1.2 Specications

Dimensions

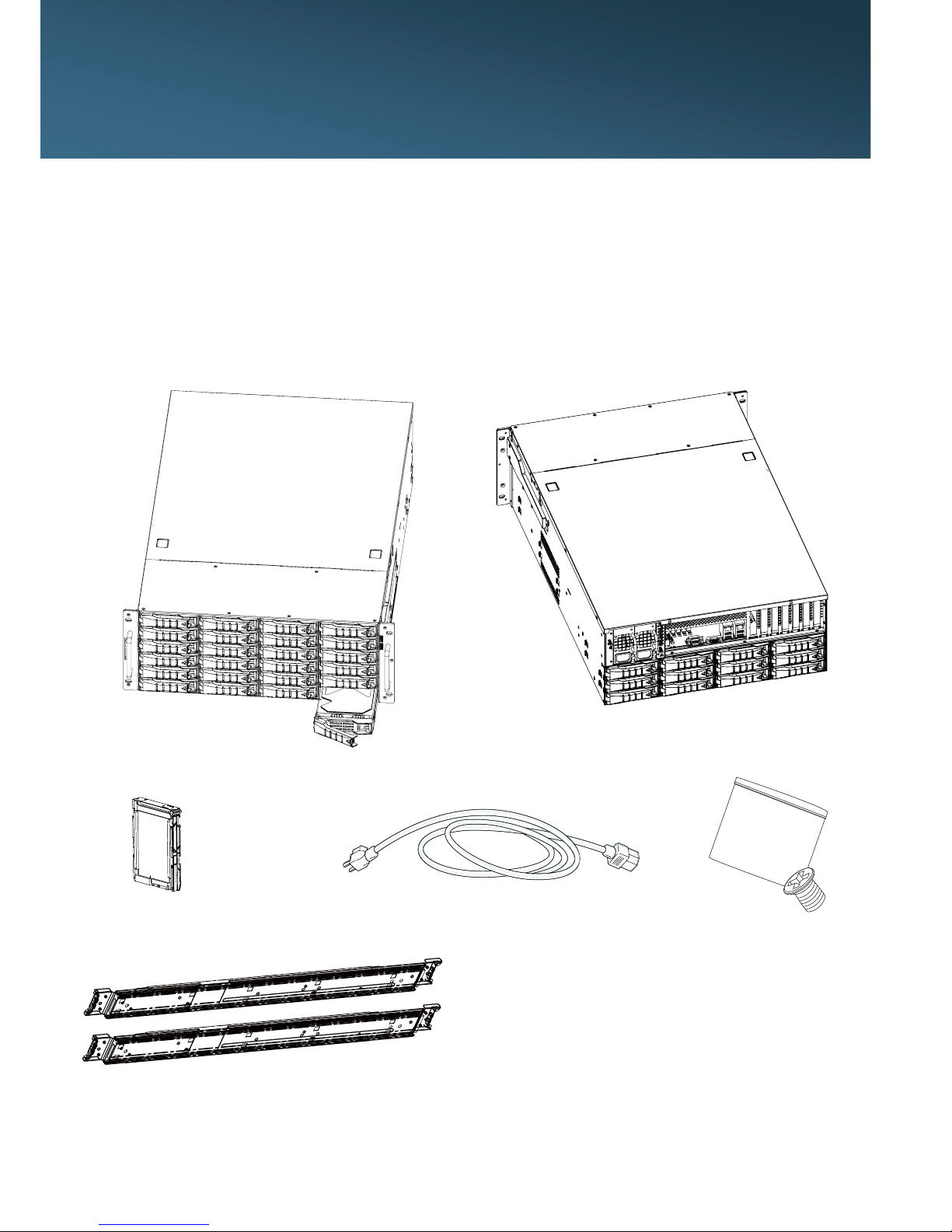

(W x D x H)

(with chassis ears)

mm : 483 x 679 x 173.5

inches : 19 x 26.7 x 6.8

Motherboard AIC Server Board Libra

Processor

Processor

Support

Two Intel® Xeon® Processors E5-2600

v3 and next generation Product Family

QPI Speeds 9.6 GT/s, 8 GT/s, 7.2 GT/s

Socket Type Socket R3 (FCLGA2011-3)

