7

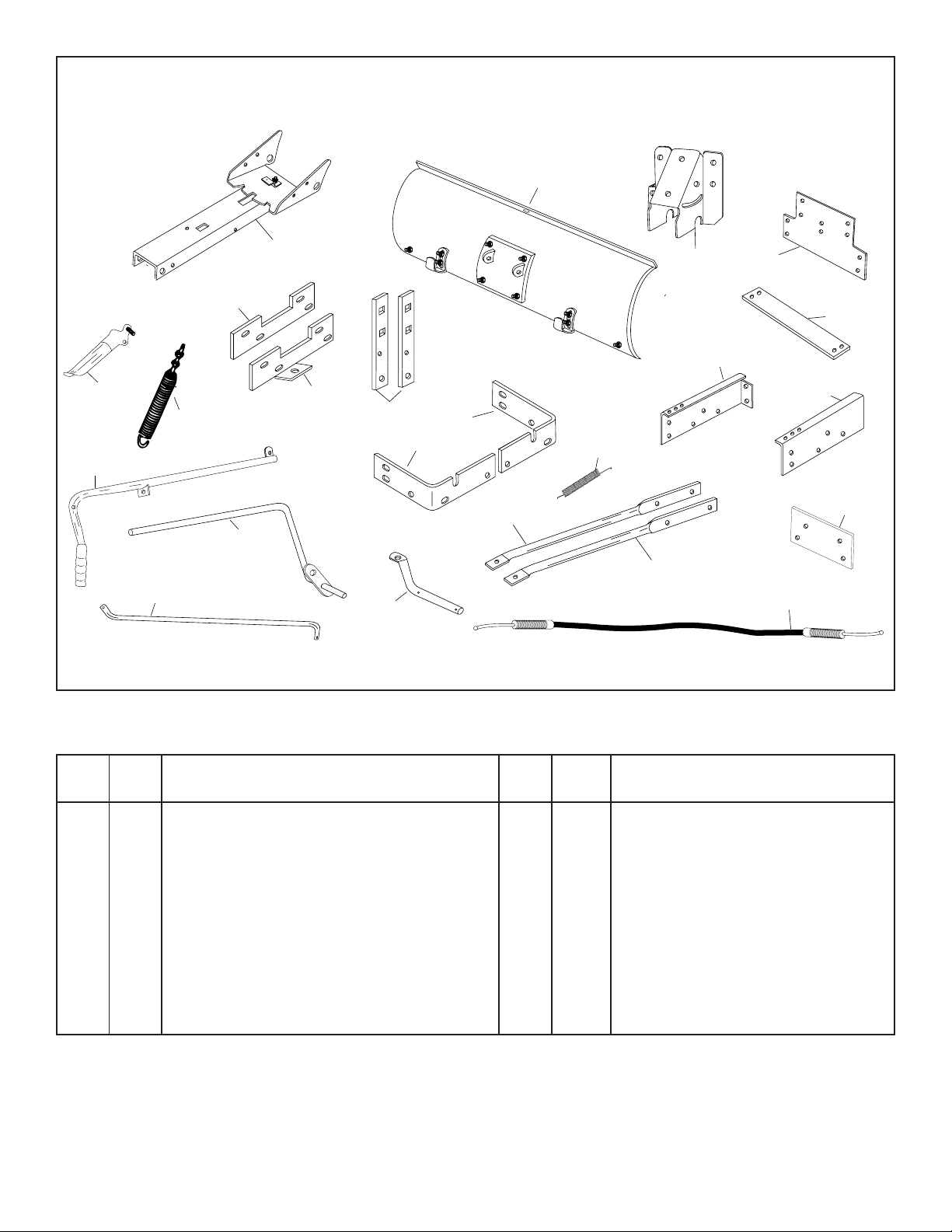

FIGURE 10

A gle lock bars should pivot freely; a d whe

they are pulled all the way back, the cha el/

pivot plate assembly should be u locked a d

free to pivot to right or left positio otches.

NOTE:

(Right Hand Side View)

Assemble the two a gle lock bars together as show i

figure 9 so that all holes are alig ed. Use o e 3/8" x 1-

1/4" carriage bolt, o e 3/8" lock washer a d o e 3/8" hex

ut. Be sure to i sert bolt from side i dicated. Do not

tighten at this time. See figure 9.

(Right Hand Side View)

FIGURE 9

I sert straight e d of a gle lock spri g through middle

hole i a gle lock bars so that hook ope i g o other e d

of spri g is faci g up towards square holes i bars as

show . Assemble hook e d of a gle lock spri g up

through bottom of hole i bracket (A). See figures 9 a d

10.

To assemble a gle lock bars to cha el use o e 1/4" x

3-1/4" hex bolt, o e hex lock ut a d two 1" lo g spacers.

Pull o a gle lock bars to exte d spri g just e ough to

allow i sertio of bars dow through slot i cha el a d

pivot bracket. Alig i g the spacers o both sides of

a gle lock bars u der eath cha el, i sert bolt through

holes i sides of cha el a d through the a gle lock bars

a d the two spacers. Assemble the lock ut to the bolt o

outside of cha el. Tighte so that lock bars pivot freely.

See figure 10.

At this time tighten the 3/8" carriage bolt and hex nut

previously assembled to angle lock bars.

