ahn myLab UC-01 User manual

AHN myLab UC-01

Universal Centrifuge 4500 rpm

Instruction Manual

CONTENTS

1. INTRODUCTION 1

2. INTENDED USE 1

3. SALIENT FEATURES 1

4. STANDARD ACCESSORIES 1

5. TECHNICAL SPECIFICATIONS 1

6. SAFETY PRECAUTIONS 2

7. INSTALLATION 3

Ÿ Locaon and Mounng

8. USER INTERFACE AND DISPLAY 4

9. OPERATING THE CENTRIFUGE 5

Ÿ Switch on the Centrifuge

Ÿ Speed Seng

Ÿ Time Seng

Ÿ Acc/Dcc

Ÿ PRG

Ÿ Quick Spin

Ÿ PEdit program

Ÿ Rotor

Ÿ Start & Stop

10. MAINTENANCE AND CLEANING 7

11. TROUBLESHOOTING 7

12. WARRANTY STATEMENT 9

13. PRODUCT DISPOSAL 10

1. INTRODUCTION

This centrifuge is equipped with a maintenance free drive, a large display & simple

interface for efficient operaon for daily lab usage. The programmable centrifuge

can deliver up to 4500 RPM and can accommodates different types of rotors. It

features various programmable mode to save me & add convenience.

2. INTENDED USE

Centrifuge is used in laboratories to separate parcles from liquid suspension

according to their density. The different biological substances that are usually

separated by centrifugaon are cells, mammalian cells, organelles, etc. It is

majorly used in laboratories.

Note: Before using the centrifuge, please read this user manual carefully. This user manual is

intended to assist with the operaon and care of the unit only and not its repair. For repairs

please contact the supplier.

3. SALIENT FEATURES

Centrifuge has following features:

