Table of Contents

Welcome ..............................................................................................................................................................4

Basic Concepts...................................................................................................................................................4

How the Program Calculates Grade .......................................................................................................................4

Units of Measure ...........................................................................................................................................................5

Glossary of Terms.........................................................................................................................................................5

The Main Working Screen .............................................................................................................................7

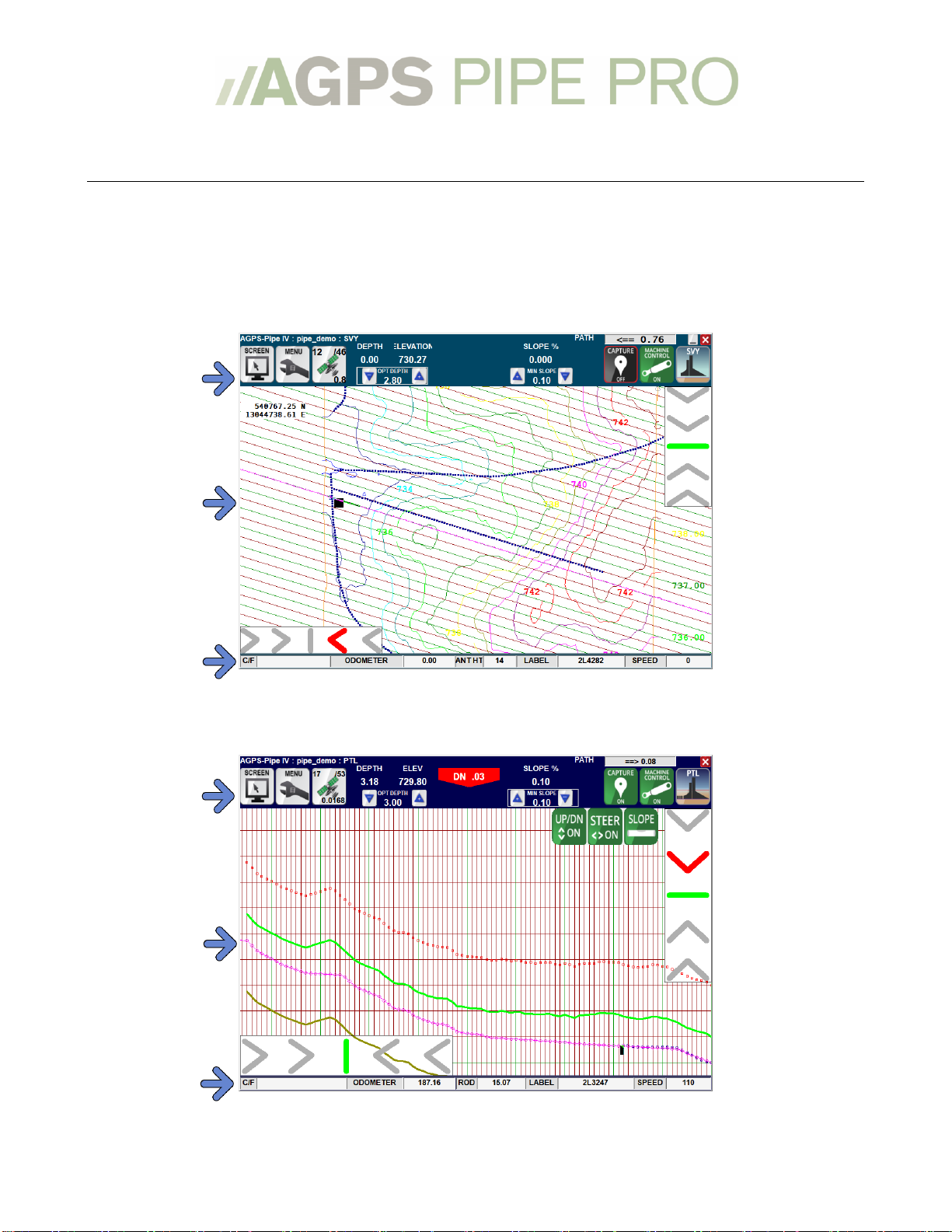

The Main Working Screen –Overhead View.......................................................................................................7

