2-2

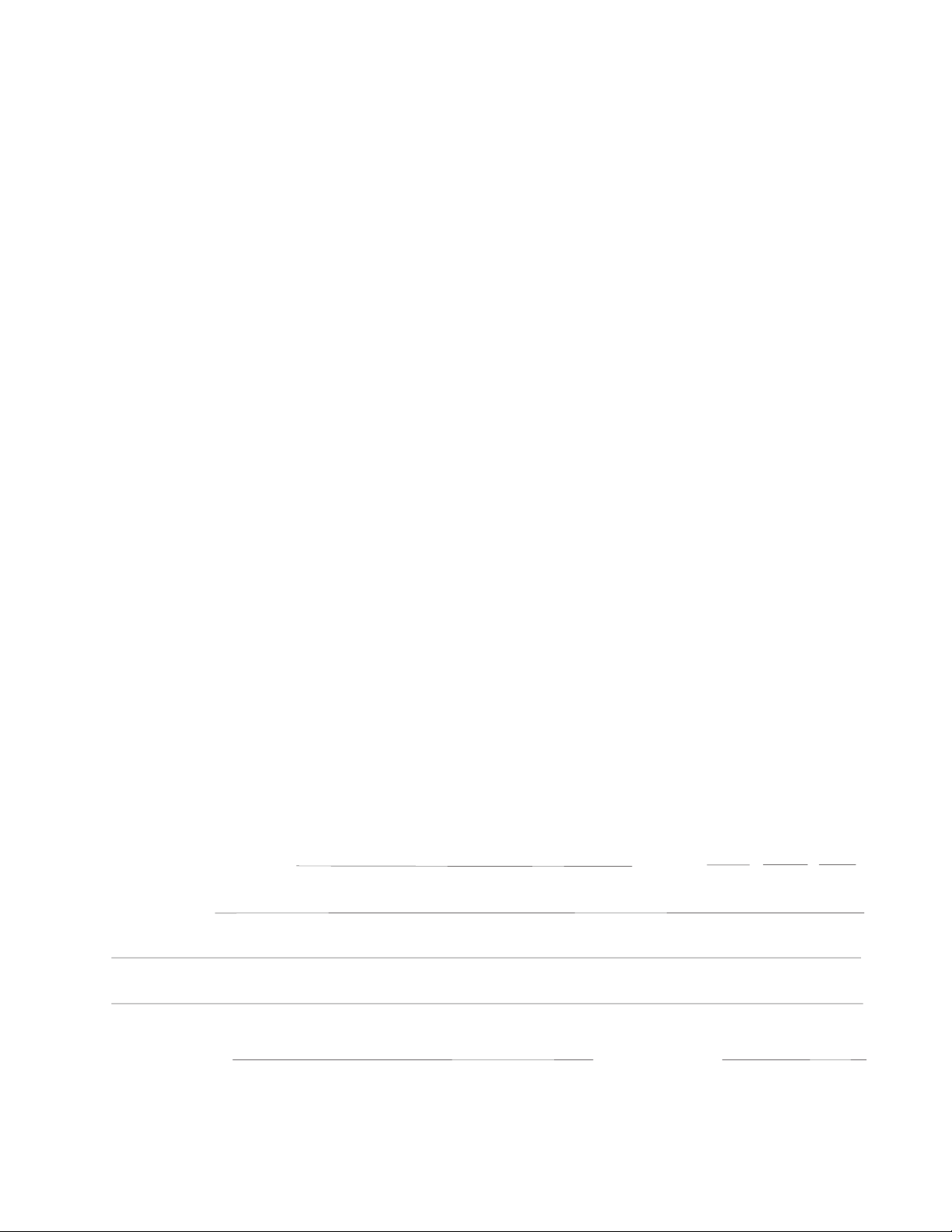

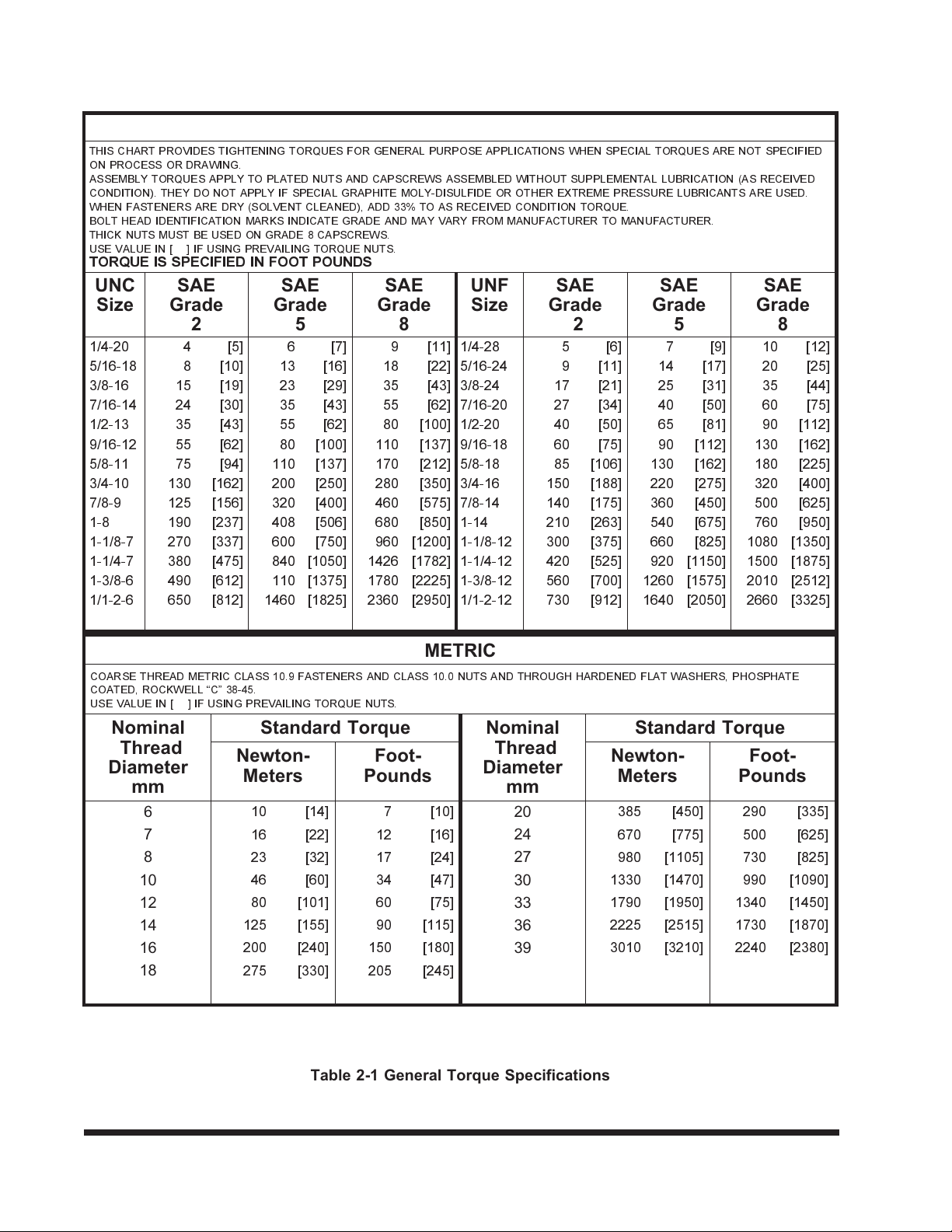

GENERAL TORQUE SPECIFICATIONS (REV. 4/97)

THIS CHART PROVIDES TIGHTENING TORQUES FOR GENERAL PURPOSE APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED

ON PROCESS OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED NUTS AND CAPSCREWS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATION (AS RECEIVED

CONDITION). THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

WHEN FASTENERS ARE DRY (SOLVENT CLEANED), ADD 33% TO AS RECEIVED CONDITION TORQUE.

BOLT HEAD IDENTIFICATION MARKS INDICATE GRADE AND MAY VARY FROM MANUFACTURER TO MANUFACTURER.

THICK NUTS MUST BE USED ON GRADE 8 CAPSCREWS.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

TORQUE IS SPECIFIED IN FOOT POUNDS

UNC

Size

SAE

Grade

2

SAE

Grade

5

SAE

Grade

8

UNF

Size

SAE

Grade

2

SAE

Grade

5

SAE

Grade

8