• Delivers up to 4500 RPM for all compable rotors

• BLDC maintenance free motor drive

• Imbalance detecon safety with auto cutoff feature

• Lid lock safety feature : Lid does not open during operaon

• Program mode for customized operaon

• Speed seng by RPM/RCF mode

• Countdown mer range from 1 to 99 minutes

• Last run memory feature

• Convenient and easy user interface

• Emergency lid release during power cutoff

• Automac internal diagnosis & error display

4. STANDARD ACCESSORIES

• Power Cord

• T - Allen key

• User manual

• Warranty card

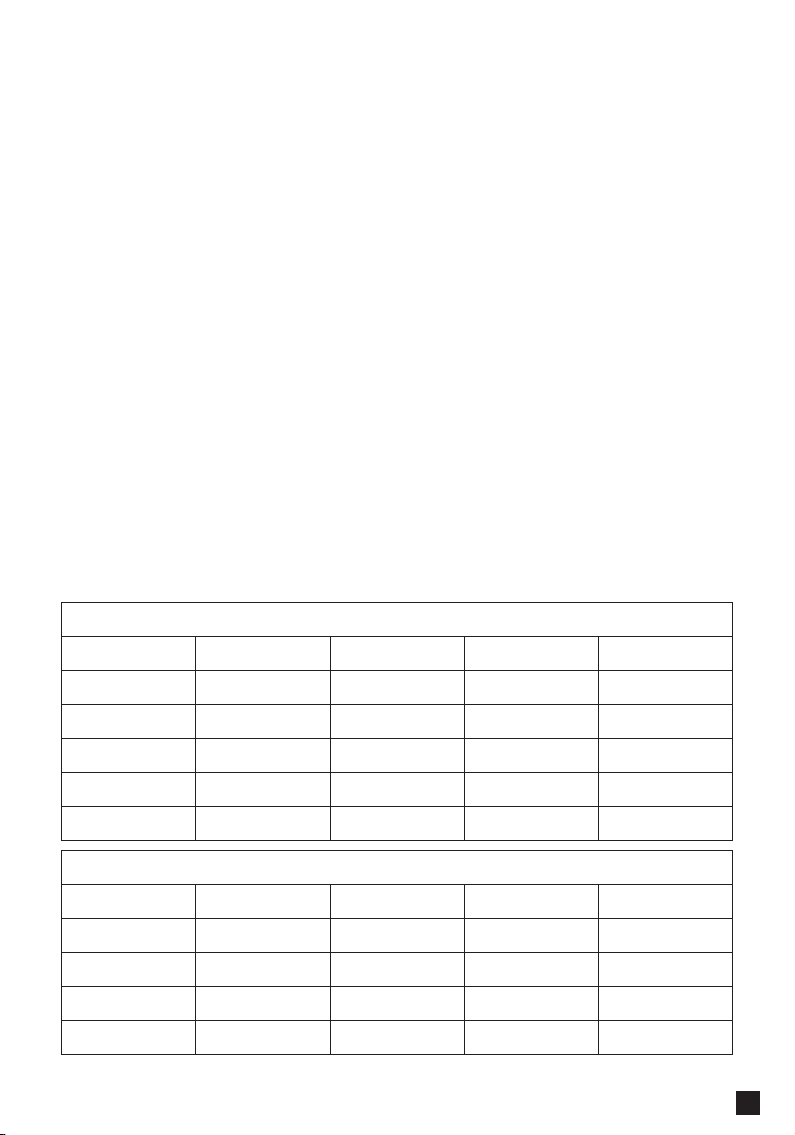

5. TECHNICAL SPECIFICATIONS

1

Motor Type Brushless DC Motor

Max capacity 400ml (4x100ml)

Speed Setting Variable 500 - 4500 rpm (Step of 100 rpm)

2

6. SAFETY PRECAUTIONS

ŸNever use the centrifuge in any manner not specified in this manual.

ŸAlways use recommended original rotors and spare parts for best result &

product safety.

ŸThe rotors must be loaded symmetrically. Each tube should be counter

balanced by another tube of same weight.

ŸDo not use centrifuge or rotor that have not been correctly installed or shows

any sign of damage .

ŸThe rotor must always be securely fastened. If the centrifuge makes unusual

noise during operaon, the rotor fitment needs to be checked. Switch OFF the

device immediately by pressing STOP, check fitment & fasten it well.

ŸNever move the centrifuge during its operaon.

ŸPrior to centrifugaon, the tubes should be visually inspected for material

damage. Damaged tubes must not be centrifuged. This is because broken

tubes can result in sample loss and can create imbalance which can result in

Ÿfurther damage to the centrifuge and accessories.

ŸDo not fill tubes while they are in the rotor. Liquids spillage may harm the

device. If liquids are spilled on the rotor or rotor chamber, the centrifuge must

be cleaned carefully and properly before being used again.

ŸCentrifuge may be used for the specified applicaons only. It must not be

operated in a hazardous or flammable environment and must not be used to

centrifuge explosive or highly reacve substances. Also do not place the

Speed Accuracy ± 100 rpm

Run Time 1 min to 99 mins & infinite mode

Ambient Temperature 5 - 40°C

Permissible Relative Moisture <80%

Min. Acceleration Time 30 seconds

Min. Deceleration Time 30 seconds

Noise Level <65 dB

Size (L x B x H) 475 x 585 x 325 mm

Weight 23 Kg (without rotor)

Input Power 110 V 230 V

Power Consumption 300 W 460 W

3

potenal hazardous material within the clearance area/envelope.

ŸEquipment if used in any manner not specified in this manual or by the

manufacturer can result in the lapse of the product warranty.

ŸRepairs must only be performed by authorized service technician.

ŸDo not lean on the equipment. It may damage the equipment or even harm the

operator.

ŸIn the event of contaminaon caused by aggressive agents, the rotor must be

cleaned immediately using a natural cleaning liquid. This is parcularly

important for the bores of the tubes. If any damage is seen, contact the service

technician.

ŸBefore using cleaning or decontaminaon methods other than those

menoned by the manufacturer, contact the manufacturer to ensure that the

intended method will not damage the centrifuge.

ŸFor safety we have provided protecve earthing with power supply. Make sure

power supply is earthened.

7. INSTALLATION

The Laboratory centrifuge is supplied in packaging box. Open the box, remove the

packaging and gently place the centrifuge out of the box. Before 1st me usage,

open the centrifuge & ensure to remove all packaging from the rotor chamber.

