INSTALLATION SEQUENCE AND PROCEDURE

Loose Items

On unpacking the hob unit, check that the following items are included before discarding

packaging:

1. Installation Instructions 12. Four (M5 screws)

2. Users Instructions 13. Two, flame spreaders/burner cap assemblies

3. Servicing Instructions (one for each burner size)

4. Hob chassis (fitted with burner, 14. Pan support

bowls, taps and mains lead 15. Two, control knobs

5. Four, burner fixing disc fitting 16. Two, knob spacer washers

screws (M3) 17. Blanking plate

6. Hob, top surface plate (ceramic 18. Two, No. 8 blanking plate screws

glass in frame with gasket) 19. Two, insulation pads

7. Two, stainless steel spring plates 20. Two, heat shield grommets

(one for each burner size) 21. One, top-hat gasket

8. Two, fixing discs (one for each 22. Copper fitting kit comprising: 2 metres of 8mm

burner size) pipe, 8mm x 8mm elbow, 15mm x 8mm straight

9. Two, fixing disc gaskets reducer

10. Two, 50mm M3 screws 23. 13 amp plug

11. One, 25mm M3 screw 24. Fitting kit - burner tray (AG4M211601)

This appliance is designed for use only with Aga four oven models and must be fitted in the top

casting above the hot cupboard.

1. Proceed with the main Aga build in accordance with normal practice. Build up to top-plate

level. (Refer to appropriate Installation Instructions).

2. Remove hotcupboard top plate by removing four chrome buttons and the four top plate

retaining screws. Remove warming plate from top plate casting, by carefully prising apart.

3. The hob unit must be installed by connection to rigid pipework of 8mm diameter.

Connection is made to the 8mm compression fitting (gas cock), located inside the rear left

hand side of the hob unit.

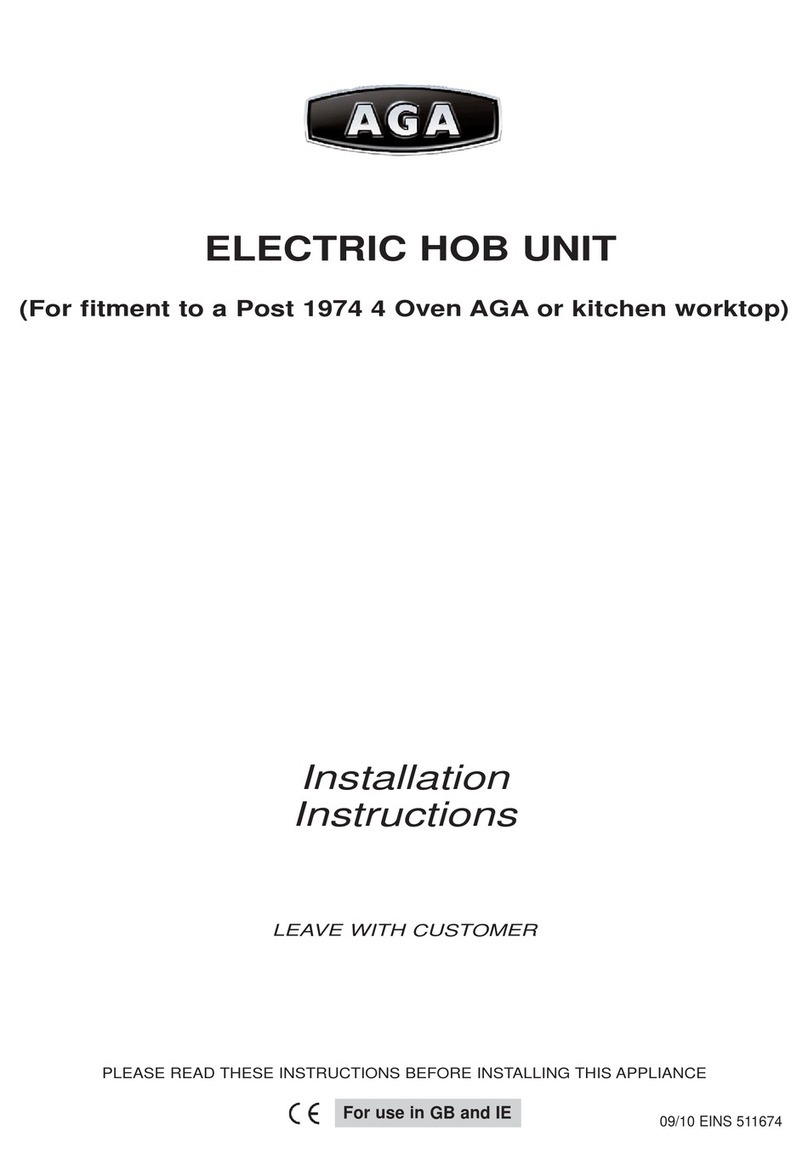

Prepare the gas supply as follows:-

(a) Decide whether the gas supply is to enter from the back or side of the hot cupboard.

(See Fig. 3). Knock out or drill appropriate holes. If the gas supply is to enter from the

side of the hotcupboard, use one of the spark knock-out holes in the side panel.

Pierce centre of top-hat grommet. Run supply pipe through grommet, then insert

grommet into side panel hole.

NOTE: On boiler models do not enter gas supply pipe through the same holes as flow

and return pipes. Also the supply pipe must be routed well away from the flow and

return pipes inside the hotcupboard.

6

340

140

65

95

48

17

210

A

AB

B

B

B

100

19

46 45

60

REAR

SIDE

A - GAS CONNECTION HOLES

B - ELECTRICAL CONNECTION HOLES

NOTE:

FOR ELECTRICAL CONNECTION HOLES

ONLY, GROMMETS ARE INSERTED INTO

THE INNER AND OUTER PANELS.

ALL HOLES 19mm DIAMETER

DESN 512063Fig. 3