1Introduction ..................................... 5

1.1 Validity of the manual ...................... 5

1.2 Other applicable documents ............ 5

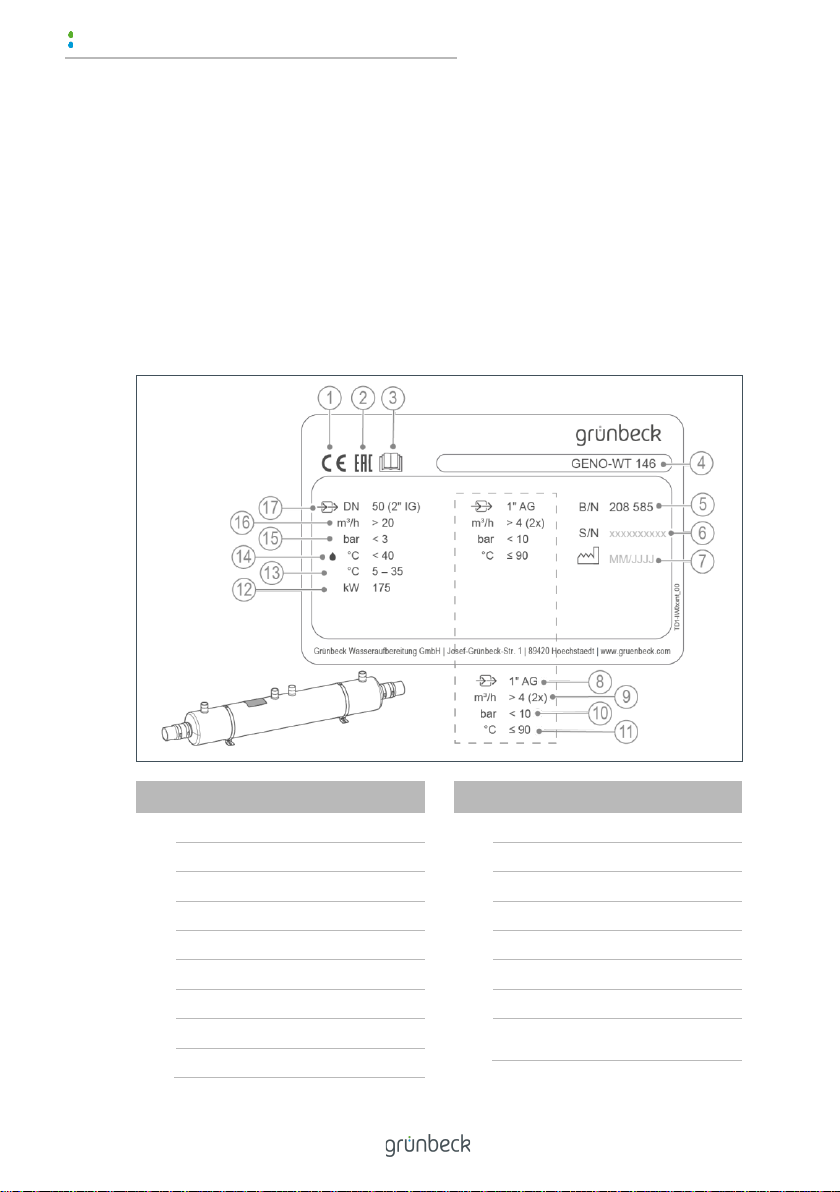

1.3 Product identification ....................... 6

1.4 Symbols used .................................. 7

1.5 Depiction of warnings ...................... 8

1.6 Requirements for personnel ............ 9

2Safety ............................................. 11

2.1 Safety measures............................ 11

2.2 Product-specific safety

instructions..................................... 13

2.3 Conduct in an emergency.............. 14

3Product description ...................... 15

3.1 Intended use.................................. 15

3.2 Product components...................... 16

3.3 Accessories ................................... 17

4Transport and storage.................. 18

4.1 Dispatch/delivery/packaging .......... 18

4.2 Transport ....................................... 18

4.3 Storage .......................................... 18

5Installation ..................................... 19

5.1 Requirements with regard to the

installation site ............................... 23

5.2 Checking the scope of supply........ 24

5.3 Installing the heat exchanger......... 25

6Start-up .......................................... 31

6.1 Venting the system/checking for

leaks .............................................. 32

6.2 Checking the system function........ 33

6.3 Handing over the product to the

owner/user..................................... 33

7Operation/handling....................... 34

8Maintenance and repair................ 35

8.1 Cleaning ........................................ 36

8.2 Intervals ......................................... 36

8.3 Inspection ...................................... 37

8.4 Maintenance .................................. 38

8.5 Spare parts .................................... 40

8.6 Wearing parts ................................ 40

9Fault ............................................... 41

9.1 Observations ................................. 41

10 Shut down...................................... 42

10.1 Temporary standstill ...................... 42

10.2 Restart ........................................... 42

11 Dismantling and disposal ............ 43

11.1 Dismantling.................................... 43

11.2 Disposal......................................... 44

12 Technical specifications .............. 45