Please keep all packaging in safe storage for at least 2 years for warranty purpose.

LOCATION & MOUNTING

Place the centrifuge on a flat, solid and leveled surface and ensure that all the four

feet of this centrifuge stand on the surface firmly. Avoid installing on slippery or

surface prone to vibraon.

• Ideal ambient temperature is 25° C ± 5°C, avoid placing the centrifuge in

direct sunlight.

• Keep clearance of at least 30 cm from all side for ease of usage.

• Keep away from heat or water to avoid sample temperature issues or

centrifuge failures.

• Do not place the centrifuge such that it becomes difficult to operate the

device.

4

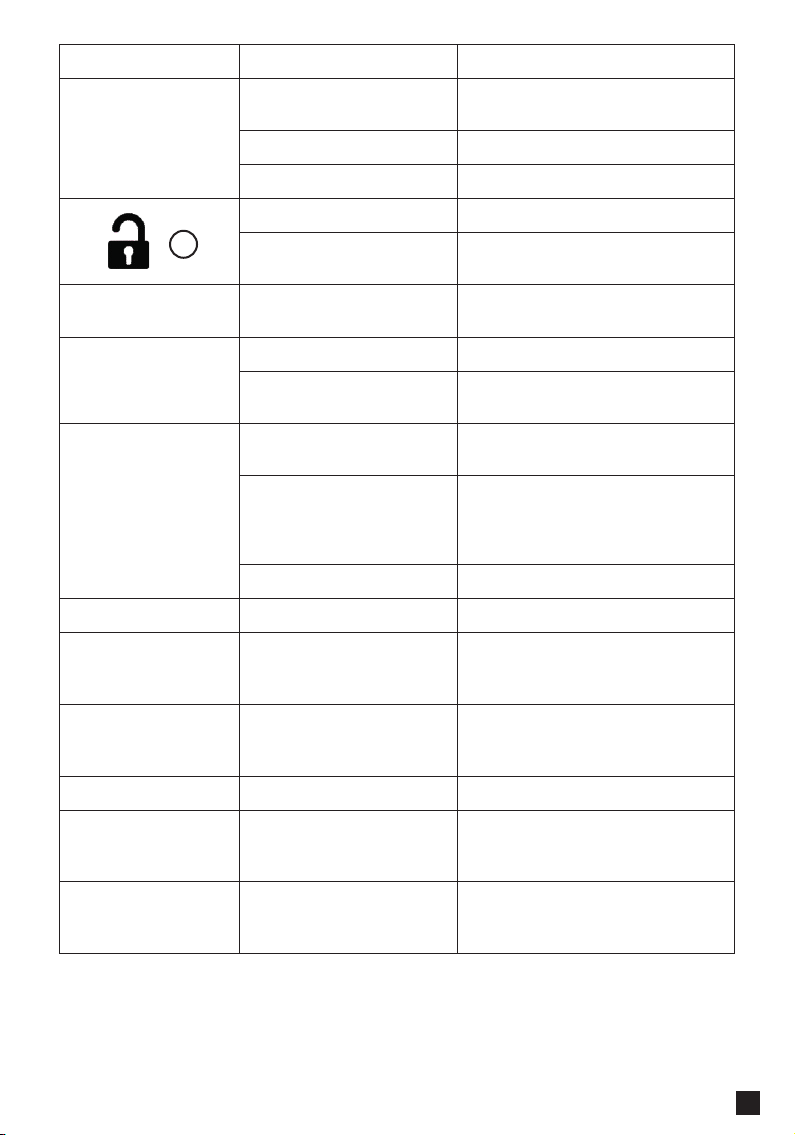

8. USER INTERFACE & DISPLAY

Item

Button Name

Function

Stop/open

RPM/RCF

Start

2

3

1

Single press, motor will start as per selected rpm and

time if lid closed. Start button works only if lid closed.

Motor start or stop, indicates with LED

Single press stop/open button, will stop motor as per

defined DCC time if motor is running. Second press stop/

open button, will open the lid if motor stopped. Also use

as lid open function if centrifuge motor is not running.

