximately one full sun and then tightened

the locking cap 3.

Cleaning the cutter head

¾The cutter head must be cleaned at least after each day of clipping

time or if it gets dirty.

¾Unlocking and removing the lithium ion battery 39.

¾Remove both screws 6, see Fig. B.

¾Then turn the cutter head very slightly (about 15°) counterclockwise

and remove it from the motor shell.

¾Remove the cutter plates, see Changing the cutter plate.

¾Thoroughly clean the interior part and individual parts of the cutter

head using a brush.

¾Insert the cutter plate and tighten, see Changing the cutter plate.

¾Lubricate the gear wheel, see Lubricating the gear wheel.

¾Carefully place the cutter head on the motor. When re-attaching the

cutter head, ensure that it is turned 15° counterclockwise in such a

way that its lower flange engages with the groove of the motor

housing.

¾Lubricate the cutter head, see Lubricating the cutter head.

Cleaning the air filter

¾Clean the airfilter 37/38 at least once per day or if it gets dirty.

¾Remove the airfilter 37/38 from the battery-operated clipping

machine, see Fig. G.

¾Thoroughly clean the airfilter 37/38 in warm water with a brush.

¾Leave the airfilter 37/38 to dry.

¾Clean the battery-operated clipping machine.

¾Place the airfilter 37/38 on the battery-operated clipping machine.

Re-sharpen the cutter plates.

¾In order to re-sharpen the cutter plates, contact Technical Service, see

Technical Service.

4.6 Storage

¾Clean the clipping machine and cutter plates thoroughly before

storing, see Reprocessing.

¾Store the clipping machine in a dry, dark and clean room.

5. Cutter plates

5.1 Cutter plates compatible with cutter head GT367

5.2 Recommended combinations

Art. no. Designation

GT501 Upper cutter plate with 15 cutting teeth

GT502 Lower cutter plate with 31 cutting teeth,

Cutting height: 3 mm

GT503 Upper cutter plate with 17 cutting teeth

GT504 Lower cutter plate with 18 cutting teeth,

Cutting height: 3 mm

GT505 Upper cutter plate with 23 cutting teeth

GT506 Lower cutter plate with 23 cutting teeth,

Cutting height: 3 mm

GT508 Lower cutter plate with 51 cutting teeth,

Cutting height: 1 mm

GT510 as GT506, but a cutting height of 5 mm

GT511 as GT502, but a cutting height of 1 mm

Combination Upper/lower plate Suitable for

closely spaced

teeth

GT501/GT502 Cattle and horses (regular

equipment for GT474 and

GT367)

GT501/GT511 Industrial shearing

GT505/GT508 (e.g. coat shearing)

medium spaced

teeth

GT505/GT506 Cattle, dogs and goats

GT505/GT510 Dogs and goats

widely spaced

teeth

GT503/GT504 Cattle, sheep with fine wool

and single sheep

8

Econom CL/Econom CL Equipe/Econom CL Fitter cattle and horse clipping machine

Aesculap®

6. Reprocessing

6.1 Cleaning/disinfection

¾Wipe the shell of the product with a lint-free cloth moistened with a

commercial disinfectant for wipe disinfection.

¾If necessary, after the appropriate exposure time, wipe off any residues

of the cleaning/disinfecting agent with a lint-free cloth moistened

with clean water.

¾Dry the product with a clean, lint-free cloth.

¾Clean the contacts in the charging bay with isopropanol or ethyl

alcohol and a cotton swab. Do not use corrosive chemicals.

¾If necessary, repeat the cleaning/disinfecting process.

6.2 Inspection and checking

¾Allow the product to cool down to room temperature.

¾Inspect the product after each cleaning and disinfecting cycle to be

sure it is: clean, functional, and undamaged.

¾Check the product for any damage, abnormal running noise,

overheating or excessive vibration.

¾Inspect the shearing head for broken, damaged or blunt cutting edges.

¾Set aside the product if it is damaged.

7. Maintenance

To ensure reliable operation, Aesculap recommends servicing the product

at least once a year.

DANGER

Risk of electric shock and fire hazard!

¾Before cleaning:

–Remove the mains plug from the charger.

–Unlock the lithium ion battery and remove

from the battery-operated clipping machine.

¾Do not use flammable or explosive cleaning or

disinfecting solutions.

¾Ensure that no fluids will penetrate the

product.

CAUTION

Damage to, or destruction of the product caused

by mechanical cleaning/disinfection!

¾Only clean and disinfect the product manually.

¾Do not sterilize the product under any

circumstances.

CAUTION

Risk of damage to the product due to

inappropriate cleaning/disinfecting agents!

¾Only use cleaning/disinfecting agents approved

for surface cleaning. Follow the manufacturer’s

instructions for the respective cleaning/

disinfecting agent.

¾Never immerse the product in water or

detergent.

¾Do not introduce any fluid into the charging

bays.

¾Clean the contacts in the charging bay,

applying extreme care.

