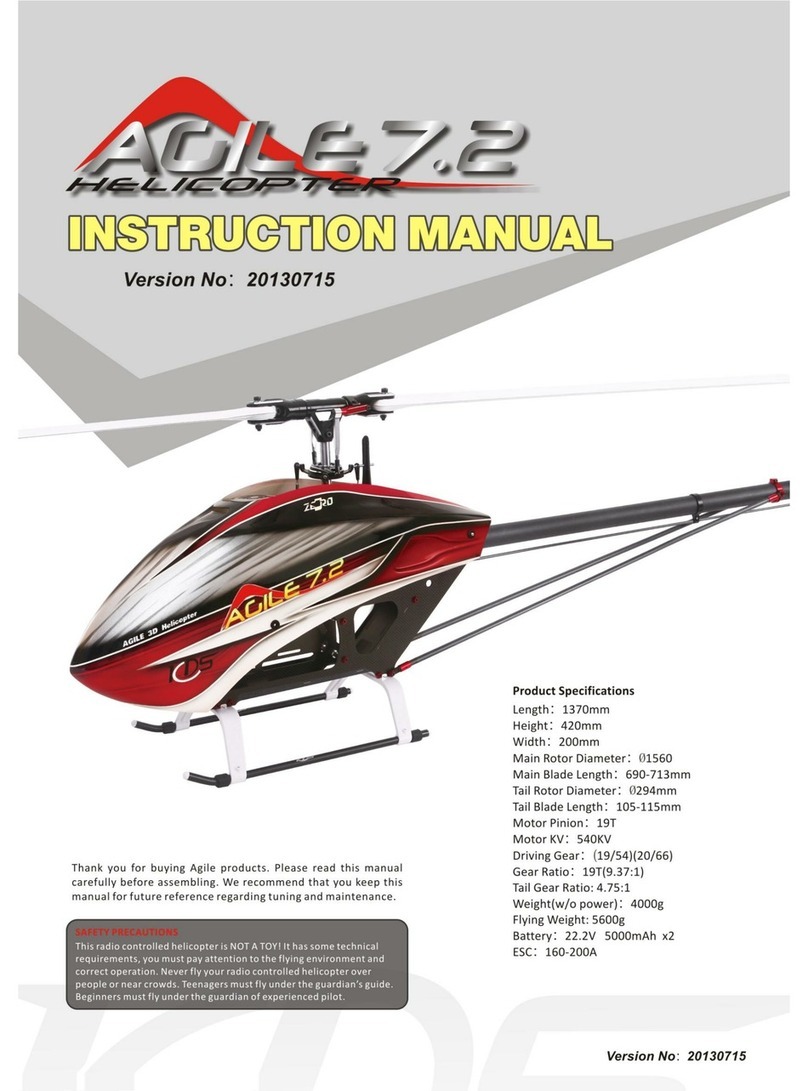

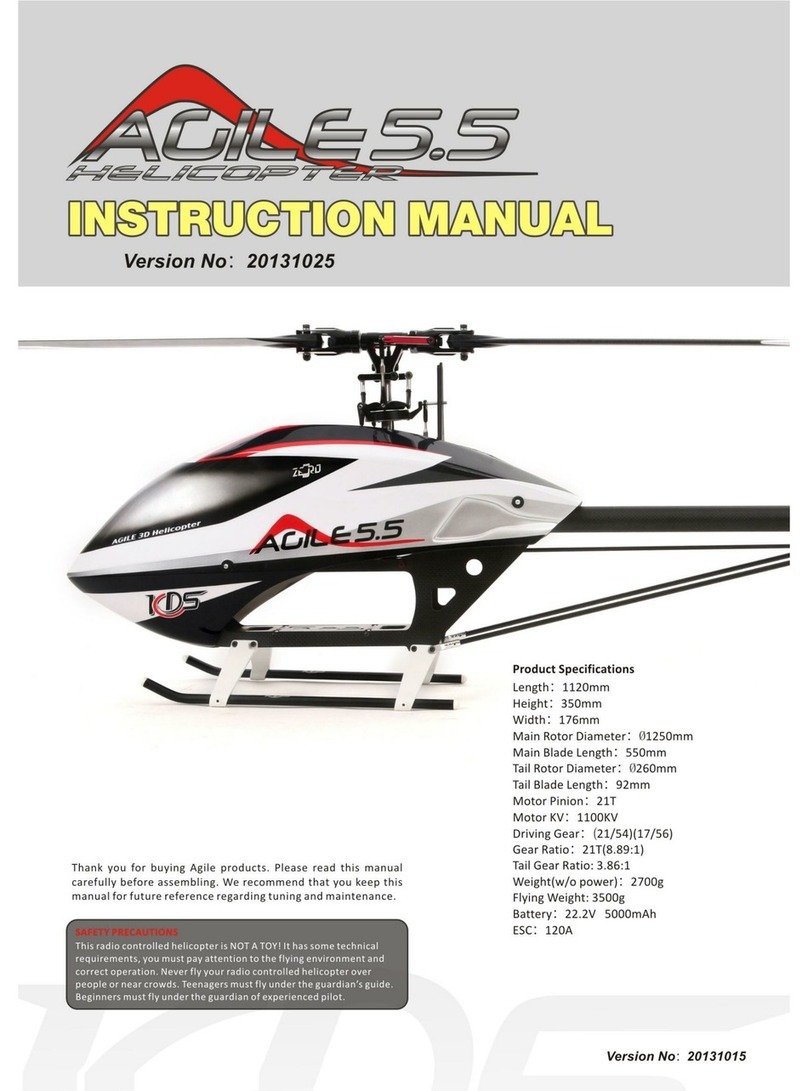

Congratulations on your purchase of the Agile 5.5 radio controlled helicopter kit. Agile 5.5 was designed in Europe by Eng. Gaziano

Roberto and is proudly manufactured by KDS Model. Our goal was to offer you something different with a minimum of parts, easy

maintenance, and outstanding flying performances.

It’s time to fly different!...

IMPO RTANT N OTE S

NOTE FOR AS SEMBLY

R/C helicopters, including the AGILE 5.5 are not toys. R/C helicopters utilize various high-tech products and technologies to provide

superior performance. Improper use of this product can result in serious injury or even death. Please read this manual carefully

before using and make sure to be conscious of your own personal safety and the safety of others and your environment when

operating all AGILE products. Agile 5.5, KDS Model, their affiliates and authorized distributors are not responsible for personal

injuries to the operators and others, and property damages that could occur from the assembly, maintenance or your use/misuse of

this product. Always respect the rules provided by your local remote control aircraft organization.

The following manual provide important instructions to correctly assemble the model. It is structured in a logical way, based on the

work done in previous step. If you change the order, it may result in additional or unnecessary steps. So we suggest you to read this

user manual very carefully to understand correctly the assembly procedure. Failure to do so may not only downgrade performances

but also increase the risk of danger. Apply thread lock as indicated, allow the threadlock to cure before mounting parts. It is

