AFFIX MADW-AGR Series User manual

Assembly Manual

Double Width MADW-AGR Series

EN1004-1 Class 3

No: CE/21-22/044

Aluminium Double Width Mobile Towers

MADW 520 - AGR

EN1004-1 37/11 XXXD

This AFFIX Tower is a mobile access tower manufactured in our ISO 9001

accredited facility.

This AFFIX Tower is a mobile access tower manufactured in our ISO 9001

accredited facility.

This user guide provides you with step by step instructions to ensure your

system is assembled easily and safely, using the AGR (Advanced Guard Rail)

method.

This user guide provides you with step by step instructions to ensure your

system is assembled easily and safely, using the AGR (Advanced Guard Rail)

method.

01EN1004-1 Certified

WARNING

NEVER FORGET TO LOCK THE

CASTOR WHEELS

DESCRIPTION:

The Advanced Guard Rail method:

The Advanced Guardrail (AGR) method is one of the two permitted ways of assembling a tower

while safeguarding the Scaffolder from the risk of falling.

An AGR tower uses prefabricated frames to provide structural rigidity and stability to the tower

instead of using the horizontal and diagonal braces used for the same purpose in the traditional

3T assembly method.

As each new level is added onto a tower, the scaffolder first installs the AGR frames and tower

frames from a safely guarded platform below. Once the AGR frames are in place, platforms for

the next level are installed such that the two uppermost horizontal rungs on the AGR frames

form the midrail and guardrail above the platform level. This process repeats until the tower

reaches the required height.

Compliances:

The Affix MADW Mobile Tower has been tested and certified to EN1004-1:2020 by TUV, India.

The Affix MADW Series Mobile Tower are versatile and user-friendly aerial solution for all

access needs. It gives a work platform for use by a maximum of two people, with weight evenly

distributed across the platform. The tower can be easily erected and with highly customizable

assembly it meets almost all the site constraints and provides safe and efficient working

platform. The key safety feature is the smart locking claws provided for the horizontal and

diagonal bracings. It allows an instant lock-up performed by single hand use, however, with the

reverse unlocking plug, two hands are needed to unplug the bracing.

The information and instructions included in this manual are provided to help get the best

possible service from your MADW Series Mobile Tower. This user guide provides you with step

by step instructions to ensure your system is assembled easily and safely, using the AGR

(Advanced Guard Rail method.

02

Maximum Safe Working Loads

The safe working load of the tower is 750 kgs including its own weight. The

maximum safe working load of any individual platform is 250 kgs evenly

distributed. If the tower is to be used in an application outside the scope of

EN1004, contact your supplier or the manufacturer, Affix Scaffolding WLL,

for advice on loadings.

RECOMMENDATIONS :

Recommend a minimum of two people to assemble, dismantle and move the platform tower.

Check that all components are on site and in good working order.

Towers must always be climbed from the inside of the assembly using the ladder.

Lifting of components must be done inside the effective base area of the tower.

Moving the tower must only be done by manual effect from the base of the tower.

When moving tower be aware of overhead hazards (e.g. electric cables).

No personnel or material to be on the platform whilst the tower is being moved.

Damaged components or components from other tower systems must never be used.

Stabilizers should always be fitted when specified. Use the stabilizer shown on the component

list according to the tower height.

Outdoor scaffold towers should, wherever possible, be secured to a building or fixed structure.

It is good practice to tie scaffold towers of any height, especially when unattended, or exposed to

windy conditions.

Do Not use boxes or steps to gain additional height.

Do Not lift or suspend an assembled mobile tower.

Beware of horizontal loads which can lead to instability of the tower. The Max. side force is 20kg.

Ensure that the assembly location is checked to prevent hazards during assembly or moving

and while working on the tower. Particular attention should be given to the ground condition,

whether level or sloping, obstructions and wind conditions. The ground condition must be

capable of supporting the tower structure.

03USAGE ADVICE

Safety Checklist :Safety Checklist :

Air speed and resultant action to be taken

Mobile towers - AGR Method Checklist

Beufort Scale

01 mph

12 mph

17 mph

25 mph

40 mph

Calm, smoke rises easily upwards No action needed

Cease work

No action needed, keep a watch

If expected, dismantle the tower

If expected, tie tower to a rigid

structure

Moderate breeze, raises dust

Gale force, cannot even walk

Raises loose papers, leaves and small

twigs move

Strong breeze, tree branches bend, unable

to use umbrella

3

4

5

6

Description Air Speed Action to be taken

Ensure all brace claws operate and lock correctly prior to erection

Inspect components prior to use

Tower upright and level

Castors locked and legs correctly adjusted

Diagonal braces fitted

Stabilizers/outriggers fitted as specified

Platforms located and wind-locks on

Toe boards located

Check that the guardrails are fitted correctly

04USAGE ADVICE

WARNING

NEVER STAND ON AN

UNGUARDED PLATFORM

Safe working load on the working platform is 250kgs evenly distributed.