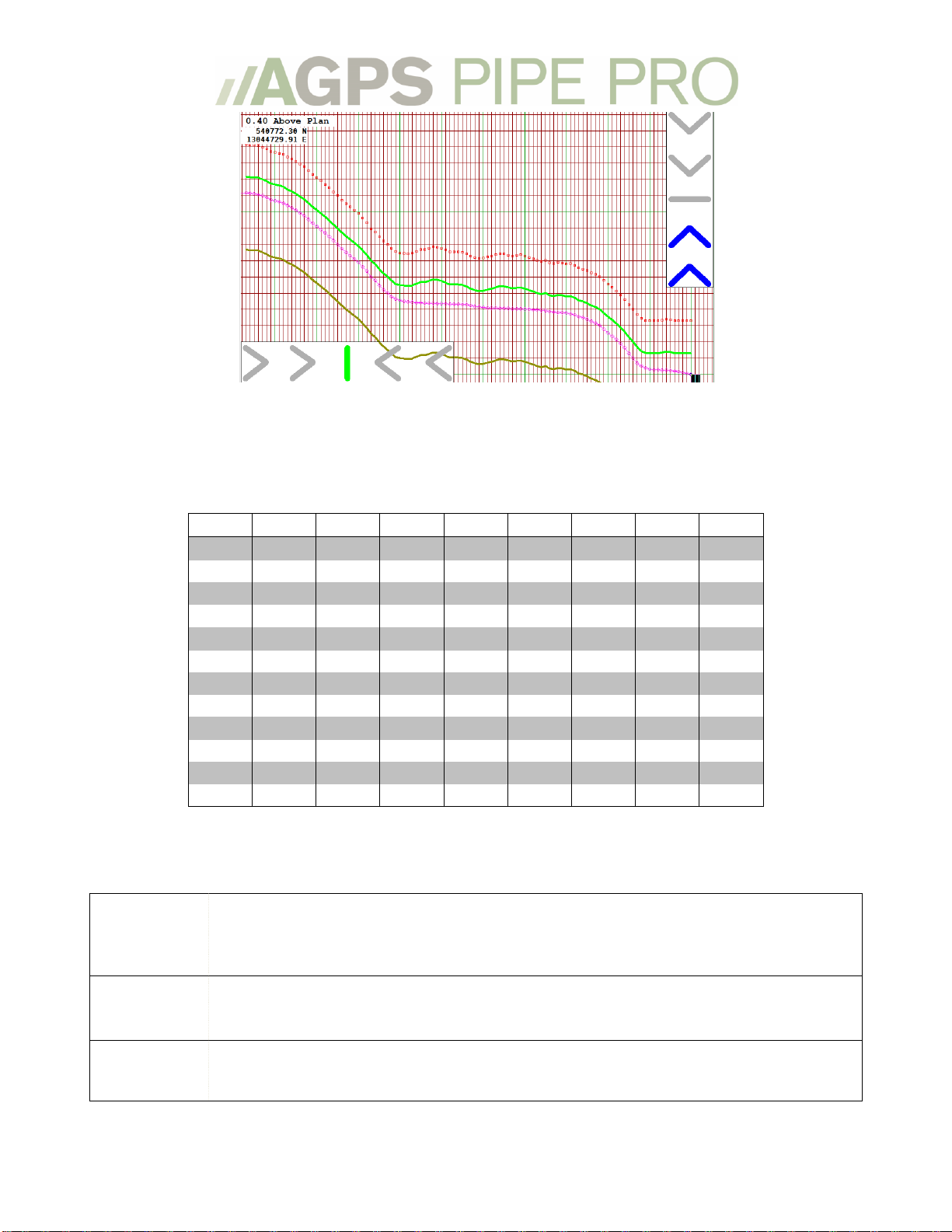

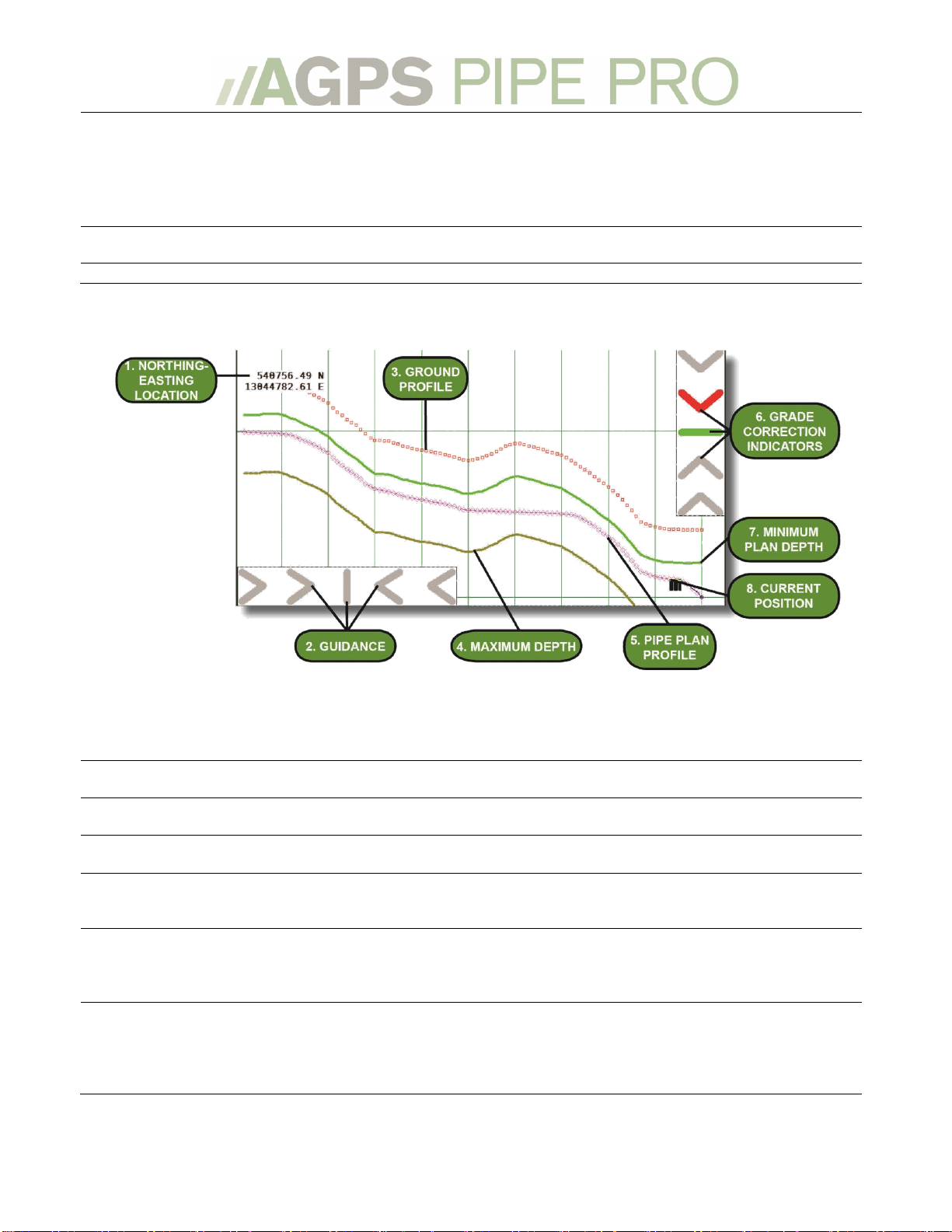

The Working Screen –Profile View........................................................................................................................7

The Working Screen –Menu Bar.............................................................................................................................8

