2

INTRODUCTION

Please peruse the contents in the instruction manual prior to use this machine, correctly carried

out installation and debugging, as well as used it strictly cording to the working specifica-

tion in the instruction manual. The user should be familiar with the safety notices, machine

performance, and maintenance, etc. The instruction manual will be used in the later use, repair,

accessories replacement, and accessories procurement, so please keep it carefully

OPERATING INSTRUCTION

1 Securely mount the machine on the frame, ensured the two belt pulleys be parallel and

on the same plane, and the tension of belt be moderate;

2 Add 30~40# machine oil up to 1/2 of oil gauge plug;

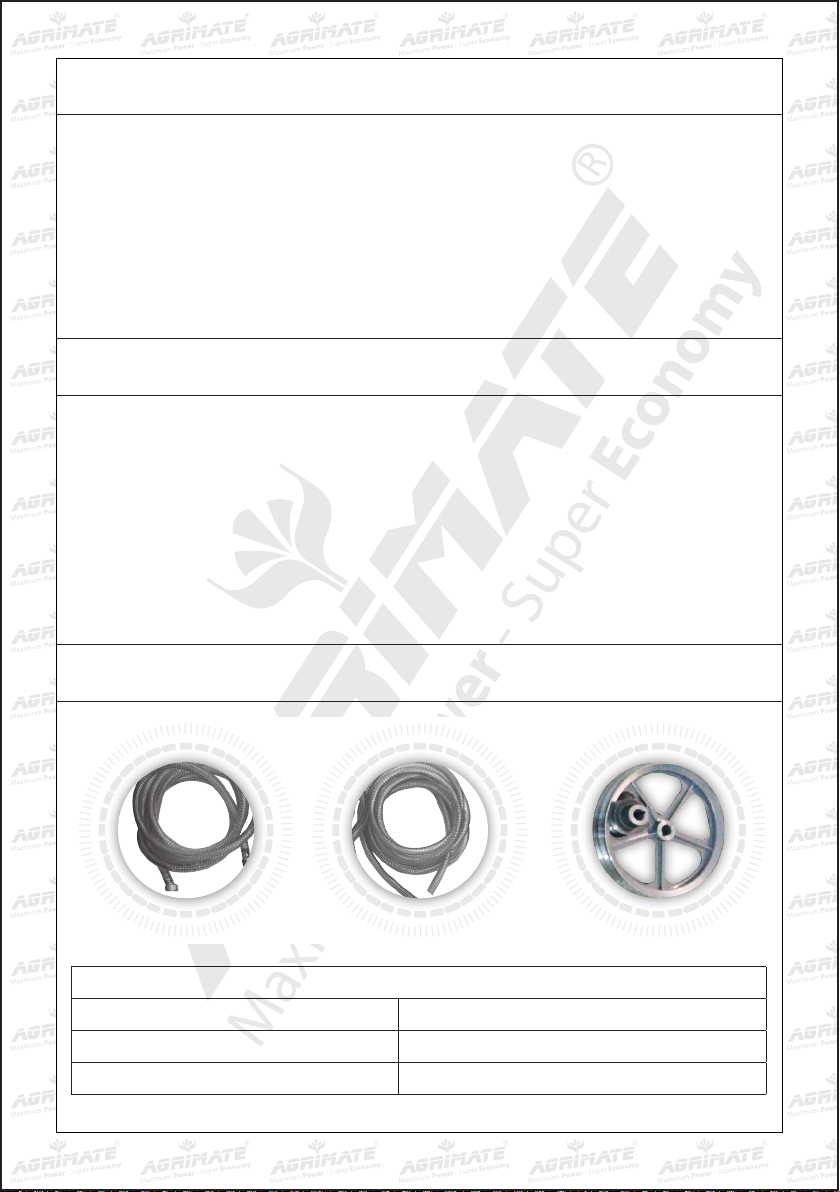

3 The connectors of each rubber pipe and high pressure pipe must be locked tightly ;

4 Before start the motor, open the jet gun and ball cock, and loosen the adjusting screw;

5 Start the motor, keeping it at appropriate velocity; Waiting there is water ejecting from

the jet gun , close the jet gun or ball cock, and adjust the adjusting screw to let the pres-

sure reach the working pressure;

6 Turn on the ball cock and jet gun, beginning spraying. During the process may properly

adjust the adjusting screw to maintain the required pressure, and lock tightly the fly nut

at any moment;

7 After spraying , operate the sprayer with clean water for 2~3 minutes to clean the residu-

al interior chemicals;

8 Firstly dismantle the suction hose, waiting there is no water flowing out from the jet gun

or the overflow hose, stop the machine and dismantle over flow hose, high pressure pipe,

and loosen the adjusting screw.