9

8. Troubleshooting

8.1 Battery-operated clipping machine Econom CL/Econom CL Equipe/Econom CL Fitter

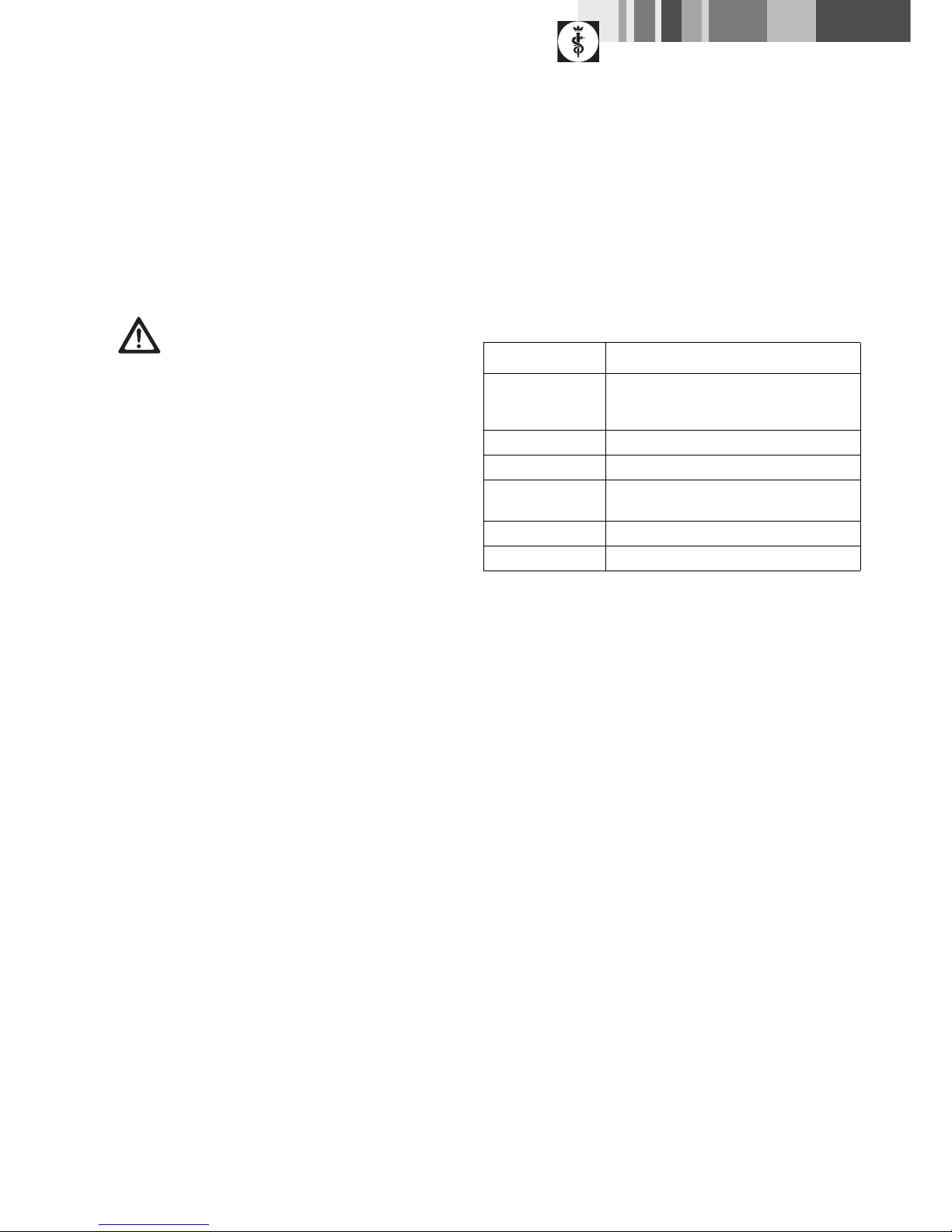

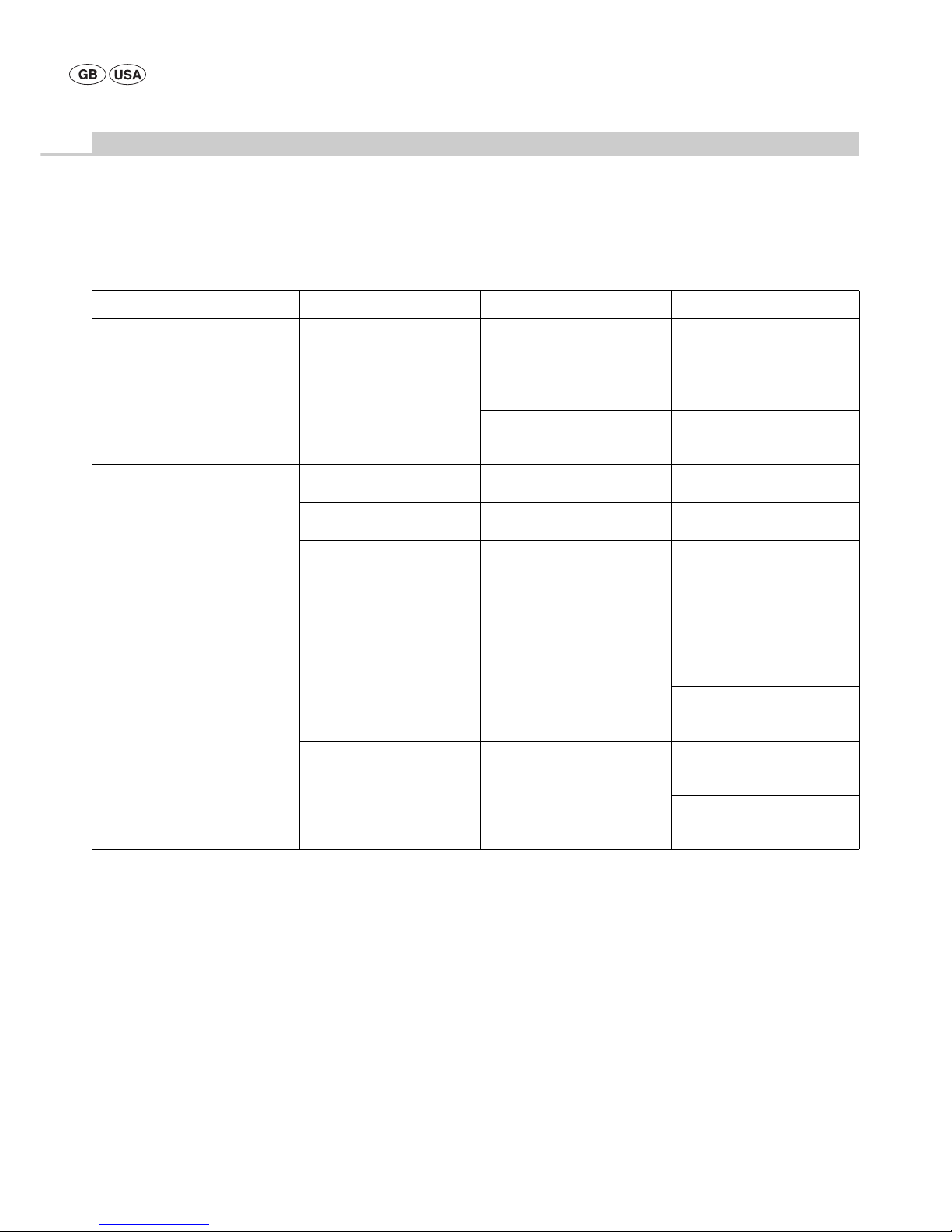

Malfunction Detection Cause Remedy

The battery-operated clipping machine

does not start

– Li-ion battery not activated Press button eon the lithium ion

battery

The LED of the on/off button 36

blinks twice per second

Li-ion battery not loaded Load Li-ion battery

– Li-ion battery defect Insert new Li-ion battery

– Li-ion battery not inserted Insert the Li-ion battery

The battery-operated clipping machine

pauses during operation

– Li-ion battery deactivated through

protective circuit

Switch the battery-operated

clipping machine off and on again

– Li-ion battery is empty Insert new Li-ion battery

10

Econom CL/Econom CL Equipe/Econom CL Fitter cattle and horse clipping machine

Aesculap®

8.2 Charger and Li-ion battery

Malfunction Detection Cause Remedy

Charger not working The "Battery" LED indicator is not

lit up

Mains power cord not plugged in Plug mains power cord into the

device socket on the charger and

into the socket of the mains power

supply

Li-ion battery not loaded Mains power cord defective Replace mains power cord

Li-ion battery defect Send Li-ion battery to

manufacturer for repair, see

Technical Service

Li-ion battery cannot be loaded Li-ion battery plugged in, charge

