7

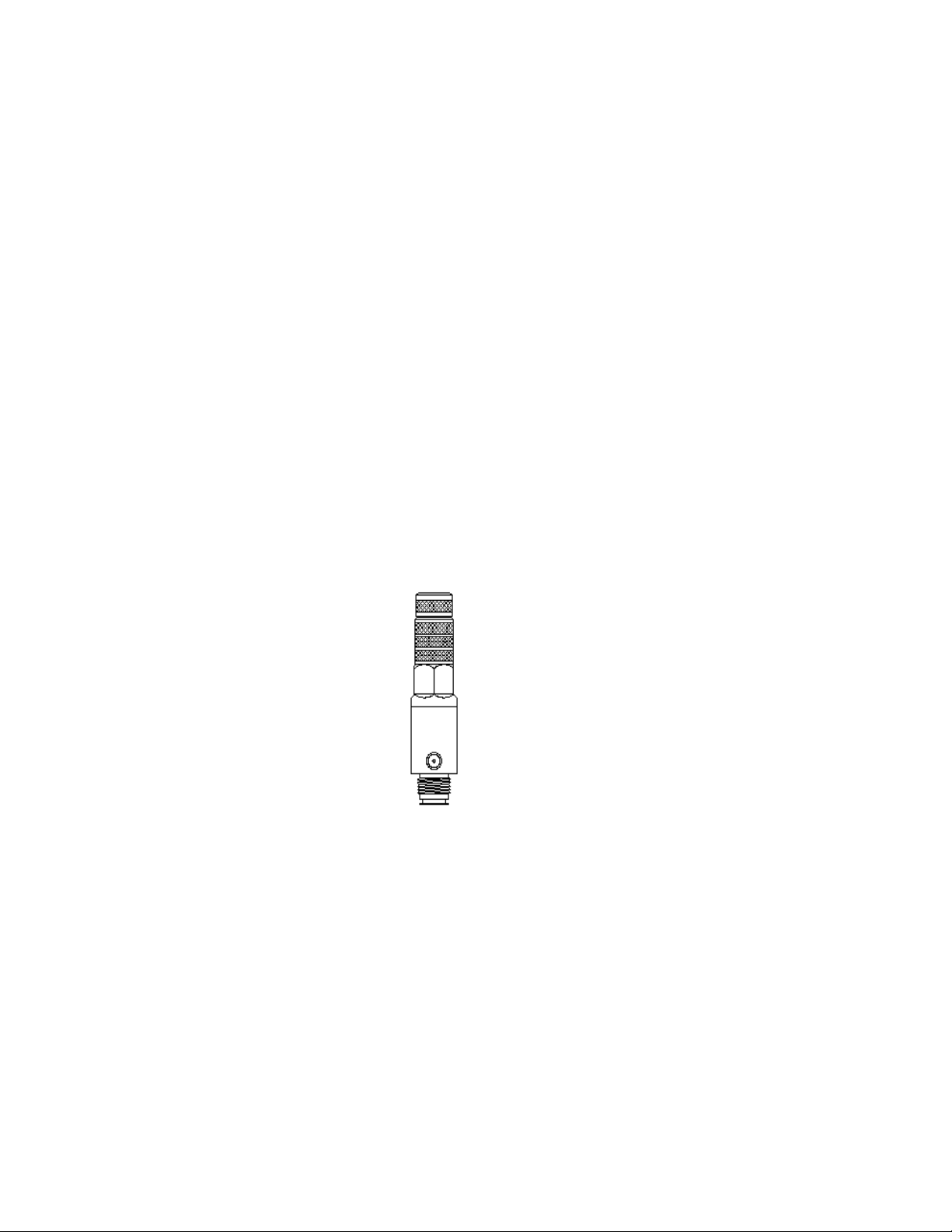

SERVICING THE REGULATOR SEAT AND VALVE PIN

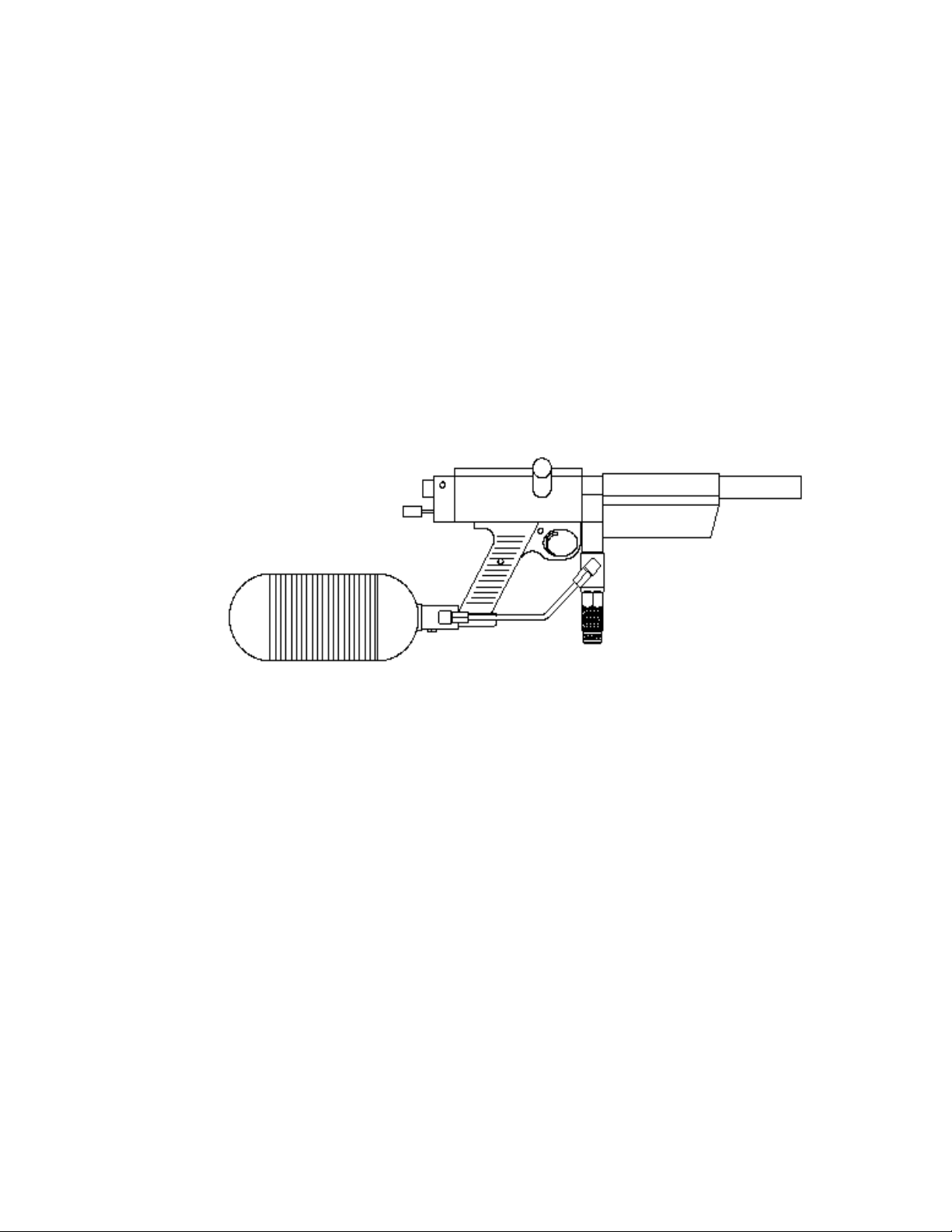

Please refer to the exploded parts diagram shown below when performing maintenance or when

calling in reference to replacement parts.

Your Vigilante™ can be completely disassembled with a 3/16 hex key and a strap or crescent wrench.

Please note: complete disassembly is not required to perform routine maintenance, and should only be done

when servicing the regulator pin and valve seat area.

1. To service these components, it is first necessary to separate the piston housing from the gas

distribution body. Using a strap or crescent wrench and a padded vise, grasp the piston housing and

unscrew it from the gas distribution body.

2. Inspect the regulator seat, valve pin and cone spring for dirt, debris or visible damage.

The sealing face of the valve pin should be clean and free of nicks, scratches and debris. If the valve

pin appears to be marred or bent in should be replace to ensure proper function.

3. The cone spring is a lightly coiled wire spring. It should be free of dirt and debris and should

require a minimal amount of pressure to compress it between your finger tips. If the cone spring

appears to be compressed or has been stretched it should be replaced.

4. The regulator seat can normally be removed from the sealing pocket of the piston housing with

light finger pressure. Should it be necessary to utilize a pick to remove the seat, use caution to

ensure that the sealing pocket does not become scratched or dented. Inspect the regulator seat for

visible obstructions or damage and replace before reassemble. The regulator seat for the Vigilante™

series regulator must be replaced upon each disassembly to ensure proper functioning.

5. When reassembling,

the new regulator seat

should be place in the

sealing pocket of the piston

housing. You will note that

the new seat fits more

loosely than the seat that

you removed. The seating

material used in the

Vigilante™ regulator is

designed to be a

compression fitting and therefore deforms slightly upon proper assembly.

6. Insert the long shaft of the regulator valve pin through the regulator seat into the piston housing.

7. Place the small end of the cone spring on the stud end of the regulator valve pin.

8. Insert the piston housing assembly into the gas distribution body and screw the halves together.

Lubricate the piston housing body o-ring with a light coat of motor oil to prevent the binding of the two

halves.

A properly assembled/tightened regulator should have little to no visible gap between the upper and

lower halves.

Pin S

rin

Pi

Sea