1/4-20 4 [5] 6 [7] 9 [11] 1/4-28 5 [6] 7 [9] 10 [12]

5/16-18 8 [10] 13 [16] 18 [22] 5/16-24 9 [11] 14 [17] 20 [25]

3/8-16 15 [19] 23 [29] 35 [43] 3/8-24 17 [21] 25 [31] 35 [44]

7/16-14 24 [30] 35 [43] 55 [62] 7/16-20 27 [34] 40 [50] 60 [75]

1/2-13 35 [43] 55 [62] 80 [100] 1/2-20 40 [50] 65 [81] 90 [112]

9/16-12 55 [62] 80 [100] 110 [137] 9/16-18 60 [75] 90 [112] 130 [162]

5/8-11 75 [94] 110 [137] 170 [212] 5/8-18 85 [106] 130 [162] 180 [225]

3/4-10 130 [162] 200 [250] 280 [350] 3/4-16 150 [188] 220 [275] 320 [400]

7/8-9 125 [156] 320 [400] 460 [575] 7/8-14 140 [175] 360 [450] 500 [625]

1-8 190 [237] 408 [506] 680 [850] 1-14 210 [263] 540 [675] 760 [950]

1-1/8-7 270 [337] 600 [750] 960 [1200] 1-1/8-12 300 [375] 660 [825] 1080 [1350]

1-1/4-7 380 [475] 840 [1050] 1426 [1782] 1-1/4-12 420 [525] 920 [1150] 1500 [1875]

1-3/8-6 490 [612] 110 [1375] 1780 [2225] 1-3/8-12 560 [700] 1260 [1575] 2010 [2512]