Single press, RPM will be display like 4500 and RPM LED

will blink. Long Press, RPM/RCF will toggle display to

RPM to RCF.

RPM , RCF mode also indicate via LED on panel.

4

5

Time

Increment /

Decrements

Single press, Time will be display like 99.00

Timer can be set from1 to 99 min.

Short press of {+}Plus and {-}Minus buttons will increase

and decrease speed, time, ACC, DCC values normally.

Long press of these keys would change the parameters

quicker

6

Acceleration

Deceleration

First Single press, Acceleration will display on time

segment like ACC1. We can change acceleration using

{+} and {-} buttons. (1 to 9).

Second Single press, Deceleration will display on time

segment like DCC1. We can change Deceleration using

{+} and {-} buttons. (1 to 9).

TIM E

RPM

RCF

PEdit

QUI CK

SPI N

PROG

SPEED TIME

RPM RCF

LID Run

START

ROTOR

STOP

OPE N

ACC

DCC

2

3 45

1

6 7

9

8

10

7

Rotor

To select among multiple rotors listed below

Pedit

Single press Pedit, SPEED/ TIME/ ACC/ DCC will blink

one after one 5 times on respective display and user can

change blinking parameters by using {+}Plus and {-}Minus

key. In PEdit mode user can also press SPEED/TIME/ACC/

DCC and change its value.

8

5

9. OPERATING THE CENTRIFUGE

SWITCH ON THE CENTRIFUGE

Aer connecng the power cord. Switch ON the main power supply & then Switch

on the power switch located on the right side of the instrument. Make sure to

check the rotor fitment before use. Centrifuge will not operate with open lid.

Note: Maintain a gap of 3 seconds between switch OFF and switch ON again. DO NOT switch OFF

and ON again instantly.

Speed Seng:

Press RPM/RCF buon to set speed from 500 to 4500 RPM. Single press to set

speed, long press to toggle mode RPM/RCF. The parameter can be set when the

speed screen blinks by using + buon for increment & "- "buon for decrement.

The values will automacally saves aer screen stops blinking.

Timer Seng:

Press the mer buon to set mer. Time can be set by + for increment & - for

decrement. The mer will save automacally once the blinking stops. The mer

can be set in minutes only while seconds are for countdown mer for running

operaon.

Acc/Dcc:

This buon will set the parameters of acceleraon or deceleraon of the rotor

ramp. Press acc/dcc buon once to set the acceleraon from 1-9 by using +/-

buon for increment/decrement respecvely. Similarly press once again the

acc/dcc buon to set deceleraon from 1-9 by using +/- buon for

increment/decrement respecvely. The values of accelaeraon & deceleraon

mings are listed below.

Quick Spin

Press hold for immediate centrifugation up to last set

RPM

10

PRG

Press PRG button to select the program from 1-99.

The different parameters can be set in each program

for quick selection.

9

-

-

Acc 1

Acc 2

Acc 3

Acc 4

480 Seconds

300 Seconds

180 Seconds

170 Seconds

150 Seconds

130 Seconds

dcc L

dcc 0

dcc 1

dcc 2

dcc 3

dcc 4

Acc 5

Acc 6

Acc 7

Acc 8

Acc 9

110 Seconds

90 Seconds

70 Seconds

50 Seconds

30 Seconds

dcc 5

dcc 6

dcc 7

dcc 8

dcc 9

6

PRG:

Press PRG buon to select the program from 1-99. The different parameters can

be set in each programm for quick selecon. To set parameters in each program

follow the parameters (Speed, me & Acc/Dcc) as described above. To select from

programs press using +/- buon for increment or decrement. All the parameters in

the program saves automacally once the blinking stops. The saved programs also

can be edited by following the instrucon of seng Speed, me & Acc/Dcc as

described above.

Quick Spin:

Press hold the quick spin buon for immediate centrifugaon of the samples up to

previous run RPM. Releasing the hold will stop of the rotor gradually.

Pedit:

Press PEdit buon to enter all the different parameters - Speed, Timer,

acceleraon & deceleraon automacally one aer the other. These parameter

will be asked by the instrument sequenally to be entered if required to be

changed (if not edited the display value will set). These parameters will save

automacally.

