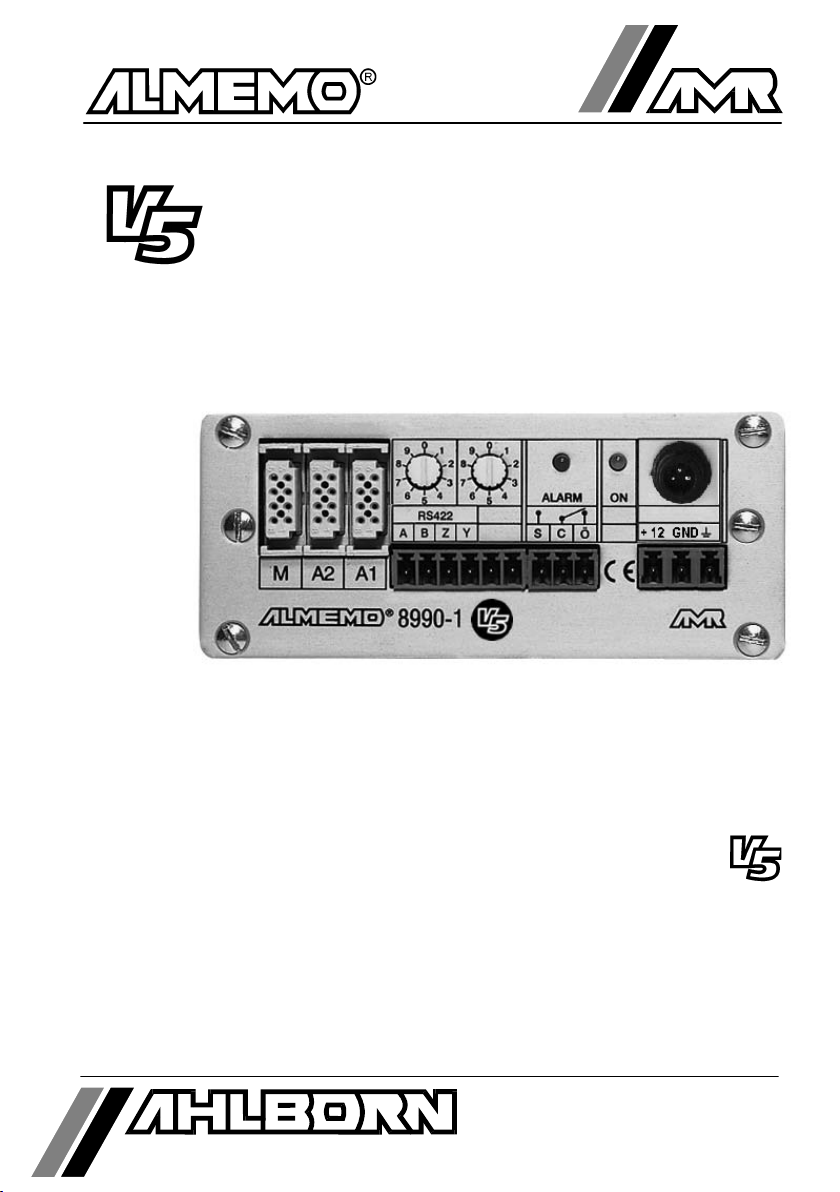

4. CONNECTION OF THE TRANSDUCERS

Any ALMEMO®sensors can be easily connected to the ALMEMO®input socket

M (11). For connecting existing sensors with open ends it is only necessary to

connect a corresponding ALMEMO®connector.

The connection of the sensors should be performed very thoroughly as it can

have large effects on the electromagnetic compatibility. Although the

measuring input is electrically isolated from the outputs, it is advisable to

isolate the transducer when installing because the protective earth connection

and the housing can often provide high voltage transients in industrial

environments. When performing the cabling it must be considered that the

leads are not wired near magnetic valves, contactors and motors and that they

are not guided together with leads for such devices. The leads should be as

short as possible and should have a cross section of 0.5 mm² at minimum (1.0

mm² at max.). Furthermore, electromagnetic influences can be reduced by

twisting the lines or by guiding cables in steel tubes. Electrostatic disturbances

can be avoided by using shielded cables. The metal braid shield is then

connected to the ´-´ terminal of the connector.

4.1 Transducers

A detailed description of the comprehensive ALMEMO®sensor range and the

connection of existing sensors to the ALMEMO®instruments are provided in

the ALMEMO®manual (s. man. sect. 3 and 4). All standard sensors with

ALMEMO®connector usually have the measuring range and dimension already

programmed and can be immediately connected to any input socket. A

mechanical coding ensures that sensor and output modules can only be

connected to the correct sockets. Furthermore, each ALMEMO®connector has

two locking levers that snap in when the insertion into the socket is established

and that prevent a disconnection caused by pulling the cable. Both levers must

be pressed on the sides for disconnecting the connector.

The programming of the sensor connectors can, with the transmitter

ALMEMO®8990-1, only be changed via the serial interface (see man. section

6). However, this can be carried out by using the PC and the configuration

software AMR-Control or any terminal application (e.g. Windows Terminal) and

using very simple commands. Due to the data storage within the connector, it

is also possible to perform the programming with any of the ALMEMO®

instruments, which are equipped with a keyboard. The sensor connector must

be connected to the selected channel. When programming, it must be

considered that factory-programmed parameters are, by a locking mode,

protected against unintentional modification and that the locking level must first

be reduced before desired changes can be performed. The connectors ZA

9000-FS are not locked and are, therefore, most suitable for programming by

the user.

10 ALMEMO8990-1

Connection of the Transducers