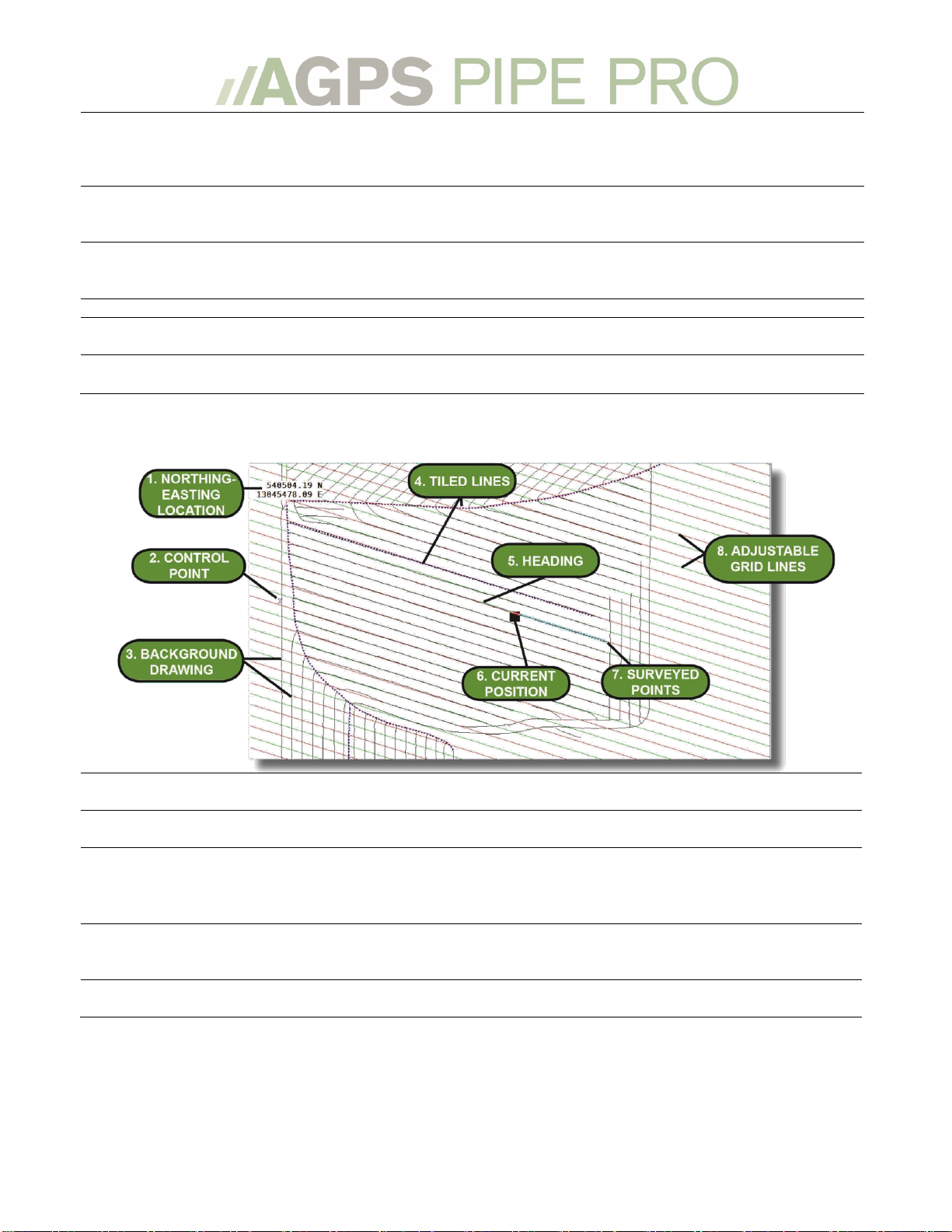

The Plot Screen –Overhead View............................................................................................................................9

The Plot Screen –Profile View.............................................................................................................................. 10