state indicator does not light up

Charger contacts dirty Clean the contacts in the charging

bay, see Reprocessing

– Charger contacts damaged Send charger to manufacturer for

repair, see Technical Service

– Li-ion battery defect Send Li-ion battery to

manufacturer for repair, see

Technical Service

– Charger defect Send charger to manufacturer for

repair, see Technical Service

– Too high a temperature is measured

in the lithium ion battery during the

charging process

Remove the Li-ion battery from the

charging bay, leave to cool and

repeat the charging process

If the problem occurs again: Send

Li-ion battery to manufacturer for

repair, see Technical Service

– Battery charging error or Li-ion

battery defect

Remove the Li-ion battery from the

charging bay and repeat the

charging process

If the problem occurs again: Send

Li-ion battery to manufacturer for

repair, see Technical Service

11

9. Technical Service

Modifications carried out on medical technical equipment may result in

loss of guarantee/warranty rights and forfeiture of applicable licenses.

Service addresses

Albert Kerbl GmbH

Felizenzell 9

84428 Buchbach / Germany

Phone: +49 (0) 8086 933-100

Fax: +49 (0) 8086 933-500

E-Mail: [email protected]

www.kerbl.com

Other service addresses can be obtained from the address indicated above.

10. Accessories/Spare parts

WARNING

Risk of injury and/or malfunction!

¾Do not modify the product.