ASSEMBLY PROCESS :

PREPARATIONPREPARATION

Locate the tower, ensuring ground is level.

Check the locking triggers in the bracing hooks such that they are working properly.

Lock the castor by moving the brake lever fully down.

Sort the braces into horizontal and diagonal braces, the diagonals are slightly longer.

Also note that the braces are differently color coded.

The load on the tower should not exceed 750kgs.

The maximum recommended tower height is 7M for outdoors and 11M

for indoors.

SAFE WORKING LOADS AND

HEIGHTS

05

FIRST LEVEL

Step 1

DO NOT USE Hammer.DO NOT USE Hammer.

Insert the Castor Wheels with the jack

pipe inside the bottom of the tubes of

the 1st level 2 Rung Ladder Frame and

2 Rung Span Frame.

Step 2.1Step 2.1

Hook both the bottom 2 Horizontal Braces

horizontally to the Span frame and the

Ladder Frame's vertical pipes, just above

the 1st rung.

Step 2.2Step 2.2

Lock all the four wheels by pressing the

lock gear with foot.

One person should hold the frame in

upright position during this step.

Step 2.3Step 2.3

Step 2

06ASSEMBLY

SECOND LEVEL

Insert both the 2nd level 4 Rung Span

Frame and the 4 Rung Ladder Frame on

the respective sides into the corresponding

spigots.

For clamping instructions refer to

the Clamping Instructions section on

Page 12.

Step 3.1Step 3.1

Step 3.2Step 3.2

Step 4.1Step 4.1

Hook the Diagonal Brace to the 1st Rung

of the 1st level Span frame at one end and

the other end should be hooked to the 1st

Rung of the 2nd level Ladder frame.

Step 4.2Step 4.2

Hook the 2nd Diagonal Brace to the 1st

Rung of the 2nd level Ladder frame at one

end and the other end should be hooked

to the 1st Rung of the 1st level Span frame.

Step 4

Step 3

One person should hold the frame in upright

position during this step.

Step 4.3Step 4.3

Level the structure using a Spirit Level on

the Rungs and the braces. Adjust using

the adjustable jack.

07ASSEMBLY

Step 5.1Step 5.1

Hook the top rung of the AGR frame to

the top rung of the 2nd level frames and

the bottom rung of the AGR frame should

be hooked to the 1st rung of the 2nd level

frames.

Step 5.2

Repeat Step 5.1 for the opposite side but

slide it towards the frame ladders to

provide cover to the platform.

Step 6

Step 5

Clamp the 4 Stabilizers on all 4 corners

as per the Components Table on Page

no. 17. For detailed instructions on

installation refer to Page no.15.

08ASSEMBLY

Step 7

Step 8.1Step 8.1

Step 8

Hook the Intermediate Trapdoor platform

on the 2nd Rung of the 2nd level frames.

Make sure the trapdoor is towards the

ladder side.

09ASSEMBLY

Step 7.1Step 7.1

Insert both the 3rd level 4 Rung Span

Frame and the 4 Rung Ladder Frame on

the respective sides into the corresponding

spigots.

For clamping instructions refer to

the Clamping Instructions section on

Page 12.

THIRD LEVEL

Step 10.1Step 10.1

Step 9

Step 10

10ASSEMBLY

Step 9.1Step 9.1

Hook the Diagonal Brace to the 3rd Rung

of the 2nd level Span frame at one end

and the other end should be hooked to the

1st Rung of the 3rd level Ladder frame.

Hook the 2nd Diagonal Brace to the 3rd

Rung of the 2nd level Ladder frame at one

end and the other end should be hooked

to the 1st Rung of the 3rd level Span frame.

Step 9.2Step 9.2

Hook the top rung of the AGR frame to

the top rung of the 3rd level frames and

the bottom rung of the AGR frame should

be hooked to the 1st rung of the 3rd level

frames.

Step 11.1Step 11.1

Step 11

11ASSEMBLY

Step 11.2Step 11.2

Hook the Working Trapdoor platform on

the 2nd Rung of the 3rd level frames.

Make sure the trapdoor is towards the

ladder side.

Also hook the Fixed platform beside the

Trapdoor platform on the same rungs

Step 12.1Step 12.1

Step 12

Step 12.2Step 12.2

Clamp the 4 plastic toe-board holders on

all the 4 corners of the working platform

level, around the working platform.

For more details, refer to Toe-board

Assembly Details on Page 12

Insert the wooden toe-boards in the

toe-board holder on all the 4 sides.

12ASSEMBLY

Toeboard Assembly Details

Fix the claw of the Toeboard TB on the

Rungs facing each other as shown in the

figure.

