Installation procedures for ICAR certified meters

Afiflo 2000

Version July 2018

Installation manula for Afiflo 2000 mik meter - Page 2 of 33.

Table of Contents

1Introduction................................................................................................................................ 3

2The control panel....................................................................................................................... 3

3Chapter 1: Overview .................................................................................................................. 4

3.1 The Milk Meter Body ............................................................................................................ 5

3.2 The Control Panel ................................................................................................................ 6

3.3 The Controller ...................................................................................................................... 7

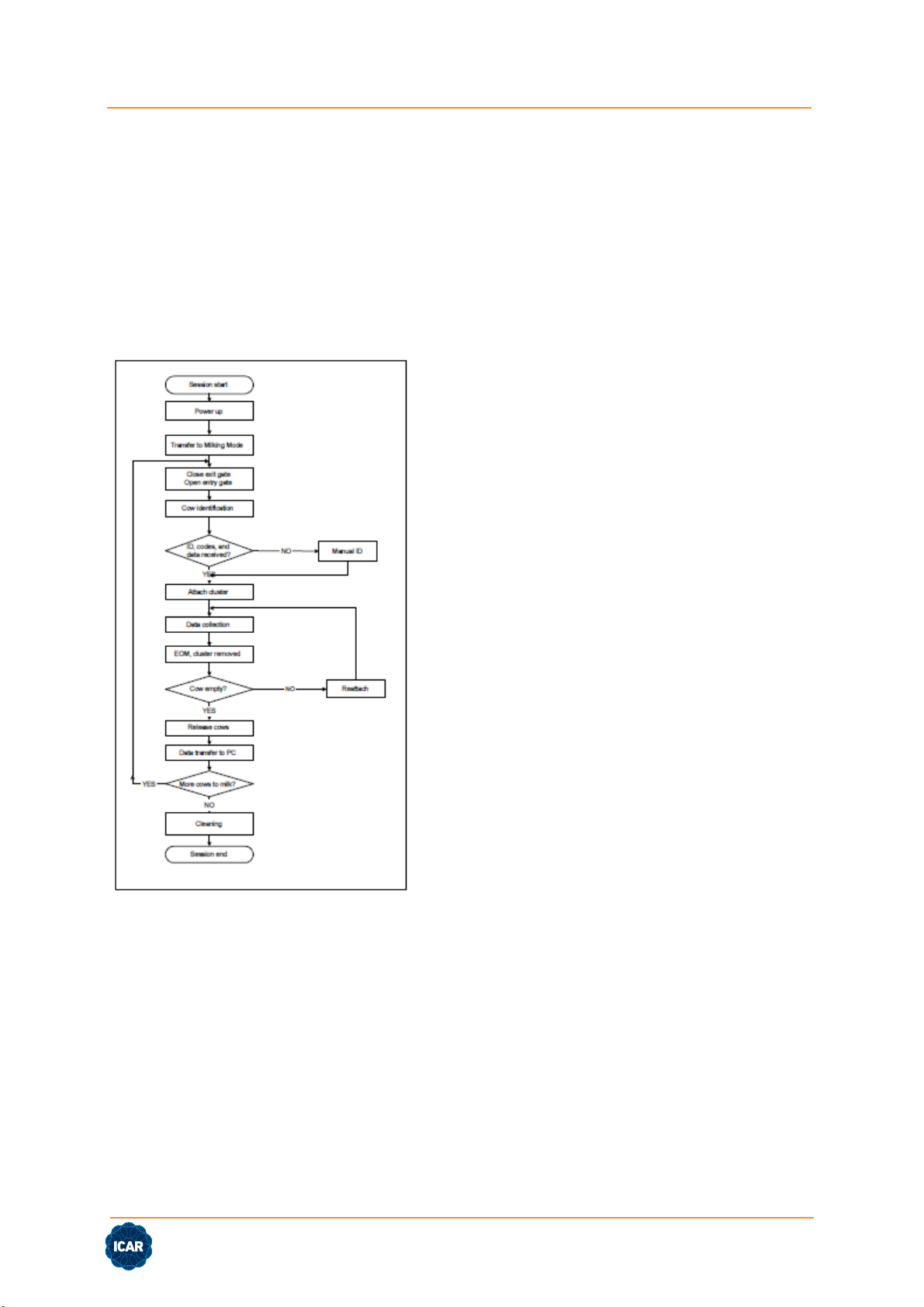

4Chapter 2: Operation ................................................................................................................. 8

4.1 The Start-up Sequence........................................................................................................ 9

4.2 The Primary Fields ..............................................................................................................9

4.3 Cow Number Field ............................................................................................................... 9

4.4 The operation keys ............................................................................................................ 11

4.5 Parlor alarms ..................................................................................................................... 13

5Chapter 3. Monitoring data and sending messages.............................................................14

5.1 Sending messages............................................................................................................. 17

6Chapter 4. Special features and operations .........................................................................19

6.1 Controlling entry and exit gates....................................................................................... 20

6.2 Data storage ....................................................................................................................... 20

6.3 Pulsation and strip field .................................................................................................... 20

7Chapter 5. Cleaning route .......................................................................................................21

7.1 Recommendations ............................................................................................................. 21

7.2 General instructions .......................................................................................................... 22

7.3 Cleaning cycle .................................................................................................................... 23

7.4 Operation in cleaning mode.............................................................................................. 24

8Chapter 6. Milk meter body and fat sampler ........................................................................25

8.1 Silicone and rubber component replacement ................................................................ 27

8.2 The fat sampler.................................................................................................................. 28

9Chapter 7. Troubleshooting....................................................................................................29

10 Appendix. Milk meter software version 19.01 .....................................................................30

10.1 Toggling cluster level........................................................................................................ 31