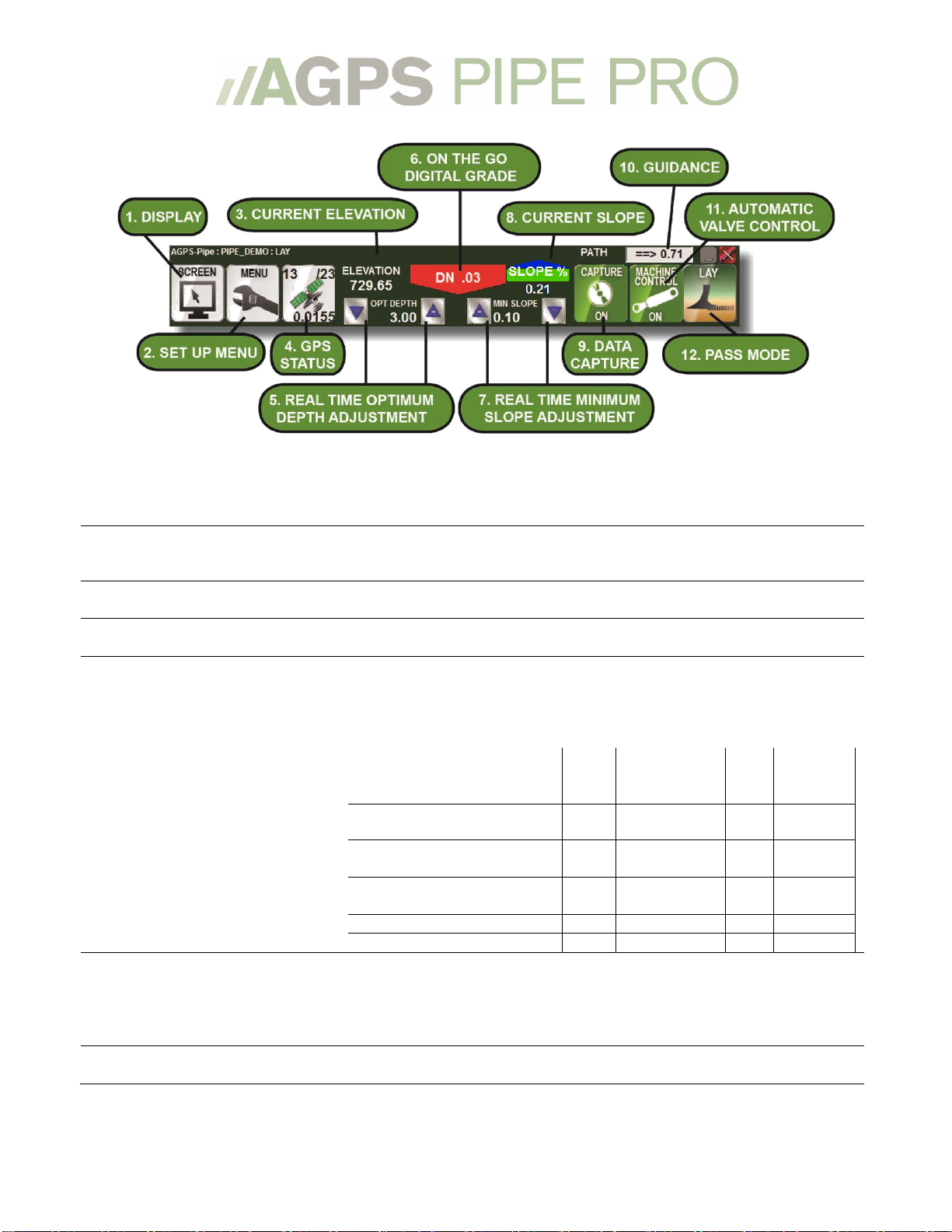

The Working Screen –Info Bar............................................................................................................................. 11

Setting up the program................................................................................................................................ 11