Then insert the Side Toeboard and the End

Toeboard in the respective toeboard slots

as shown in the figure.

Clamping Instructions

Always ensure the Spring Clips are in the

lock position after inserting the upper

frame in the Spigot. To insert, unlock the

Spring Clip.

Side

ToeBoard

End

ToeBoard

Spring Clip

Spigot

Unlock Position Lock Position

13COMPONENTS

FS20135

Span Frame

FS10135

Span Frame

BT200/250

ToeBoard Set

FL10135

Ladder Frame

FL20135

Ladder Frame

CW150/200, JA500

Castor Wheel, Adjustable Jack

PF200/250

Fixed Platform

PT200/250

Trapdoor Platform

ST200/300/450/600

Stabilizer

BD200/250, BH200/250

Diagonal Brace, Horizontal Brace

14COMPONENTS

AGR200/250

Advanced Guard Rail

Stabilizers are to be used, when specified, to guarantee

the structural stability of the tower.

Fig. 01Fig. 01

Fig. 02Fig. 02 Fig. 03Fig. 03

Fig. 04Fig. 04

Lightly tighten the upper clamp of the stabilizer on each corner vertical posts at a height where

the foot is touching the ground. Position the clamp of the lower arm such that the lower arm

is as horizontal as possible.

Fig. 01Fig. 01

Position the stabilizers so that the footpads are approximately equidistant from each other.

Adjust the stabilizers and reposition the clamps as required to make firm contact with the

ground. When in correct position, tighten all the clamps firmly.

Fig. 02Fig. 02

Fig. 03Fig. 03

To position a tower in the corner of walls, remove the corner stabilizer and place the two towards

the wall, parallel to the wall. The middle one should be placed as shown in the graphic Fig.04

Fig. 04Fig. 04

To position a tower against a wall, do not remove the stabilizer, move parallel to the wall.

15STABILIZERS

Moving the Tower

To move the tower to a new position, first prepare the

tower.

Check that the wind speed does not exceed 17 mph.

Ensure the tower is empty (material and personnel).

Check the overhead obstructions including electrical cables.

Raise the stabilizer feet (only enough to clear obstructions, maximum 25mm).

Taking care to ensure tower stability is maintained, release the castor brakes.

Once positioned, prepare the tower for use.

Check that the tower is vertical.

Reapply the castor brakes.

Check and adjust as necessary to ensure all castors and stabilizers are in firm contact with

the ground.

Carefully move the tower by manually applying force at the base. Do Not Use mechanical

means to move the tower.

Comply To

Type Approval

Certified and independently tested for use.

Compliant to AGR Assembly process.

Safe working load on the platform is 250kgs/Sq Mtr, evenly distributed.

Maximum permissible distributed load on the tower 750 Kgs.