Art. no. Designation Design Power cord or power supply

unit

Li-ion battery Complete charging

station

Accessories

GT804/

GT806

Econom CL Europe

outside of

Great Britain

TA012170

European plug, black

L=1.8 m

GT801 GT803 GT604

Special lubricating

oil for cutter plates

and cutter head

GT605

Gear grease (tube)

GT814/

GT816

Econom CL Equipe

GT834 Econom CL Fitter

GT804G/

GT806G

Econom CL Great Britain TA012169

GB plug, black,

L=1.8 m

GT814G/

GT816G

Econom CL Equipe

GT834G Econom CL Fitter

GT804K/

GT806K

Econom CL USA TA012168

2-pin connector plug, black,

L=1.8 m

GT814K/

GT816K

Econom CL Equipe

GT834K Econom CL Fitter

GT804A/

GT806A

Econom CL Australia TA013657

2-pin connector plug, black,

L=1.8 m

GT814A/

GT816A

Econom CL Equipe

GT834A Econom CL Fitter

12

Econom CL/Econom CL Equipe/Econom CL Fitter cattle and horse clipping machine

Aesculap®

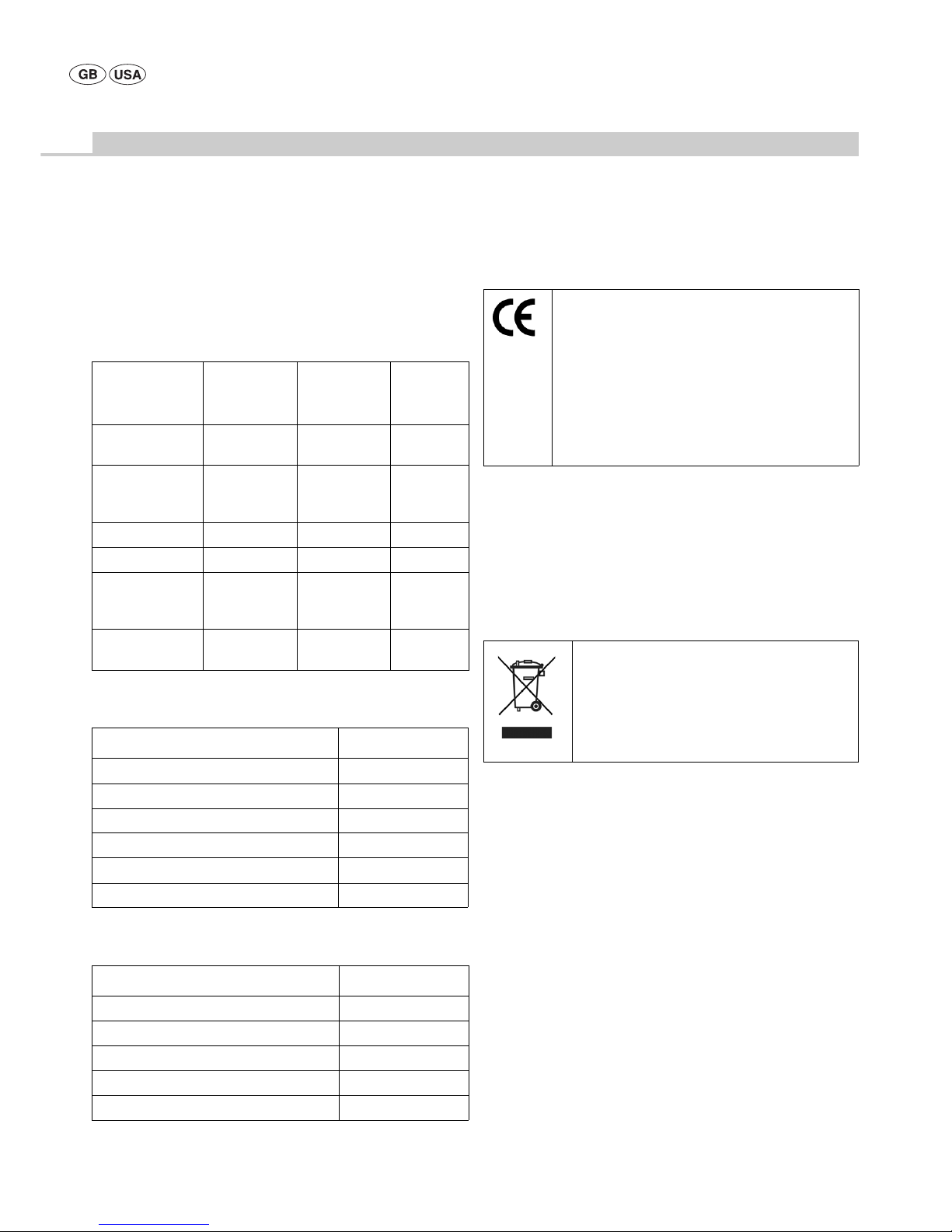

11. Technical Data

11.1 Battery-operated clipping machine Econom CL/

Econom CL Equipe/Econom CL Fitter

11.2 Charger

11.3 Li-ion battery

11.4 Declaration of conformity

12. Disposal

Electrical tools, accessories and packaging should be sent for

environmentally responsible recycling.

12.1 For EU countries only

12.2 Li-ion battery

Do not dispose of lithium ion batteries in domestic waste, fire or water.

Defective or used lithium ion batteries must be collected, recycled or

disposed of in an environmentally-friendly way according to Directive

2006/66/EC.

GT800

Econom CL

GT810

Econom CL

Equipe

GT834

Econom CL

Fitter

Stroke rate max.

27501/min

max.

2 250 1/min

max.

3 000 1/min

Running time with

a lithium ion

battery

approx.

70 min

approx.

80 min

approx.