1/1-2-6 650 [812] 1460 [1825] 2360 [2950] 1/1-2-12 730 [912] 1640 [2050] 2660 [3325]

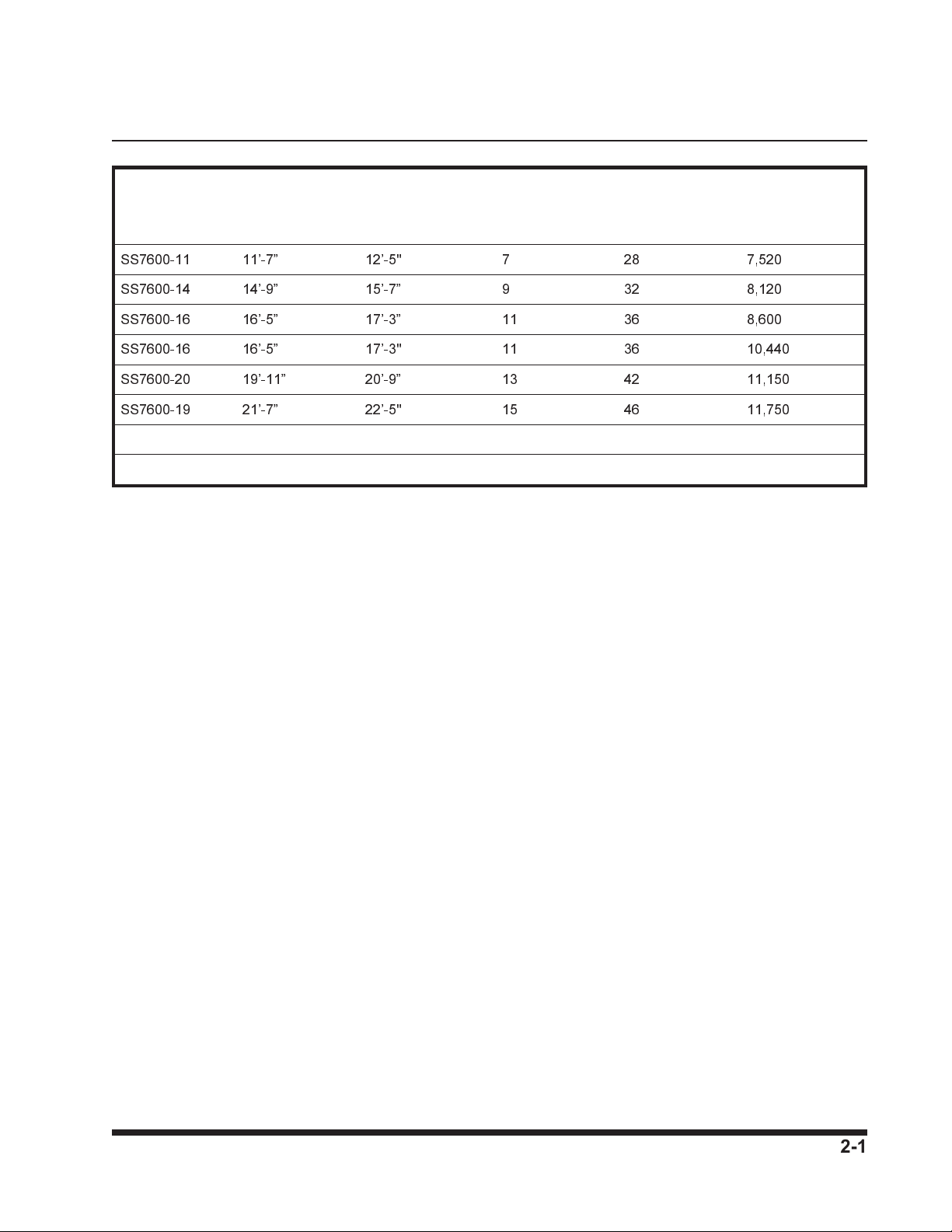

METRIC

COARSE THREAD METRIC CLASS 10.9 FASTENERS AND CLASS 10.0 NUTS AND THROUGH HARDENED FLAT WASHERS, PHOSPHATE

COATED, ROCKWELL C 38-45.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

Nominal

Thread

Diameter

mm

Standard Torque Nominal

Thread

Diameter

mm

Standard Torque

Newton-

Meters

Foot-

Pounds

Newton-

Meters

Foot-

Pounds

6

10 [14] 7 [10]

20

385 [450] 290 [335]

7

16 [22] 12 [16]

24

670 [775] 500 [625]

8

23 [32] 17 [24]

27

980 [1105] 730 [825]

10

46 [60] 34 [47]

30

1330 [1470] 990 [1090]

12

80 [101] 60 [75]

33

1790 [1950] 1340 [1450]

14

125 [155] 90 [115]

36

2225 [2515] 1730 [1870]

16

200 [240] 150 [180]

39

3010 [3210] 2240 [2380]

18

275 [330] 205 [245]

Table 2-1 General Torque Specifications