The scaffold towers referred to herein have been tested by

16STABILIZERS

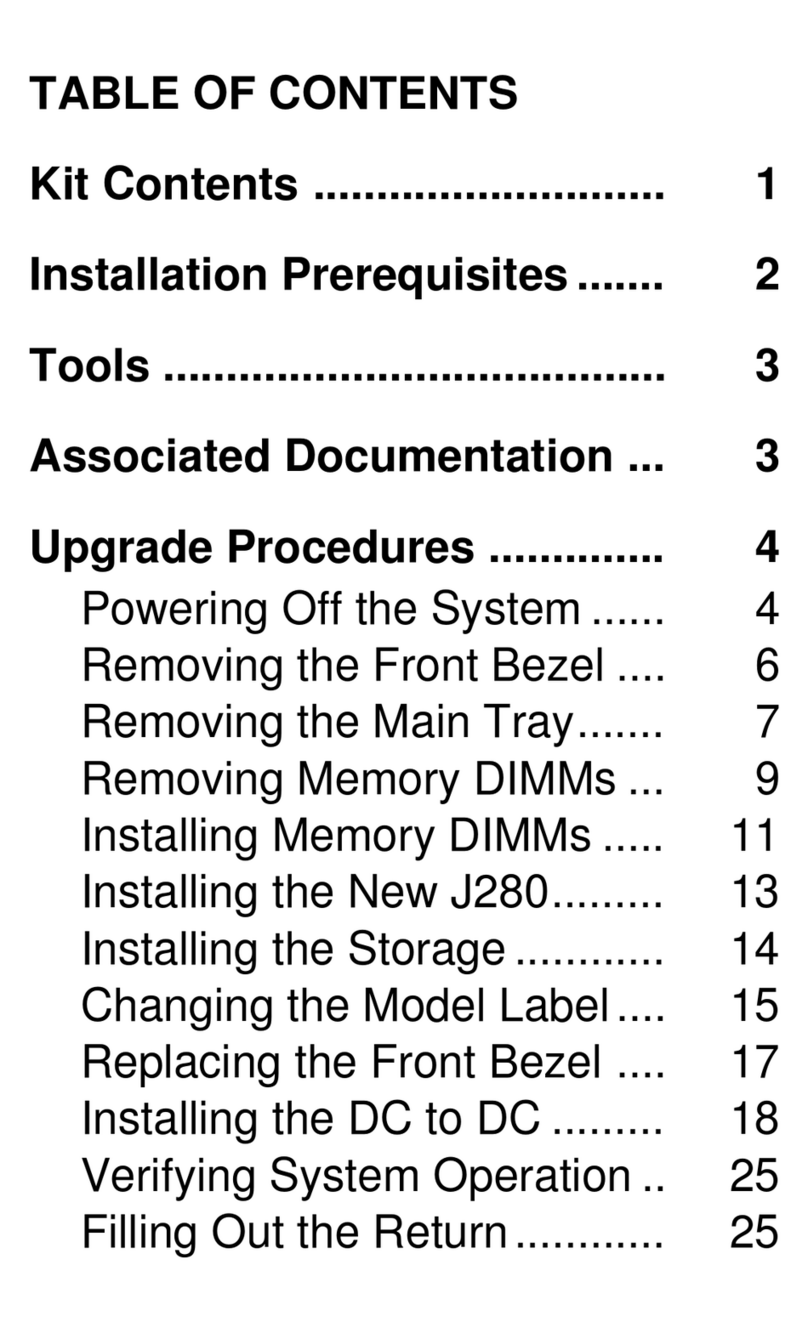

MADW SERIES TABLE confirming to EN1004

ALUMINIUM DOUBLE WIDTH TOWER - AGR Method

17COMPONENTS TABLE

MADW

Components Code Specs

220 320 420 520 620 720 820 920 1020 1120 1220

Tower Height in Mtrs 2.2 3.2 4.3 5.3 6.3 7.3 8.3 9.3 10.3 11.3 12.3

3.2 4.2 5.3 6.3 7.3 8.3 9.3 10.3 11.3 12.3 13.3

1.2 2.2 3.3 4.3 5.3 6.3 7.3 8.3 9.3 10.3 11.3

79/86

1 5

1

0

0

106/111 140/152 157/168 188/204 207/222 238/259 258/277 288/314 303/326 333/363

in Mtrs

in Mtrs

in Kgs

2.0 MtrsFL20135

FS20135

FL10135

FS10135

2.0 Mtrs

1.0 Mtrs

1.0 Mtrs

Working Height

Platform Height

Weight

Ladder Frame

Span Frame

Ladder Frame Mini

Span Frame Mini

4

0

4

0

2

0

0

0

1

1

1

1

1

1

4

0

4

2

2

0

0

0

1

1

11

2

2

0

0

0

4

4

2

4

4

0

0

2

1

1

2

2

1

1

0

4

4

2

4

4

0

0

2

1

1

3

3

0

0

0

4

4

2

6

4

0

0

3

1

1

3

3

1

1

0

4

4

2

6

0

4

0

3

1

1

4

4

0

0

0

4

4

2

8

0

4

0

4

1

1

4

4

1

1

0

4

4

2

8

0

0

4

4

1

1

5

0

0

0

4

4

2

10

0

0

4

5

1

1

5

5

1

1

0

4

4

2

10

0

0

4

5

1

1

6

6

0

0

0

4

4

2

12

0

0

4

6

1

1

CW150

CW200

JA500

ST300

ST450

ST600

BH200/250

BT200/250

BD200/250

PT200/250

PF200/250

2.0 Mtrs

2.2 Mtrs

3.0 Mtrs

4.5 Mtrs

6.0 Mtrs

2.0 Mtrs

2.0 Mtrs

Set

0.5 Mtrs

6 Inches

8 Inches

Caster Wheel

Caster Wheel

Adjustable Jack

Horizontal Braces

Diagonal Braces

Stabilizer

4 4 0 0 0 0 0 0 0 0 0

ST200 2.0 Mtrs

Stabilizer

Stabilizer

Stabilizer

Platform Trapdoor

Platform Fixed

Toe Board

2.0 Mtrs

AGR Frame AGR200/250 24 6 8 10

24 6 6 8 10

EN1004-1 Certification by TUV India

18

https://twitter.com/affixscaffoldinhttps://twitter.com/affixscaffoldin

https://www.facebook.com/affixscaffoldinhttps://www.facebook.com/affixscaffoldin

https://www.linkedin.com/company/affix-scaffolding-llc/https://www.linkedin.com/company/affix-scaffolding-llc/

https://qrco.de/bcPyx6

To Check Assembly Video

SCAN ME

PO Box No. 201633 Doha, Qatar

Tel +974 4416 1483 Mobile +974 5529 9893

Mobile +974 3030 0685

Website: www.affixscaffolding.com

This manual suits for next models

11

Table of contents