Ae-man-421-0.0 v1.0 TECHNICAL MANUAL

HEADQUARTER OFFICE & FACTORY: C/ Julián Camarillo, 26 28037 – MADRID (SPAIN)

Phone.:+34 91 754 55 11 ww.aguilera.es 2

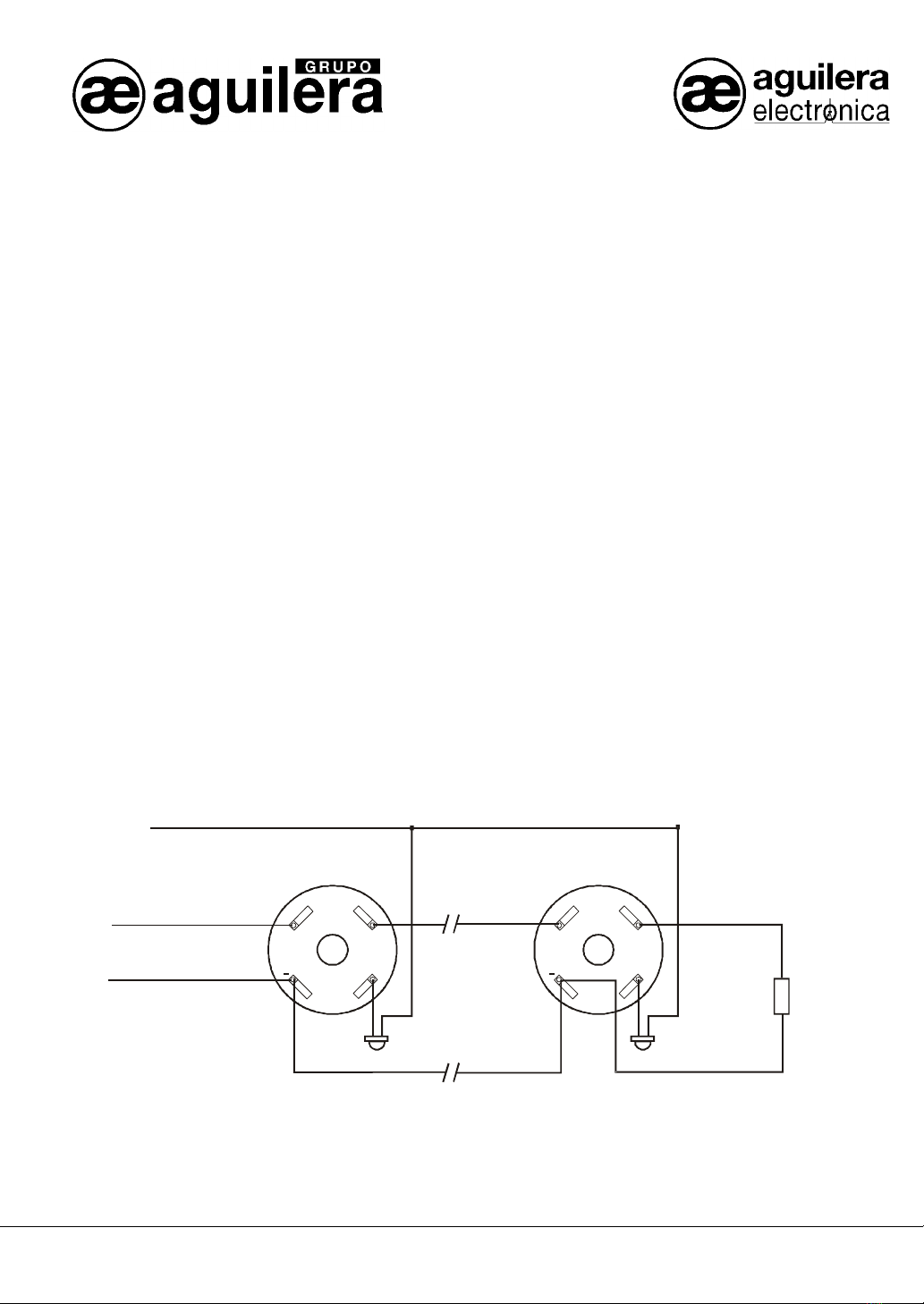

Installing the head

§Align the components as show in the Figure.

§Mate the detector head into the base and twist clockwise to secure it.

§The maximum number of detectors installed in the same loop is 30 units.

§After all detector have been installed apply power supply to the detector loop.

CAUTIONS.

§To prevent detector from dirty effect and warranty cancellation, the smoke detector

must remain covered until the area is clean and dust free.

§Detector protection cover is not intended to provide complete protection against dust

ambient pollution, therefo re detector should be removed before beginning to m ade

masonry works, inner space revamping or other dust producing activity.

§Do not paint any part of detector because paint can close air entry holes and then detector operation will be affected.

§Detector protection cover must be removed before fire detection system can be made operational.

TESTING.

Detectors must be tested after installation and following periodic maintenance.

Before testing, notify to the proper authorities that the detector system is undergoing maintenance, and be sure that all required functions related

to alarm emergency exit, extinguishing system and automatic extinguishing shoot in are cancelled.

§Check that when you remo ve each detector fr om the base the fi re alarm panel will be move announcing zone fault notice. If no an y fault is

coming then recheck that there are not placed 2 wires or more at the same detectors base clamp at the + terminal block.

§Check to see if the indicator LED is flashing . If green LED fails to flash, it indicates the detector non-operation condition or a faulty wiring is

made.

§Apply some smoke sample f rom a test smoke aerosol to each detector during at l east 10 sec onds to acti vate the detector- sensing

chamber. When sufficient smoke portion has entry within the chamber then detector wil l generate an alarm signal being recognized

externally by a continuous lighting from the external LED and fire alarm panel shall be in alarm mode.

§If a remote LED annunciator is coupled then als o shall be light activated. If lighting activation does not arrive checking for wiring and well

done detector plug-in into base is required to be done it again

§To made same detector testi ng as above mentioned for another selected detector placed at the sam e detection l oop, first at all y ou shall

reset the loop by switching-off from the rem ote fire alarm panel and also check the zone is in stand-by mode before start-up with the next

one detector checking.

All detectors not capable to perform testing as above indicated must be replaced for technical service attendance.

After testing implementation the alarm emergency exit, extinguishing system and automatic extinguishing shoot in functions cancelled previously

at the fire alarm panel shall be activate and proper authorities shall be informed that the fire alarm system is again in operation.

DETECTOR MAINTENANCE GUIDELINE.

The recommended minimum requirement for detector maintenance consists of an annual cleaning of dust from the detector head using a vacuum

cleaner. All ambient head detector entry holes shall be keeping totally cleaned from ambient entry obstacles. For an exhaustive clean treatment

the detector head should be send to AGUILERA ELECTRONICA, Customer Assistance Department.

Do not attempt to disassemble factory sealed detector head. Opening the detector head the detector warranty will be void.

SPECIFICATION.

DC:PowerSupply 18 ~ 28 Vdc

Standby current: 180 µA

Alarm current: 22 mA max.

Loop Wires sizes: 2 X 1 mm2

Operating Temperature Range: 10ºC a +50º C ambient dry temperature.

Operating Humidity Range: 10% al 90% Relative Humidity, Non-condensing.

Lighting Annunciators: Standby: Led flashing.

Alarm: Continuous red lighting from LED

Remote alarm output, rate: Remote LED annunciator.

Detector Dimensions: Cover : 105 mm. (Diameter)

Cover Height with base: 76 mm.

Raw Material: White ABS plastic.

EN 54-7:2001

099

099/CPD/A74/0018