FIGURE 12 (Right Hand Side View)

Assemble 3/8" x 1-1/4" carriage bolt through square hole

i cable mou t bracket a d through square hole i a gle

lock bars. See figures 12 a d 13. Note that top bolt faces

i opposite directio . Hold cable mou t bracket i posi-

tio as show i figure 12 a d secure with 3/8" lock

washer a d 3/8" lock ut. Tighten. See figures 12 a d

13.

FIGURE 11 (Top View)

Usi g a hammer, drive a 3/8" pal ut o to o e e d of

spri g mou t rod. I sert the other e d of the spri g

mou t rod through the rear holes o both sides of the

pivot plate. Support e d (with pal ut) of the spri g

mou t rod with a block of wood, a d hammer o the

remai i g pal ut. See figure 11.

At this time tighten all items previously left untight-

ened.

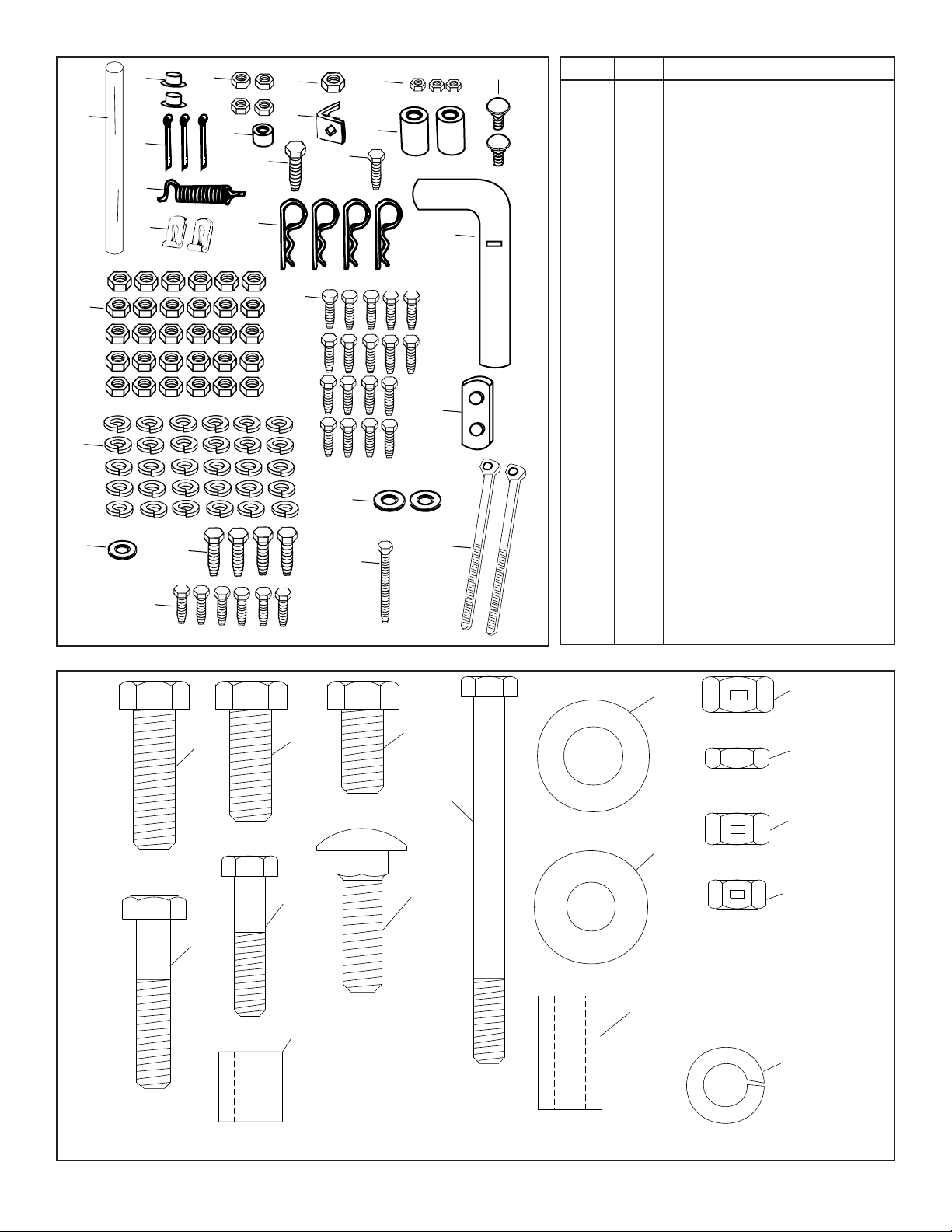

3/8" CARRIAGE BOLT

3/8" LOCK WASHER

3/8" HEX NUT

ANGLE LOCK

BARS

BRACKET (A)

SLOT

ANGLE LOCK SPRING

1/4" x 3-1/4" HEX BOLT

1" SPACERS (2)

1/4" LOCK

NUT

1/4" LOCK

WASHER

PIVOT

BRACKET

ANGLE LOCK SPRING

BRACKET (A)

CHANNEL

3/8" PALNUT

PIVOT

PLATE

SPRING

MOUNT

ROD

3/8" PALNUT

3/8" x 1-1/4"

CARRIAGE BOLT

3/8" LOCK

NUT

CABLE MOUNT

BRACKET

ANGLE LOCK BARS

3/8" LOCK

WASHER