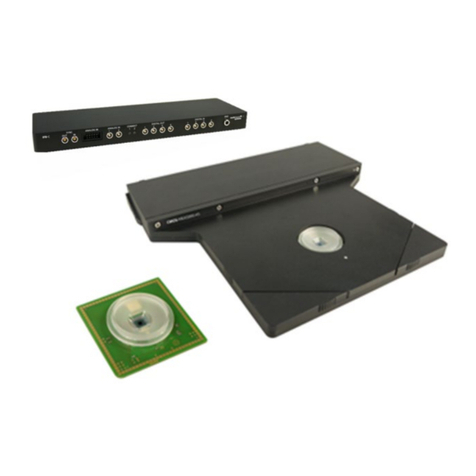

Rotor:

Press rotor buon to select rotors as listed below. The rotor numbers can be

changed by using +/- for increment or decrement of the rotor number.

Rotor Rotor No. Max. Volume Max. RPM Max. RCF

CR-43-100 Rotor 1

Rotor 3

Rotor 4

Rotor 25

Rotor 26

4 x 100 ml 4500 3164

CR-43-50 6 x 50 ml 4500 3530

CR-43-15 16 x 15 ml 4500 3485

CR-43-10

CR-43-PL

32 x 6 ml

2 x Microplates

4500

4500

3164

2355

Swing Out Rotors

Rotor 7CR-43-100F 4 x 100 ml 4500 2559

Fixed Angle Rotors

Rotor Rotor No. Max. Volume Max. RPM Max. RCF

CR-43-50F 6 x 50 ml 4500 2644Rotor 9

CR-43-15F-24 24 x 15 ml 4500 2852

CR-43-15F-16 16 x 15 ml 4500 3144

Rotor 10

Rotor 11

7

START & STOP

The centrifugaon can be started by pressing start buon once the desired

operaon set. The operaon can be stopped by pressing stop buon once. To

open the lid press stop/open key once aer the rotor comes to stop.

10. MAINTENANCE AND CLEANING

• The rotor and the outside of the centrifuge should be cleaned regularly with a

mild wet (with water) cloth.

• Ensure that while cleaning the unit is not plugging in.

• Wear protecve glove & safety glass while operang & cleaning the device.

• The brushless motor in the centrifuge requires no roune maintenance. Any

required service should be performed by authorized, qualified personnel

only. Repairs performed by unauthorized personnel may void the warranty.

• Always keep the centrifuge housing, rotor chamber and rotor clean. All parts

should be wiped down periodically with a so cloth. For more thorough

cleaning, use a neutral cleaning agent (Ph between 6 and 8) and clean with a

so cloth. Exclusive amounts of liquid should be avoided.

Note: Liquid should not come into contact with the motor.

• Aer cleaning, ensure that all parts are dry before re-use.

• Regularly cleaning of the rotor is important.

• If the rotor chamber needs cleaning, clean with cloth or sponge moistened

with a neutral detergent soluon.

• Do not place the rotor into the cleaning soluon.

• If corrosive, toxic or pathogenic bacteria are accidentally spilled in the rotor

or rotor chamber the centrifuge must be decontaminated throughly.

11. TROUBLESHOOTING

This centrifuge has a self – diagnosc funcon. If a problem occurs, an

error/warning code will be displayed on the display screen and the operator can

determine the malfuncon with the warning code below.

LC01-L30-134 6 x 50 ml 4500 2644

LC01-L30-137 24 x 15 ml 4500 2852

LC01-L30-131 16 x 15 ml 4500 3144

LC01-L30-132 12 x 15 ml 4500 3144

LC01-L30-133 8 x 15 ml 4500 2644

Rotor 9

Rotor 10

Rotor 11

Rotor 12

Rotor 13

8

IMPORTANT NOTE:

• If system get hangs or gets heated due to over current, switch OFF & switch

ON (restart) the centrifuge and check it again.

Rotor is still spinning. Wait for the rotor to come to a stop.