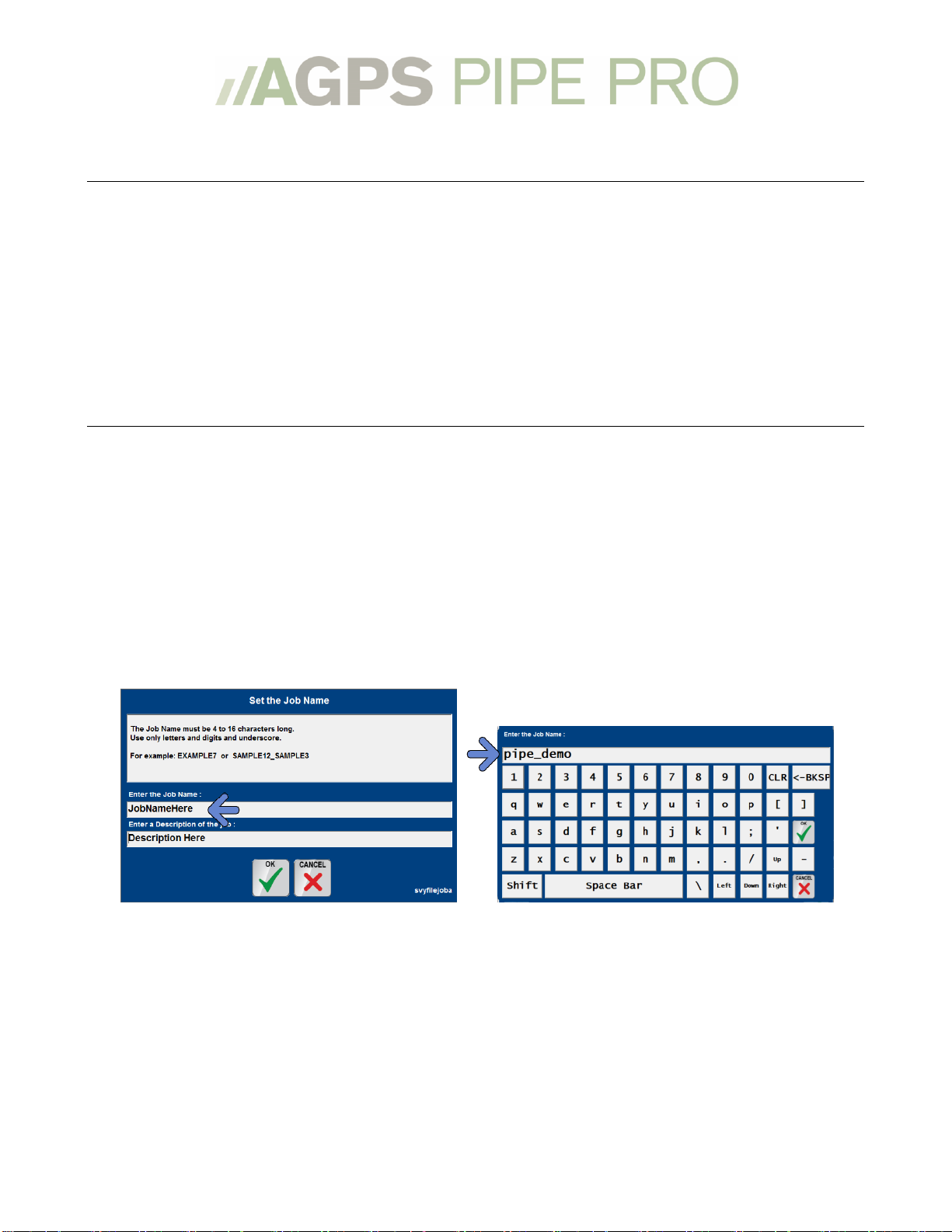

Setting up the program for the first time:......................................................................................................... 11

Starting a New Job or Restarting a Current Job, via Dashboard: .............................................................. 15

Start/Restart a Job, via menus:............................................................................................................................. 17

Working with RTK-GPS ...............................................................................................................................19

Configuring my GPS .................................................................................................................................................. 19

GPS Status..................................................................................................................................................................... 19

Troubleshooting my GPS ........................................................................................................................................ 20

Rod Length and Survey Pass Offset..................................................................................................................... 21

Rod Length.................................................................................................................................................................................21

Survey Pass Offset................................................................................................................................................................... 21

Rip-Lay Vertical Distance.....................................................................................................................................................21

Working with the Program ........................................................................................................................22

Adjusting the view..................................................................................................................................................... 22

The Buttons Menu...................................................................................................................................................................23

The Click Menu.........................................................................................................................................................................24

The Light Bars............................................................................................................................................................. 25

The Light Bar Menu................................................................................................................................................................26

The Grid ........................................................................................................................................................................ 27

Setting up the Grid..................................................................................................................................................................27

Using the Grid ...........................................................................................................................................................................29

Loading Background Images................................................................................................................................. 29

Laying Tile........................................................................................................................................................ 30

Pass Labels................................................................................................................................................................... 30

Reading a pass label ...............................................................................................................................................................30

Selecting a Pass Label............................................................................................................................................................30

Pass Types.................................................................................................................................................................... 32

Survey Pass.................................................................................................................................................................. 33

Creating a Survey Pass..........................................................................................................................................................33

Rip Pass......................................................................................................................................................................... 34

Creating a Rip Pass .................................................................................................................................................................34

Recalling a Previously Captured Survey or Rip Pass.................................................................................... 36