recommended to use threadlock on each bolt or screw that are engaged with metal parts.

LOCATE A N AP PROP RIATE LOC ATI ON

R/C helicopters fly at high speed, thus posing a certain degree of potential danger. Choose an

appropriate flying site consisting of flat, smooth ground, a clear open field, or a large open room, such

as gymnasium or warehouse without obstacles. Do not fly near buildings, high voltage cables, or trees

to ensure the safety of yourself, others and your model. Do not play your model in inclement weather,

such as rain, wind, snow or darkness.

OBTAIN TH E ASSIS TANCE OF A N EX PERIE NCED PI LOT

Before turning on your model and transmitter, check to make sure no one else is operating on the

same frequency. Frequency interference can cause your model, or other models to crash. The

guidance provided by an experienced pilot will be invaluable for the assembly, tuning, trimming, and

actual first flight(recommend you to practice with computer-based flight simulator).

1.INTRODUCTION

2.SAFETY NOTES

During the operation of the helicopter, the main rotor will be spinning at a high rate of speed. The

blades are capable of inflicting serious bodily injury and damage the environment. Be conscious of

your actions, and careful to keep your face, eyes, hands, and loose clothing away from the blades.

Always fly the model a safe distance from yourself and others, as well as surrounding objects. Never

take your eyes off the model or leave it unattended while it is turned on. lmmediately turn off the

model and transmitter when you have landed the model.

ALWAYS BE AW ARE OF TH E ROTATI NG BLAD ES

Agile Helicopter is a Trademark of Flight Research Rc Europe , Proudly made by KDS Model Shenzhen

Page 01

Enjoy the built and have a great time with you Agile 5.5!