Chipset Support Intel® C612 Chipset

System Memory

• 16 DIMM slots across 8 memory channels

(4 memory channels per CPU; 2DPC)

- 512GB DDR4 2133/1866 RDIMM DRx4

- 128GB DDR4 2133/1866 RDIMM SRx4

- 1024GB DDR4 2133/1866 LRDIMM QRx4

- 2048GB DDR4 2133/1866 LRDIMM 3DS 8Rx4

Front Panel

• Power on/off

• System reset

• 2 x USB 3.0 Type A connectors

LEDs

• Power

• Alert

• LAN

• Drive

Drive Bays

External 3.5" hot swap 36

Internal 2.5” 2

Backplane 1 x 12-port 12Gb SAS backplane with 28-PHY expander and

3 SFF-8643 connectors

Expansion Slots PCIe 3.0 2 x16 + 1 x16 (x8 mode) + 3 x8 (all LP)

System BIOS

BIOS Type

• Insyde UEFI BIOS

• SPI (Serial Peripheral Interface)

FLASH Interface

BIOS

Features

• ACPI

• PXE

• WOL

• AC loss recovery

• IPMI 2.0 KCS

interface

• SMBIOS

• Serial console

redirection

• BIOS Boot

Specication

• BIOS Recovery

Mode

• SRIOV

• iSCSI

• TPM

• PCIe NTB

On-board

Devices

SATA

Built-in SATA controller with RAID support on

Intel® C612 Chipset

8x 7pin SATA connectors

1x M.2 with SATA/PCIe X2 support

IPMI

Aspeed AST2400 Advanced PCIe Graphics &

Remote Management Processor

• Baseboard Management Controller

• Intelligent Platform Interface 2.0 (IPMI 2.0)

• iKVM, Media Redirection, IPMI over LAN,

Serial over LAN

• SMASH Support

Network

Controllers

• Intel® Ethernet Controller X540-BT2 dual

port 10 GbE, 10GBASE-T, PCIe v2.1, x8

(Or Intel® Ethernet Controller I350-AM2,

dual port GbE, PCIe v2.0 (co-lay with

Intel® X540-BT2). MOQ required.)

• Intel® Ethernet Controller I210-AT, single

port GbE controller, PCIe v2.1, 2.5 GT/s, x1

• Intel® Ethernet Network Connection

I217-LM, single port GbE, 1Gbps

• Realtek® RTL8201EL single port 10/100

Mbps Ethernet PHYceiver for dedicated

BMC port

Graphics

Aspeed AST2400 Advanced PCIe Graphics &

Remote Management Processor

• PCIe VGA/2D Controller

• 1920x1200@60Hz 32bpp

Rear I/O

LAN

2 x RJ45

1 x RJ45 (dedicated BMC port)

2 x RJ45 cabled from two internal 2x5 box

pin-header (optional accessory)

USB 2 x USB 3.0 Type A

VGA 1 x DB-15

Serial Port 1 x DB-9

Power Supply 1200W 1+1 redundant PSU 80+ Platinum

• 100-240VAC, 47-63 Hz

System Cooling Middle : 3 x 80x38 PWM hot swap fans

System

Management

• IPMI 2.0

• KVM over IP

• Media redirection

• Temperature, fan, voltage, PSU sensor monitor

• System temperature

• System ID / System fail indicator

• Remote power on/off/reset

• SEL message alarm through mail

• SNMP support

• Intel NM

Environmental

Specications

• Operating temperature : 0° - 35°C

• Operating altitude condition : 0 - 10K feet

• Storage temperature : -20° - 60°C

• System relative humidity : 5% - 95% (38°C)

non-condensing

Gross Weight (w/ PSU & Rail)

kgs : 40.4

lbs : 89

Packaging

Dimensions (W x D x H)

mm : 610 x 920 x 380

inches : 24 x 36.2 x 15

Mounting Standard 26" tool-less slide rail