Emergency lid release after

rotor stops

Power failure

Centrifuge lid

cannot be opened

Rotor not loaded

symmetrically.

Load rotor symmetrically &

restart operation

Centrifuge shakes

during

acceleration &

exceptional

running noise

Either a broken tube,

damage to the rotor or

motor is cause for run

noise.

Rotor damaged. Remove & change rotor

Replace broken tube. For damaged

rotor/motor contact service

representative.

Contact service representative.

Loose connection of display.

Display error

Rotor not loaded

symmetrically.

Load rotor symmetrically & restart

centrifuge.

Err 55

No display

No main power

connection.

Power check & proper plug-in of

mains cable at both ends.

Power failure Check the mains fuse of the lab.

Connect adaptor properly.

Improper connection.

Lid not closed correctly. Close lid correctly.

Contact service.

Error with lid closing and

opening mechanism.

ERROR PROBLEM SOLUTION

Err 1 Latch damaged, Latch

jammed

Contact service

representative.

Err 52 Motor stuck or incorrect

operating voltage

Turn OFF the centrifuge, Check rotor

fitment or apply correct 230VAC ±

10VAC operating voltage

Remove cable and connect properly.

Cable not fit properly.

Power tripping

Turing ON centrifuge

immediately after

turning it OFF.

Last run memory

not displayed

Maintain 3 seconds gap Between

switch OFF and switching ON again.

Switch off centrifuge and then

switch it ON again. If the error still

shows, contact service representative.

Electronics error.

System gets hang

9

• Maintain 3 seconds gap between switch OFF and switch ON. Instant ON-OFF

can lead to a reset, erasing last run memory.

• If motor gets hot due to which there will be fluctuaon in speed value then

allow centrifuge to get cool for atleast 30 minutes. Do not do any operaon

for 30 minutes.

12. WARRANTY STATEMENT

This product is warranted to be free from defects in material and workmanship for

a period of Two (2) year from date of purchase. Your product will be duly repaired

upon prompt noficaon in compliance with the following condions :

This warranty is valid only if the product is used for its intended purpose and

within the guidelines specified in this instrucon manual. This warranty does not

cover damage caused by accident, neglect, misuse, improper service, natural

forces or other causes not arising from defects in original material or

workmanship. This warranty does not cover any incidental or consequenal

damages, commercial loss or any other damages from the use of this product.

The warranty is invalidated by any non-factory modificaon, which will

immediately terminate all liabilies on us for the products or damages caused by

its use. The buyer and its customer shall be responsible for the product or use of

products as well as any supervision required for safety. If requested the products

must be returned to the distributor in well packed and insured manner and all

shipping charges must be paid.

Some states do not allow limitaon on the length of implied warranes or the

exclusion or limitaon of incidental or consequenal damages. This warranty

gives you specific legal rights. This warranty is given expressly in lieu of all other

warranes, expressed or implied.

The purchaser agrees that there is no warranty of merchantability or of fitness for

any intended purpose and that there are no other remedies or warranes,

expressed or implied, which extend beyond the descripon on the face of the

agreement. This warranty is only applicable to the original purchaser.

Products received without proper authorizaon will not be entertained. All items

returned for service should be sent postage prepaid in the original packaging or

other suitable carton, padded to avoid damage. We will not be responsible for

damage incurred by improper packaging.

All items returned for service should be set postage prepaid in the original

packaging or other suitable carton, added to avoid damage.

This warranty is valid only if the warranty is registered with the supplier within 30

days from the date of purchase.

In case the product is to be disposed of, the relevant legal regulaons are to be

For your reference, make a note of the serial number, date of purchase and

supplier here.

Serial No. Purchase Date

Supplier

observed.

13. PRODUCT DISPOSAL

Informaon on the disposal of electrical and electronic devices in the European

Community

The disposal of electrical devices is regulated within the European Community by

naonal regulaons based on EU Direcve 2012/19/EU on waste electrical and

electronic equipment (WEEE). According to these regulaons, any devices

supplied aer 13.06.05 in the business to business sphere, to which this product is

assigned, may no longer be disposed off in municipal or domesc waste. They are

marked with the following symbol to indicate this.