70 min

Nominal voltage max. 21.6 V max. 21.6 V max. 21.6 V

Capacity max. 2.6 A max. 2.6 A max. 2.6 A

Weight (with

shearing head and

battery)

1 250 g 1 250 g 1 250 g

Quality marks TÜV-GS, CE, UL,

CSA

TÜV-GS, CE, UL,

CSA

CE, UL, CSA

GT803

Voltage range (current consumption) 100 V to 240 V

Frequency 50 Hz to 60 Hz

Charging voltage/Output voltage max. 25.2 V

Charging current/Output current max. 2.6 A

Weight (with cable and power supply unit) 764 g

Quality marks TÜV-GS, CE, UL, CSA

GT801

Cell type Li

Nominal voltage 21.6 V

Capacity 2.6 Ah

Charging time approx. 70 min

Quality marks TÜV-GS, CE, UL, CSA

We declare under our sole responsibility that this product

complies with the following standards and regulatory

documents:

2004/108/EC EMC Guidelines:

DIN EN 60335-1

DIN EN 60335-2-8

Safety of household and similar electrical appliances

– general requirements

– for hair shearing machines

Aesculap Suhl GmbH

Do not dispose of electrical tools in domestic waste!

According to European Directive 2012/19/EU on old

electrical and electronic appliances and its

implementation in national law, electrical tools that

are no longer suitable for use must be separately

collected and sent for environmentally responsible

recycling.

13

13. Two year guarantee

Dear Customer,

Many thanks for choosing one of our products.

For decades, the name Aesculap has stood for proven quality and first-

class service. We are known to provide innovative, high-performance

products for our customers. Aesculap manufactures high-quality devices

and can assure you that it uses high-quality materials and careful

manufacturing processes. We would like to point out to you that we are

not liable for defects in our products, if these are caused by improper use,

normal wear or are caused by the product being improperly used or if

inappropriate or not properly functioning third-party products are used.

Parts that are typically subject to wear, and for which we are therefore not

liable, are the battery and shearing head. Material defects that do not

affect or only negligibly affect the value or function of the product are

also excluded from our warranty.

If we are liable under our warranty, we reserve the right to repair or

replace the product.

14

Rinder- und Pferdeschermaschine Econom CL/Econom CL Equipe/Econom CL Fitter

Aesculap®

Übersicht Symbole am Produkt

Inhaltsverzeichnis

1 Sichere Handhabung.................................................................................. 15

2 Gerätebeschreibung ................................................................................... 15

2.1 Lieferumfang................................................................................................ 15

2.2 Zum Betrieb erforderliche Komponenten............................................. 15

2.3 Verwendungszweck.................................................................................... 15

2.4 Funktionsweise ............................................................................................ 16

3 Vorbereiten ................................................................................................... 16

4 Arbeiten mit Akku-Schermaschine, Ladegerät und Li-Ionen-Akku 16

4.1 Bereitstellen ................................................................................................. 16

4.2 Funktionsprüfung........................................................................................ 16

4.3 Ladegerät anschließen/Li-Ionen-Akku laden ...................................... 17

4.4 Li-Ionen-Akku wechseln ........................................................................... 17

4.5 Handhabung des Scherkopfs ................................................................... 18

4.6 Lagerung........................................................................................................ 19

5 Schneideplatten .......................................................................................... 19

5.1 Schneideplatten passend zu Scherkopf GT367................................... 19

5.2 Empfohlene Kombinationen..................................................................... 19

6 Aufbereitung ................................................................................................ 20

6.1 Reinigung/Desinfektion............................................................................. 20

6.2 Kontrolle und Prüfung............................................................................... 20

7 Wartung......................................................................................................... 20

8 Fehler erkennen und beheben ................................................................. 21

8.1 Akku-Schermaschine Econom CL/Econom CL Equipe/

Econom CL Fitter......................................................................................... 21

8.2 Ladegerät und Li-Ionen-Akku.................................................................. 22

9 Technischer Service.................................................................................... 23

10 Zubehör/Ersatzteile .................................................................................... 23

11 Technische Daten........................................................................................ 24

11.1 Akku-Schermaschine Econom CL/Econom CL Equipe/

Econom CL Fitter......................................................................................... 24

11.2 Ladegerät....................................................................................................... 24

11.3 Li-Ionen-Akku .............................................................................................. 24

11.4 Komformitätserklärung ............................................................................. 24

12 Entsorgung.................................................................................................... 24

12.1 Nur für EU-Länder ...................................................................................... 24

12.2 Li-Ionen-Akku .............................................................................................. 24

13 2 Jahre Gewährleistung ............................................................................ 25

Pos.

Art.-Nr.

Anzahl

Benennung

1GT502 1

Untere Schneideplatte (GT804–GT816/GT834)

2GT501 1

Obere Schneideplatte (GT804/GT806/GT834)

GT505 1 Obere Schneideplatte (GT814/GT816)

