Contents

1

Contents

For your safety............................................ 3

Proper use................................................................ 3

Improper use ............................................................ 3

Centrifuging hazardous materials ............................ 3

Handling the centrifuge ............................................ 4

Conformity to current standards............................... 5

Safety instructions in this manual ............................ 5

The Legend™ T / RT................................... 7

Description ............................................................... 7

Safety systems......................................................... 8

Parts supplied .......................................................... 8

Function and features .............................................. 9

Before use................................................. 13

Centrifuge transport and installation ...................... 13

Proper location ....................................................... 13

Main connection ..................................................... 14

Rotors and accessories ........................... 15

Rotors for the Legend™ T...................................... 16

Rotors for the Legend™ RT................................... 21

Handling the rotor................................................... 31

Aerosol-tight operation........................................... 36

Checking of aerosol-tight bio-containment......... 39

Operation .................................................. 41

Switching on the centrifuge .................................... 41

Actuating the lid...................................................... 41

Opening the lid ................................................... 41

Closing the lid ..................................................... 41

Installing the rotor................................................... 42

Loading the rotor .................................................... 43

Maximum loading ............................................... 43

Filling the centrifuge tubes ................................. 44

Maximum permissible load difference................ 44

Inserting the centrifuge tubes ............................. 45

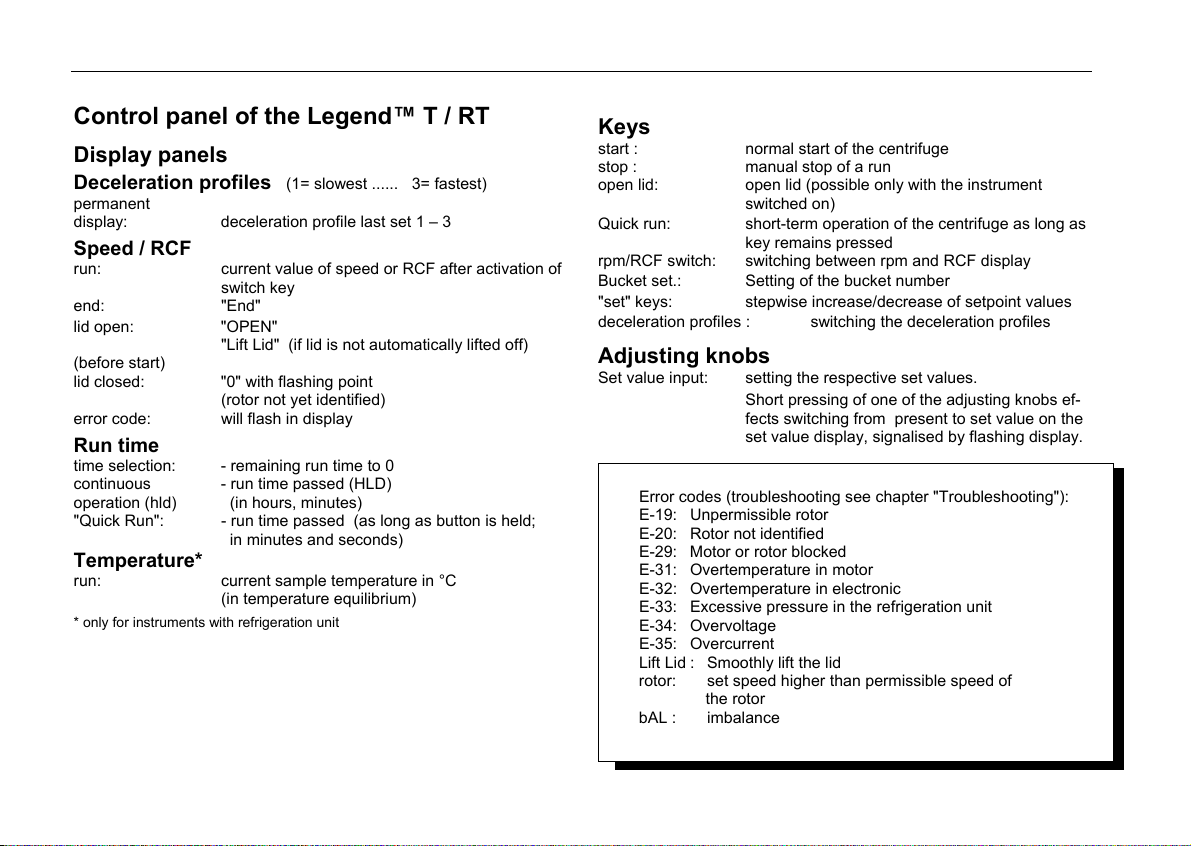

Entering parameters............................................... 47

Deceleration curves ............................................... 47

Switching from speed to RCF display .................... 47

Bucket selection for swinging bucket rotors........... 47

Selecting speed...................................................... 48

Entering the RCF value.......................................... 48

More about the RCF value ................................. 49

Selecting run time .................................................. 49

Run time selection.............................................. 49

Continuous operation ......................................... 50

Extended time mode........................................... 50

Selecting the temperature ...................................... 51

Starting the centrifuge ............................................ 51

Imbalance display .................................................. 52