CONTENTS

General Information .........................................................1-3

Specifications............................................................ 1

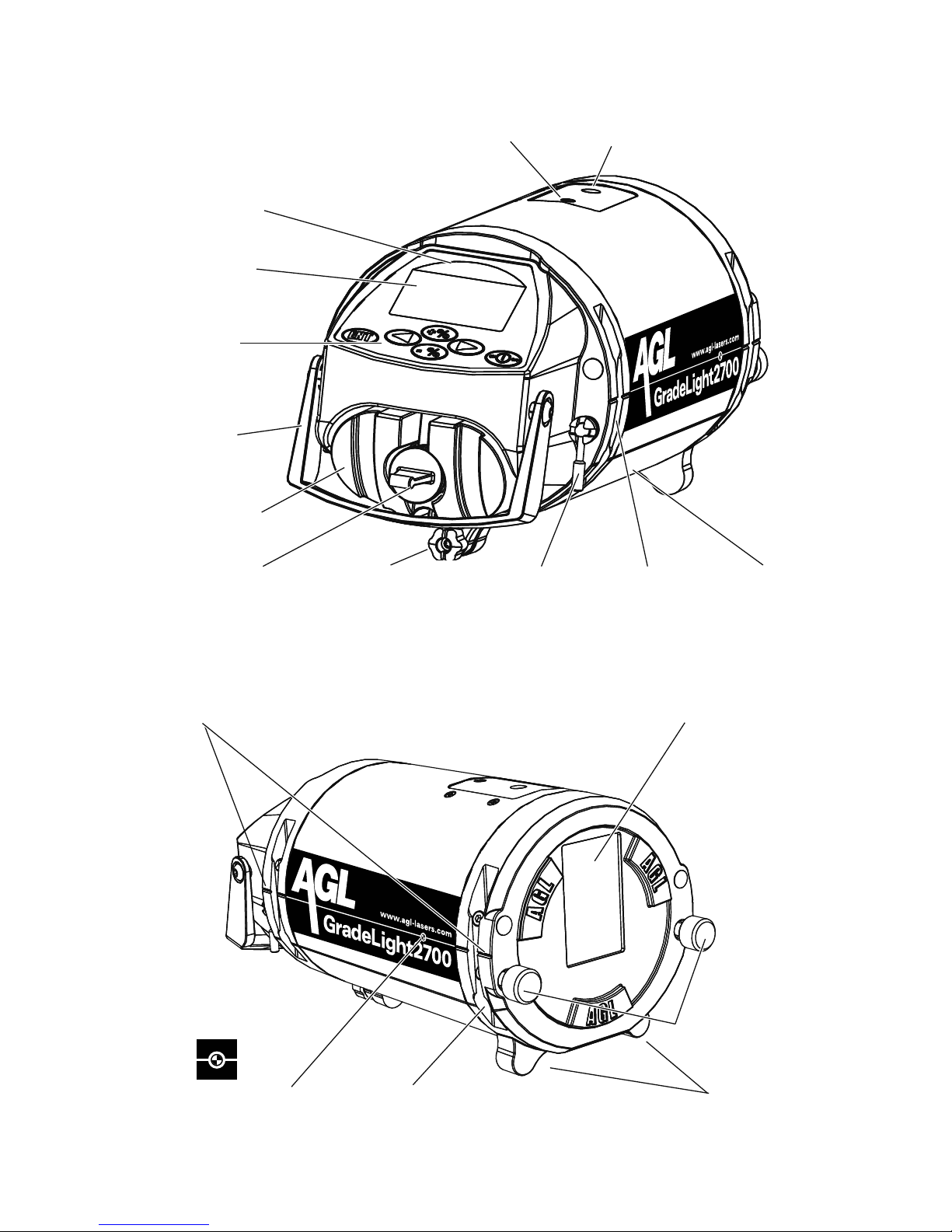

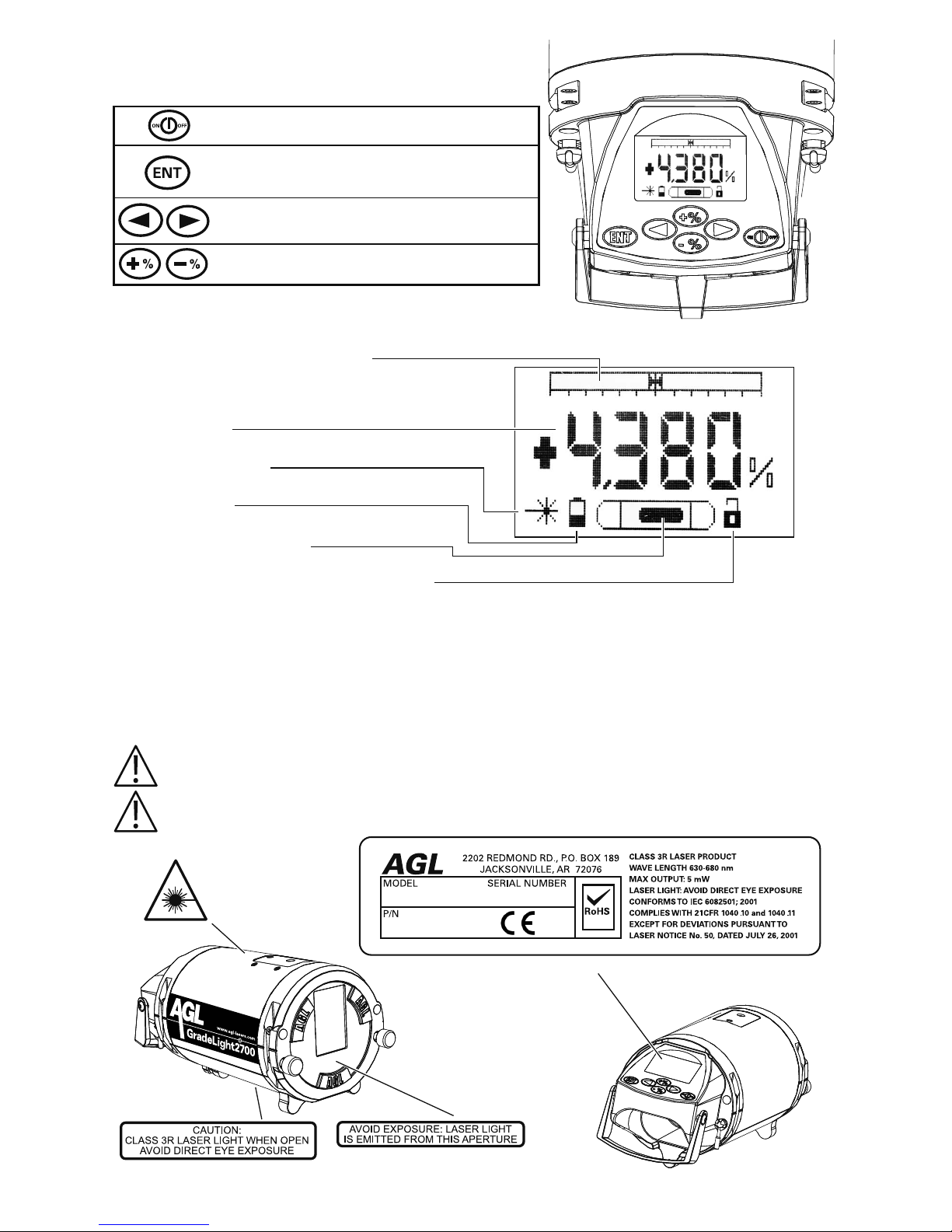

LaserOverview .........................................................2-3

Power ..................................................................... 4

Charging................................................................ 4

Removing the Battery Pack and Using Alkaline Batteries . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation ..................................................................5-9