3GT610405 1 Rändelmutter

4GT367205 1 Regulierschraube

6TA010017 2 Schraube

7GT367201 1 Schwinger

8GT610304 1 Schwingklötzchen

9GT610010 2 Klemmschraube

10 GT367202 6 Schwingfederblatt

11 GT367812 1 Stirnrad mit Exzenterwelle

15 TA008295 2 Führungsstift

16 GT367801 1 Scherkopfgehäuse montiert

17 TA005091 2 Schraube

18 GT367802 1 Distanzteil, links

19 GT367803 1 Distanzteil, rechts

20 TA007765 1 Senkschraube

25 GT610307 1 Federbrücke

26 GT367207 1 Fixierschraube

27 GT367804 1 Schwinger, montiert

35 TA009222 1 Schraubendreher

36 GT800249 1 Ein-/Aus-Taster (mit LED)

37 GT800804 1 Luftfilter (blau)

Econom CL

38 GT800844 1 Luftfilter (bordeaux)

Econom CL Equipe

39 GT801 1 Lithium-Ionen-Akku

40 GT803 1 Ladegerät

a– 1 Ölstelle Akku-Schermaschine

b– 1 Spitzen des Schwingers

c– 1 Bohrungen der oberen Schneidplatte

d– 1 Ladezustandsanzeige Li-Ionen-Akku

e– 1 Taste des Li-Ionen-Akkus

f– 1 Akkuverriegelung

gGT800/

GT810

1 Akku-Schermaschine

– GT604 1 Spezialöl für Scherkopf und Schneideplat-

ten

GT605 1 Getriebefett (Tube)

Achtung, allgemeines Warnzeichen

Achtung, Begleitdokumente beachten

Kennzeichnung von Elektro- und Elektronikgeräten ent-

sprechend Richtlinie 2012/19/EU (WEEE), siehe Entsor-

gung

15

1. Sichere Handhabung

¾Vor der Anwendung des Produkts Funktionsfähigkeit und ordnungsge-

mäßen Zustand prüfen.

¾Ladegerät und Li-Ionen-Akkus bei Raumtemperatur aufbewahren.

¾Ladegerät und Li-Ionen-Akkus trocken halten.

¾Vor dem ersten Einsatz Li-Ionen-Akkus laden.

¾Um Schäden durch unsachgemäßen Aufbau oder Betrieb zu vermeiden

und die Gewährleistung und Haftung nicht zu gefährden:

– Produkt nur gemäß dieser Gebrauchsanweisung verwenden.

– Sicherheitsinformationen und Instandhaltungshinweise einhalten.

– Nur Aesculap-Produkte miteinander kombinieren.

¾Gebrauchsanweisung für den Anwender zugänglich aufbewahren.

¾Gültige Normen einhalten.

¾Sicherstellen, dass die elektrische Installation des Raums den IEC-

Anforderungen entspricht.

¾Netzverbindungen durch ziehen am Gerätestecker lösen, nie durch Zie-

hen am Kabel.

¾Produkt nicht in explosionsgefährdeten Bereichen einsetzen.

¾Kein beschädigtes oder defektes Produkt verwenden. Beschädigtes Pro-

dukt sofort aussortieren.

2. Gerätebeschreibung

2.1 Lieferumfang

2.2 Zum Betrieb erforderliche Komponenten

• Akku-Schermaschine Econom CL/Econom CL Equipe/Econom CL Fitter

• Ladegerät

• Netzanschlussleitung (mit Gerätestecker)

• Li-Ionen-Akku

2.3 Verwendungszweck

Akku-Schermaschine Econom CL/Econom CL Equipe/

Econom CL Fitter

Die Akku-Schermaschine Econom CL/Econom CL Equipe/Econom CL Fitter

wird zum Scheren von Großtieren wie Rinder, Pferden und großen Hunden

verwendet.

Ladegerät GT803/Li-Ionen-Akku GT801

Das Ladegerät GT803 wird zum Laden des Li-Ionen-Akkus GT801 einge-

setzt.

GEFAHR

Lebensgefahr durch elektrischen Stromschlag!

¾Produkt nicht öffnen.

¾Produkt nur an ein Versorgungsnetz mit

Schutzleiter anschließen. Art.-Nr. Bezeichnung

GT800

GT810

Akku-Schermaschine Econom CL,

Econom CL Equipe bzw.

Econom CL Fitter

GT801 Li-Ionen-Akku

GT803 Ladegerät

siehe Zubehör/

Ersatzteile

Netzanschlussleitung (mit Gerätestecker)

TA013895 Gebrauchsanweisung

GT604 Ölflasche

16

Rinder- und Pferdeschermaschine Econom CL/Econom CL Equipe/Econom CL Fitter

Aesculap®

2.4 Funktionsweise

Akku-Schermaschine Econom CL/Econom CL Equipe/

Econom CL Fitter

Die Akku-Schermaschine Econom CL/Econom CL Equipe/Econom CL Fitter

wird mit dem Ein-/Aus-Taster 36 ein- und ausgeschaltet.

Hinweis

Um ein versehentliches Ein-/Ausschalten der Maschine zu vermeiden,

reagiert der Ein-Aus-Taster erst nach einer Betätigung >0,5 s.

Ladegerät GT803/Li-Ionen-Akku GT801

Das Ladegerät GT803 ist für einen Netzspannungsbereich von 100 V bis

240 V und von 50 Hz bis 60 Hz konzipiert.

Zur Herstellung der Betriebsbereitschaft wird das Ladegerät GT803 mit

dem Netzstecker an das Versorgungsnetz angeschlossen.

Das Ladegerät GT803 verfügt über einen Ladeschacht.

Mit dem Einstecken des Li-Ionen-Akkus in die Ladestation startet der

Ladevorgang automatisch.

Die Ladezeit hängt vom Ladezustand und der Kapazität des Li-Ionen-

Akkus ab.

