801-B00 Page 7/24

MOTOR DRIVEN PUMPS - INSTALLATION AND OPERATION

7) Connect and set the pressure switch to a set-point

approx. 10-30 psi above the system process

pressure. Ensure the switch is set at a pressure

between the Nitrogen set point and the max

anticipated discharge pressure. This pressure

switch should be wired to a panel or warning light or

alarm to prevent a decrease in barrier fluid pressure

below the pressure of the process fluid. This would

prevent process fluid from ever escaping into the

intra-seal cavity and potentially to atmosphere.

Dual Seal designs require sensing

devices to monitor seal performance

and detect leakage. Failure to properly

install sensing devices may result in

product leakage.

Hazardous or toxic

fluids can cause

serious injury.

8) A sensing device is required to ensure that

process fluid does not escape pump in case of

seal failure. If the seal fails, the barrier fluid

pressure and the barrier fluid level in the SPA

will drop. A pressure switch or a liquid level

switch may be used to sense these conditions

and the system should then be shut down to

prevent product leakage to atmosphere.

9) For the Plan 52 Seal only: Ensure the SPA tank is

vented to atmosphere through an orifice. The vapor

space of the Seal Pot should be open atmospheric

pressure during operation. The tank should be kept

below discharge pressure of the pump, at all times.

This includes during periods of non-operation. If the

SPA tank pressure exceeds discharge pressure, the

outer seal can open and may cause contamination of

barrier oil into system. The seal may not reseat

once pressure is dropped.

10) Close the SPA tank vent and slowly allow the pump

to fill with the pumping fluid while monitoring the SPA

tank pressure and barrier oil level (if possible). If the

barrier oil pressure or level increases, there is a seal

leak and the pump should be removed from service

and replaced.

11) Connect and set a pressure switch to a set-point of

approx. 10 psig. This pressure switch should be

wired to a panel or warning light or alarm to prevent

the barrier pressure from exceeding the process

pressure. This would prevent barrier fluid leaking into

the system or process fluid from contaminating the

barrier oil due to the outer seal opening.

Note: A suitable orifice should be installed inline.

This will allow a leak to be detected by

increasing the SPA tank pressure. Under normal

operation vapor emissions should be properly

contained and disposed (e.g. flared off).

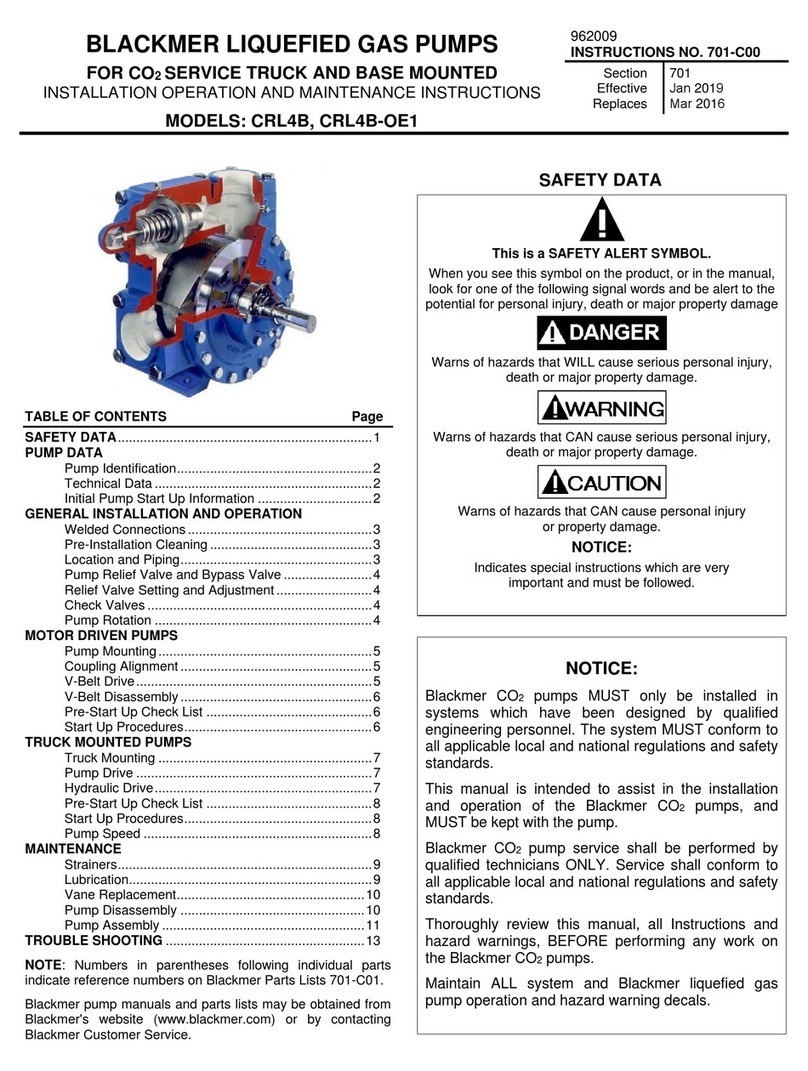

Figure 7 Plan 52 Pressure Switch Installation

Dual Seal designs require sensing

devices to monitor seal performance

and detect leakage. Failure to properly

install sensing devices may result in

product leakage.

Hazardous or toxic

fluids can cause

serious injury.

12) A sensing device is required to ensure that

process fluid does not escape pump in case of

seal failure. If the seal fails, the barrier fluid

pressure and the barrier fluid level in the SPA

will increase. A pressure switch or a liquid level

switch must be used to sense these conditions

and the system should then be shut down to

prevent product leakage to atmosphere.

INSTALLATION AND CONNECTION:

13) The following is a checklist for completion prior to

operation of the pump:

All plumbing connected, 1 barrier fluid supply line

to each side of pump and one return line to each

side of pump.

All air has been bled out of system.

Bleed valve shut. Seal supply and Seal return

valves open.

Pressure of barrier fluid system is 30 – 50 psi

above process pressure for the Plan 53 Seal or at 0

psig for the Plan 52 Seal.

Once pressurized, the nitrogen pressure supply to

the SPA is shut off for the Plan 53.

SPA pressure is constant.

There are no barrier fluid leaks in the

tubing/piping/hoses.

Open pump inlet valve and ensure no process

fluid leakage.

Open pump discharge valve

During operation, pressure in the barrier fluid

system (SPA) stays constant.

Having completed these steps and the checklist above, the

pump should be ready for operation.