Pipe Laying Overview ..................................................... 5

Laser Start-up............................................................ 5

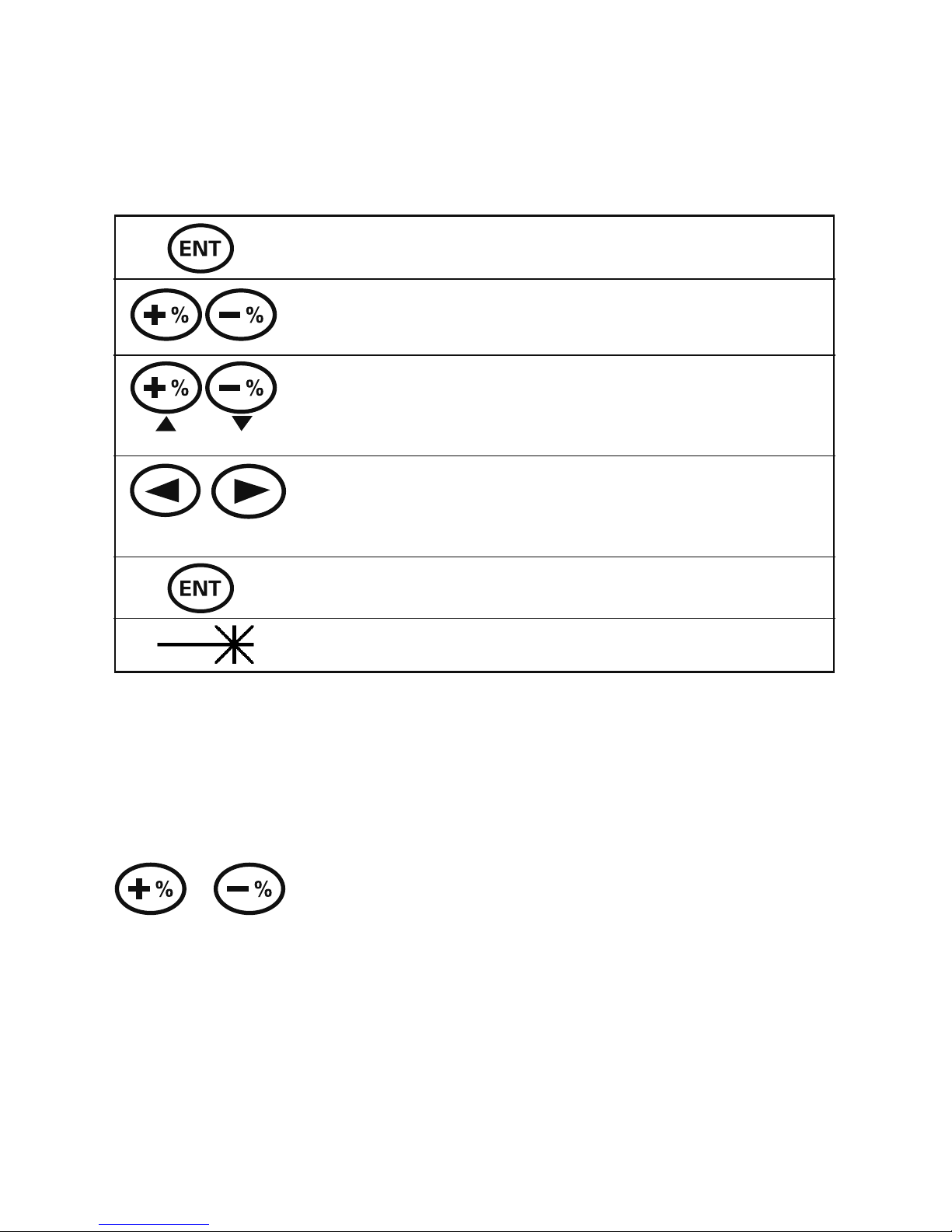

Entering Grade........................................................... 6

Automatic Reset to Zero Grade ........................................... 6

Remote Control and Line Adjustment (Azimuth) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replacing Batteries in Remote ............................................ 8

Adjustable Leg Set........................................................ 8

Using theTarget .......................................................... 9

BasicSet-upandOperation ................................................ 9

Applications ..............................................................10-16

ElevationTransfer ....................................................... 10

Using an Automatic Level .............................................. 10

Using the SpecialTransit and Rod Group .................................. 10

Alignment Methods.......................................................11

Manhole Mount withTransit..............................................11

SpecialTransitwithRodGroup.......................................... 12

Stringline Method ..................................................... 12

Plumb Bob Method .................................................... 12

Set-up Methods ......................................................... 13

Height Adjustable Legs................................................. 13

ManholeBaseSet-up................................................ 13

In-the-pipe Set-up ................................................... 13

InvertSet-up ....................................................... 14

OpenCutSet-up.................................................... 14

Trivet ............................................................... 15

ManholeBaseSet-up................................................ 15

RodandCrossbraceSystem ............................................ 15

Manhole Set-up..................................................... 15

Above Ground Set-up.................................................. 16

Menu Options ............................................................17-18

Information Available (including software version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Entering the Set-up Menu................................................. 17

ChangingtheServiceInterval ............................................. 18

DeletingCHECKCALReminder............................................ 18

UsingYour Company Information for the Start-up Screen . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting...........................................................19-20

DisplayScreenExplanations .............................................. 19

Using a Blower to Eliminate Refraction...................................... 20

Optional Equipment ......................................................... 20

Checking and Calibration ...................................................21-23

Safety, Care, and Handling .................................................... 24

Warranty ................................................................... 25

Important:

The operator of the GradeLight is expected to follow all operating instructions, periodically

check the accuracy of the unit, and make checks on control as the work progresses. The

manufacturer and its distributors assume no responsibility for improperly controlled work.