Ladeprinzip

Die Li-Ionen-Akkus werden mit konstanten Stromimpulsen aufgeladen.

Der Ladezustand des Li-Ionen-Akkus wird während der Aufladung über-

wacht. Durch die Überwachung der Ladekurve wird eine 100 %-Ladung

ohne Überladung sichergestellt.

Zusätzlich werden Akku-Temperatur und Ladezeit überwacht.

Die Ladezustandsanzeige ddes Li-Ionen-Akkus hat 5 LEDs. Jede LED steht

für 20 % Ladevolumen. Befindet sich der Akku im Ladevorgang, blinkt die

LED des jeweiligen Ladezustands. Wenn alle LEDs dauerhaft leuchten, ist

der Akku vollständig geladen.

Ladezeit

Bei Erreichen der maximalen Ladezeit wird der Ladevorgang abgebrochen.

Die Ladezeit beträgt ca. 70 min.

3. Vorbereiten

Wenn die folgenden Vorschriften nicht beachtet werden, übernimmt

Aesculap insoweit keinerlei Verantwortung.

¾Beim Aufstellen und Betrieb des Produkts einhalten:

– die nationalen Installations- und Betreiber-Vorschriften,

– die nationalen Vorschriften über Brand- und Explosionsschutz,

– Anwendungshinweise gemäß IEC-/VDE-Bestimmungen.

4. Arbeiten mit Akku-Schermaschine,

Ladegerät und Li-Ionen-Akku

4.1 Bereitstellen

Zubehör anschließen

Zubehörkombinationen, die nicht in der Gebrauchsanweisung erwähnt

sind, dürfen nur verwendet werden, wenn sie ausdrücklich für die vorge-

sehene Anwendung bestimmt sind. Leistungsmerkmale sowie Sicherheits-

anforderungen dürfen nicht nachteilig beeinflusst werden.

4.2 Funktionsprüfung

Akku-Schermaschine Econom CL/Econom CL Equipe/

Econom CL Fitter

¾Sichtprüfung durchführen.

¾Sicherstellen, dass Luftfilter 37/38 korrekt sitzt, siehe Abb. G.

¾Li-Ionen-Akku 39 in Maschinenschacht schieben und verriegeln.

¾Ladezustand des Akkus prüfen: Taster edrücken, siehe Abb. F.

¾Die Ladezustandsanzeige dzeigt den Ladezustand an.

Hinweis

Um zu verhindern dass sich der Li-Ionen-Akku bei Nichtgebrauch der

Maschine entlädt, wird die elektronische Verbindung des Li-Ionen-Akku

zur Steuerung der Akku-Schermaschine nach 1 h getrennt.

¾Li-Ionen-Akku 39 reaktivieren: Taster ebetätigen, siehe Abb. F.

Alle LEDs der Ladezustandsanzeige dleuchten auf.

Ladegerät/Li-Ionen-Akku

¾Sichtprüfung durchführen.

¾Vor Anschluss des Produkts an das Versorgungsnetz:

–Netzanschlussleitung auf mögliche Beschädigungen prüfen.

–Produkt auf mögliche Beschädigungen prüfen (z. B. Kontakte des

Ladeschachts auf verbogene Kontakte prüfen).

¾Netzanschlussleitung in Gerätestecker an der Ladestation stecken.

¾Netzstecker in Steckdose des Versorgungsnetzes stecken.

¾Li-Ionen-Akku 39 in Ladeschacht des Ladegeräts stellen und aufladen,

siehe Abb. F.

17

4.3 Ladegerät anschließen/Li-Ionen-Akku laden

Hinweis

Das Ladegerät kann von Kindern ab 8 Jahren und darüber sowie von Perso-

nen mit verringerten physischen, sensorischen oder mentalen Fähigkeiten

oder Mangel an Erfahrung und Wissen benutzt werden, wenn Sie beauf-

sichtigt oder bezüglich des sicheren Gebrauchs des Gerätes unterwiesen

wurden und die daraus resultierenden Gefahren verstehen.

¾Kinder nicht mit dem Gerät spielen lassen.

¾Reinigung und Wartung des Ladegeräts nicht von Kindern ohne Beauf-

sichtigung durchführen lassen.

Hinweis

Der Li-Ionen-Akku erwärmt sich leicht beim Ladevorgang.

Hinweis

Wenn nicht mit dem Ladegerät gearbeitet wird, muss die Netzanschlusslei-

tung von der Steckdose getrennt werden.

¾Nur Aesculap Ladegerät GT803 zum Aufladen der Lithium-Ionen-Akkus

verwenden.

¾Ladegerät 40 anschließen: Gerätestecker der Netzanschlussleitung in

Ladegerät stecken.

¾Netzstecker der Netzanschlussleitung in Steckdose stecken.

¾Li-Ionen-Akku 39 in Ladeschacht des Ladegeräts stecken und aufla-

den, siehe Abb. F.

Die LEDs der Ladezustandsanzeige ddes Li-Ionen-Akku blinken gemäß

dem aktuellen Ladestatus. Wenn alle LEDs dauerhaft leuchten, ist der

Akku vollständig geladen.

