4

DIAGNOSTIC FUNCTIONALITY and SENSOR TESTING FUNCTIONS

The HT101S Function Switch is located in the lower, center position of

the Tester. When dialed to any position except “OFF” the meter

functions are all available.

Set to MONITOR to use the Tester as a standard meter or to make tests

of the complete connection of the Display to the Sensor being tested.

When connected using the “In-Line” Tester TEE Harness, there are 3

possible connections made available for tests. A 3 wire sensor will have

a ground, a positive supply voltage and a signal line. The HT101S makes

these connections available for testing with Test Jacks and any voltages

present will be displayed by the associated LEDs.

Test Jacks and LEDs are colorized to indicate:

RED = Supply Voltage from Display

Yellow = Signal

Two wire sensors won’t have a wire for power. These might include magnetic sensors and switches.

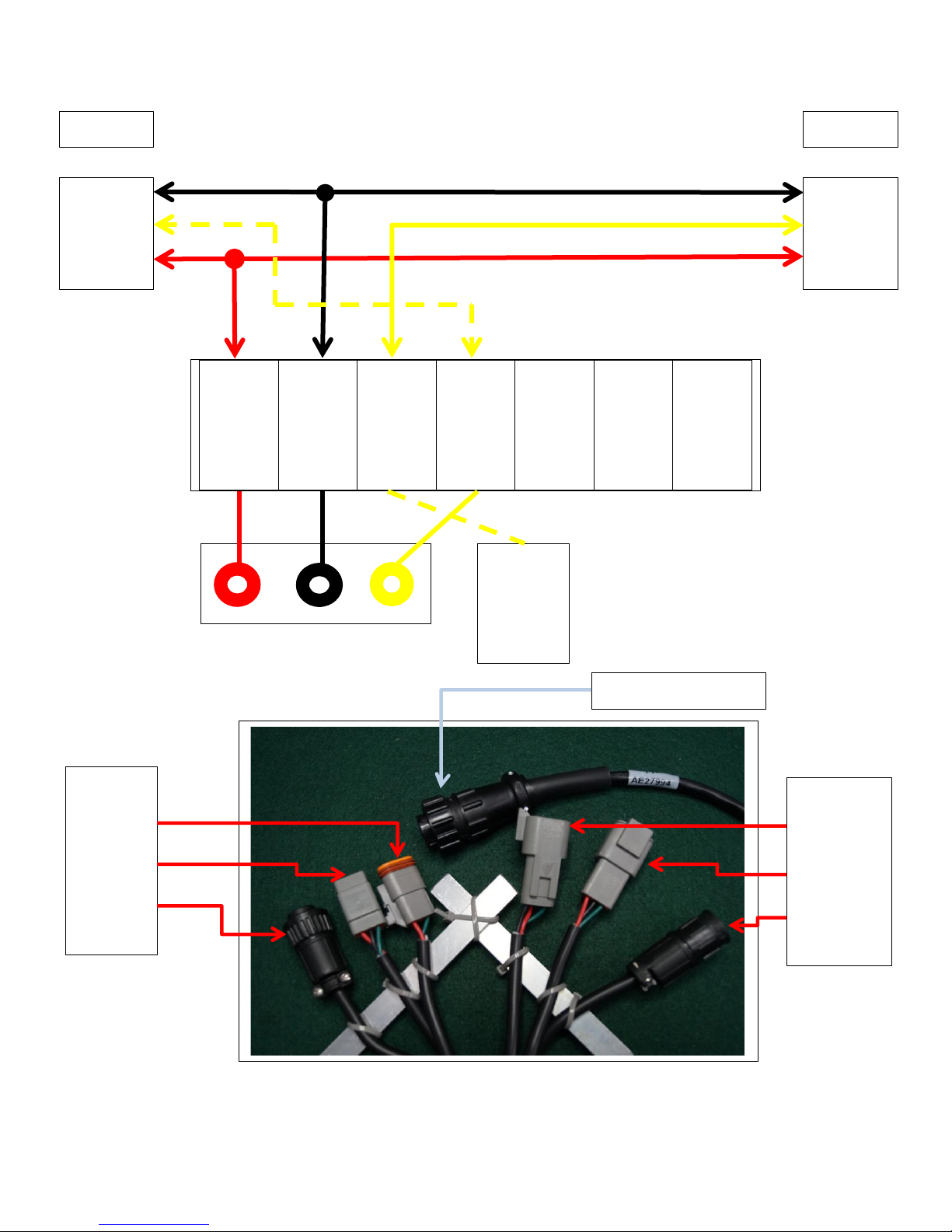

When dialed to “DIGITAL SIMULATE” two test functions are made available depending on the type of connecting harness

being used.

When using the In-Line harness, DIGITAL SIMULATE allows the HT101S to send a continual Test Signal back to the

Display. These are digital pulses where the frequency of the generated test signal is controlled by the “SET DIGITAL”

control. When fully counterclockwise the signal is at about 30 Hz or 30 pulses per second. Turning the control clockwise

will increase the frequency to 350 Hz or so. This is a sure way to locate cable trouble from the sensor to the display while

at the same time verifying the display is programmed to receive these digital signals.

When the Stand-Alone harness is used, DIGITAL SIMULATE is used to check the sensor, independent from the display.

The HT101S provides the Supply Voltage and the Signal Generated is available for tests at the YELLOW test jack. You’ll

see the Yellow LED blink as the pulses are generated and the Frequency can

be read by connecting the Meter to the Yellow and Black test jacks.

SET ANALOG allows the same type of tests to be performed but are used

with Analog Sensors.

When the In-Line harness is connected you can monitor the Supply Voltage

and the Generated Signal from the display to the sensor.

The Stand-Alone Harness allows for testing of the sensor independent from

the Display. The HT101S provides the Supply Voltage and Ground and the

generated signal is made available for test at the YELLOW test jack.