As disposal regulaons within the EU may vary from country to country, please

contact your supplier if necessary.

10

0137-97-0000-02-003-R1

© 2020 AHN Biotechnologie GmbH

®

AHN Biotechnologie GmbH

Uthleber Weg 14

D-99734 Nordhausen

Germany

Phone: +49(0)3631/65242-0

Fax: +49(0)3631/65242-90

E-Mail: [email protected]

www.ahn-bio.de

Table of contents

Other ahn Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Velp Scientifica

Velp Scientifica ECO 6 instruction manual

Biosan

Biosan MMS-3000 User instructions

Thermo Scientific

Thermo Scientific HESI-II Probe user guide

Fritsch

Fritsch PULVERISETTE 5 operating instructions

Matec

Matec CHDF 2000 Hardware manual

Advanced Measurement Technology

Advanced Measurement Technology 273A user manual

Harvard Bioscience

Harvard Bioscience Multi Channel Systems Smart Ephys... System manual

Kendro

Kendro Sorvall Legend T instruction manual

Beckman Coulter

Beckman Coulter FP 1000 manual

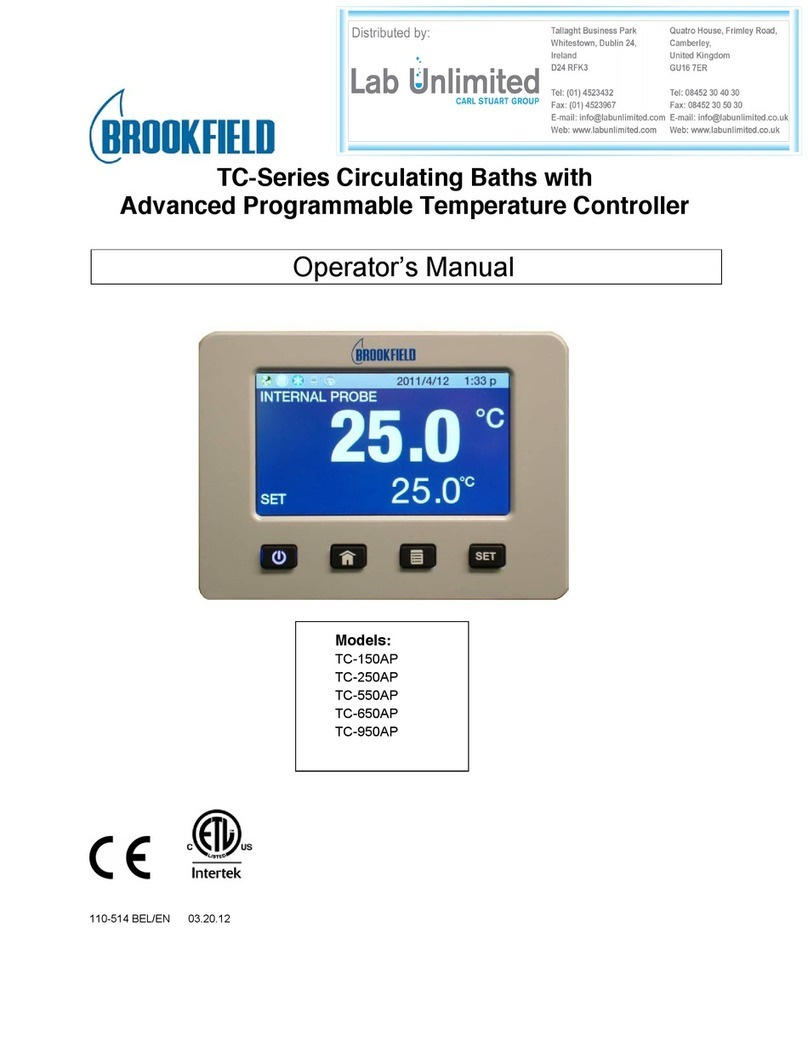

Brookfield

Brookfield TC Series Operator's manual

Metrohm

Metrohm 6.5330.210 manual

Thermo Scientific

Thermo Scientific NS-FANT12-CH Quick setup guide