4.4 Li-Ionen-Akku wechseln

¾Akku-Schermaschine gmit dem Scherkopf nach unten halten, damit

der Li-Ionen-Akku 39 beim Lösen nicht herunterfällt, siehe Abb. 1.

¾Akkuverriegelung fmit dem Daumen lösen.

Abb. 1

WARNUNG

Brandgefahr bei Kurzschluss der Pole durch Flüs-

sigkeiten oder Metallteile!

¾Li-Ionen-Akku nicht kurzschließen.

WARNUNG

Verletzungsgefahr durch beschädigte Netzan-

schlussleitung!

¾Netzanschlussleitung vor dem Laden auf

Beschädigungen prüfen.

¾Beschädigte Netzanschlussleitung durch Her-

steller ersetzen lassen.

WARNUNG

Verletzungsgefahr und Sachschäden durch

beschädigten Li-Ionen-Akku!

¾Li-Ionen-Akku vor dem Laden auf Beschädi-

gungen prüfen.

¾Beschädigten Li-Ionen-Akku nicht verwenden

oder aufladen.

VORSICHT

Verlust der Kapazität/Leistungsfähigkeit des ent-

ladenen Li-Ionen-Akku durch längere Lagerung!

¾Li-Ionen-Akku bei längerer Lagerung nur voll-

geladen einlagern und einmal pro Monat nach-

laden.

VORSICHT

Zerstörung von Produkt, Ladeschacht oder Li-

Ionen-Akku durch Stecken eines falschen Akku-

typs in den Ladeschacht!

¾Li-Ionen-Akku nur in den dafür vorgesehenen

Ladeschacht stecken.

f

g

39

18

Rinder- und Pferdeschermaschine Econom CL/Econom CL Equipe/Econom CL Fitter

Aesculap®

¾Li-Ionen-Akku 39 herausziehen, laden und/oder geladenen Ersatz-Li-

Ionen-Akku GT801 in Akku-Schermaschine gschieben, siehe Abb. 2.

Abb. 2

¾Li-Ionen-Akku 39 mit Akkuverriegelung fsichern, siehe Abb. 3.

Abb. 3

4.5 Handhabung des Scherkopfs

Scherkopf ölen

¾Scherkopf über Ölstelle avor jedem Tier reichlich ölen, siehe Abb. A.

¾Federblätter 10 2–3 mal täglich mit 3–4 Tropfen ölen, siehe Abb. C.

Zahnrad fetten

¾Li-Ionen-Akku 39 entriegeln und entfernen.

¾Beide Schrauben 6herausdrehen, siehe Abb. B.

¾Bei Blick auf den Scherkopf diesen um ca. 15° nach links verdrehen und

vom Motorgehäuse abnehmen.

¾Ca. 1 cm Fett auf zwei gegenüberliegende Stellen des Zahnrades 11

auftragen, siehe Abb. C.

¾Scherkopf vorsichtig auf den Motor stecken. Dabei sicherstellen, dass

der Scherkopf um ca. 15° nach links verdreht aufgesteckt wird und die

untere Nase in die Nut des Motorgehäuses greift.

Schneideplatten wechseln

¾Li-Ionen-Akku 39 entriegeln und entfernen.

¾Rändelmutter 3lösen und Regulierschraube 4ca. 2 Umdrehungen

herausdrehen, siehe Abb. A.

¾Beide Klemmschrauben 9lösen, die untere Schneideplatte 1nach vorn

abziehen und die obere Schneideplatte 2entnehmen, siehe Abb. D und

Abb. E.

¾Vor dem Einlegen der oberen Schneideplatte 2sicherstellen, dass sich

Schwingklötzchen 8in der dafür vorgesehenen Aussparung des

Schwingers 7befindet, siehe Abb. E.

¾Obere Schneideplatte 2einsetzen. Dabei sicherstellen, dass beide

Spitzen bdes Schwingers 7genau in die Bohrungen cder oberen

Schneideplatte 2eingreifen, siehe Abb. D.

¾Untere Schneideplatte 1unter den Köpfen der Klemmschrauben 9bis

zum Anschlag an das Scherkopfgehäuse schieben und beide

Klemmschrauben 9festziehen.

¾Regulierschraube 4eindrehen, bis beide Schneideplatten leicht aufei-

nanderdrücken, siehe Abb. A.

39

f

39

VORSICHT

Beschädigung der Schermaschine oder des Scher-

kopfs durch falsches Ölen!

¾Scherkopf nur bei laufender Maschine ölen.

¾Maschine und Scherkopf nicht in Flüssigkeiten

tauchen.

¾Nur Leichtschmieröl GT604 verwenden.

VORSICHT

Beschädigung der Schermaschine oder des Zahn-

rads durch falsches Fetten!

¾Nur Getriebefett GT605 verwenden.

¾Zahnrad 1-2 mal je Schursaison fetten.

This manual suits for next models

2

Table of contents

Languages:

Other Aesculap Power Tools manuals

Popular Power Tools manuals by other brands

DUROFIX

DUROFIX RZ6008 Series Product information manual

Viega

Viega 4296.2XL Instructions for use

Milwaukee

Milwaukee 4777 Operating instructions and parts list

Bostitch

Bostitch SB-150SX Operation and maintenance manual

Ingersoll-Rand

Ingersoll-Rand 1701 Series Product information

jbc

jbc AP250 instruction manual