2

OPERATING INSTRUCTIONS AT A GLANCE

Before Operating Pump:

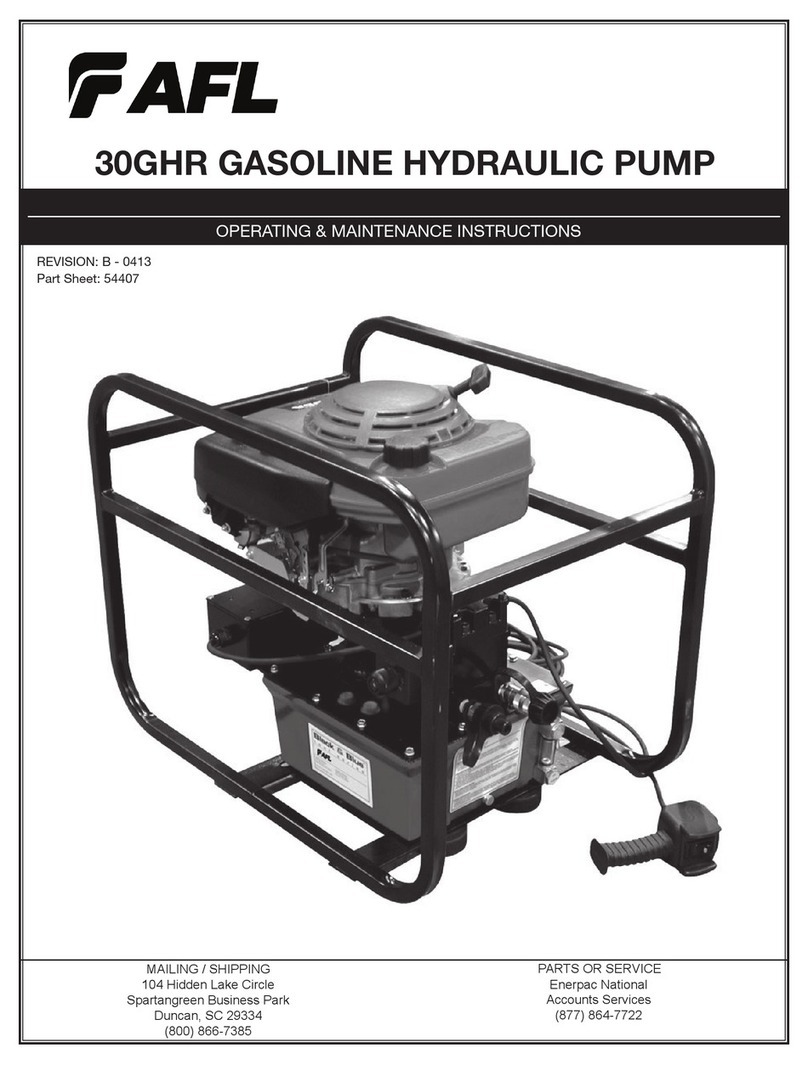

1. Use only cylinders , hoses and equipment rated at 10,000 psi.

2. Make sure all hose and tting connections are tight and secure. Hoses cannot be kinked or twisted.

3. Oil level should be 1”from the top of the reservoir plate, with tool retracted and motor o.

4. Never operate the pump in advance at 10,000 psi without tool movement for more than 1 minute.

Continuing to operate the pump without tool movement will overheat the oil.

After Completing the Job:

1. Before disconnecting hoses, ttings, etc, be sure the tool is retracted and unloaded, then unplug the power cord.

2. Store the pump in a clean, dry area.

Periodic Maintenance:

1. Completely change the hydraulic oil and clean the oil lter screen and magnet (located in the reservoir) twice a year.

(Use SIMPLEX oil only - Part #A01). Change the oil more frequently when used in extremely dusty areas or when the oil has

been overheated. Using oil other than the SIMPLEX brand, may void the pump warranty.

SECTION I

SAFETY

1-1.

Working Pressure

The pump’s maximum working pressure is 10,000 psi (700 kg/cm2). Make sure that all hydraulic equipment, hoses , etc. used with

this pump are rated at 10,000 psi operating pressure.

1-2.

Hydraulic Connections

Never disconnect or connect any hydraulic hoses or ttings without rst unloading the tool. Unplug the electrical cord of the

pump and open all hydraulic controls to ensure that the system has been depressurized. If the system includes a gauge, double

check the gauge ensure pressure has been released.

When making connections with quick disconnect couplings , make sure the couplings are fully engaged. Threaded connections

such as ttings , gauges , etc. mus t be securely tightened and leak free.

CAUTION: Loose or improperly threaded ttings can be potentially dangerous if pressurized, however, severe over

tightening can cause premature thread failure. Fittings need to be tightened secure & leak free. Never hold or stand

directly in line with any hydraulic connections while pressurizing. Never grab, touch or in any way come in contact with a

hydraulic pressure leak. Escaping oil can penetrate the skin and a serious injury can result.

Do not subject the hose to potential hazard such as sharp surfaces , extreme heat or heavy impact. Do not allow the hose to kink &

twist. Inspect each hose for wear before each use.