GENERAL NOTE

4

NOTE: THESE I STALLATIO I STRUCTIO S SHOULD BE LEFT WITH THE APPLIA CE

A D THE USER TO RETAI FOR FUTURE REFERE CE.

Before installation of an AGA can be made, the site is inspected for suitability by an authorized

AGA distributor and corrected where necessary to conform with local or regional electrical codes.

DELIVERY REQUIREMENT

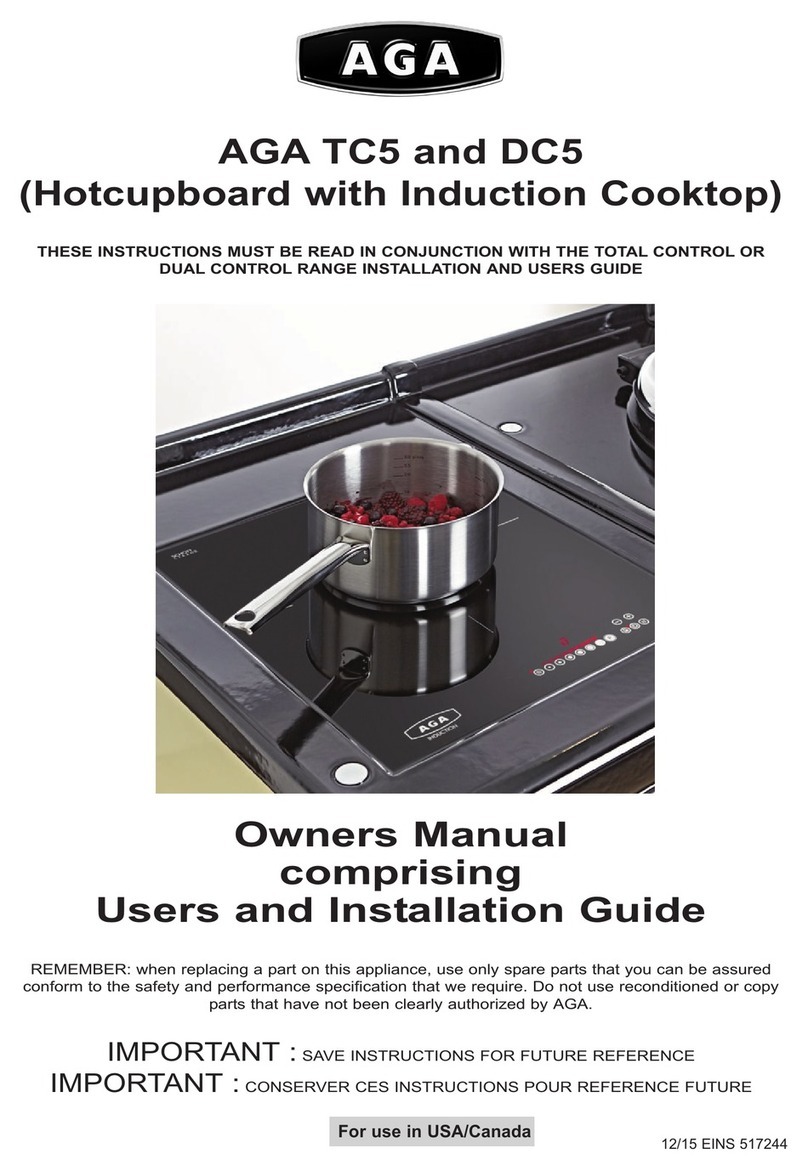

The AGA TC3 arrives on 1 pallet.

The AGA TC5 (Hotcupboard) arrives on 2 pallets.

There must be access to the kitchen to manipulate a foot print of 39 9/16” (1005mm) x 29 1/8”

(740mm). A wooden template (skate with castor wheels) of dimensions 39 9/16” (1005mm) x

29 1/8” 740mm could be used to check if the AGA Total Control fully built appliance is able to fit

through the property grounds and doors into its installation position in the kitchen. It must also

be considered that the height of the appliance is 37 6/8” (960mm) off pallet and 43 2/8”

(1100mm) on the pallet, so high level obstacles/restrictions must not be overlooked.

If this skate/template can be manipulated through the property grounds and doors

into position, then the AGA Total Control can be installed as intended with no re-work.

GENERAL IN TALLATION REQUIREMENT

The installation of the range must be in accordance with the relevant requirements of the local

Wiring and Building Regulations. It should be in accordance also with any relevant requirements

of the local or stated codes.

In your own interest and that of safety to comply with the law, all appliances should be installed

by an authorized AGA distributor in accordance with the relevant regulations.

USA

Model umber AGA TC3

FCC ID: A2M-AGA-TC3

FCC ID: A2M-AGA-TC3TEK

This device complies with part 15 of the

FCC Rules. Operation is subject to

the following two conditions:

(1) This device may not cause harmful

interference, and (2) this device must

accept any interference received,

including interference that may cause

undesired operation.

CA ADA

Model umber AGA TC3

IC: 10181A-AGATC3TEK

Model umber AE4M280526

IC: 10181A-AGATC3

This device complies with Industry Canada

licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this

device may not cause interference, and (2)

this device must accept any interference,

including interference that may cause

undesired operation of the device.

CAUTION:

THI UNIT I HEAVY, PROPER EQUIPMENT AND ADEQUATE

MANPOWER MU T BE U ED IN MOVING THE RANGE TO

AVOID DAMAGE TO THE UNIT OR THE FLOOR