4

3.2 Warranty and liability

Our „General Sales and Delivery Conditions“ apply as a rule.

This is made available to the user at the latest at the time of

contract signing. Warranty and liability claims for personal

and property damage are excluded if they are due to one or

more of the following causes:

• Improper use of the device.

• Improper installation, operation, use, and maintenance of

the pressure equipment.

• Ignoring instructions in the manual with respect to trans-

port, storage, mounting, installation, operation, mainte-

nance, and upgrading of the pressure apparatus.

• Unauthorized alterations to the pressure apparatus.

• Inadequate monitoring of equipment which are subject to

wear.

• Improper repairs.

• Exceeding or falling below the temperature range specified

in the data sheet during operation or during storage.

• Disaster caused by foreign objects and forces of nature.

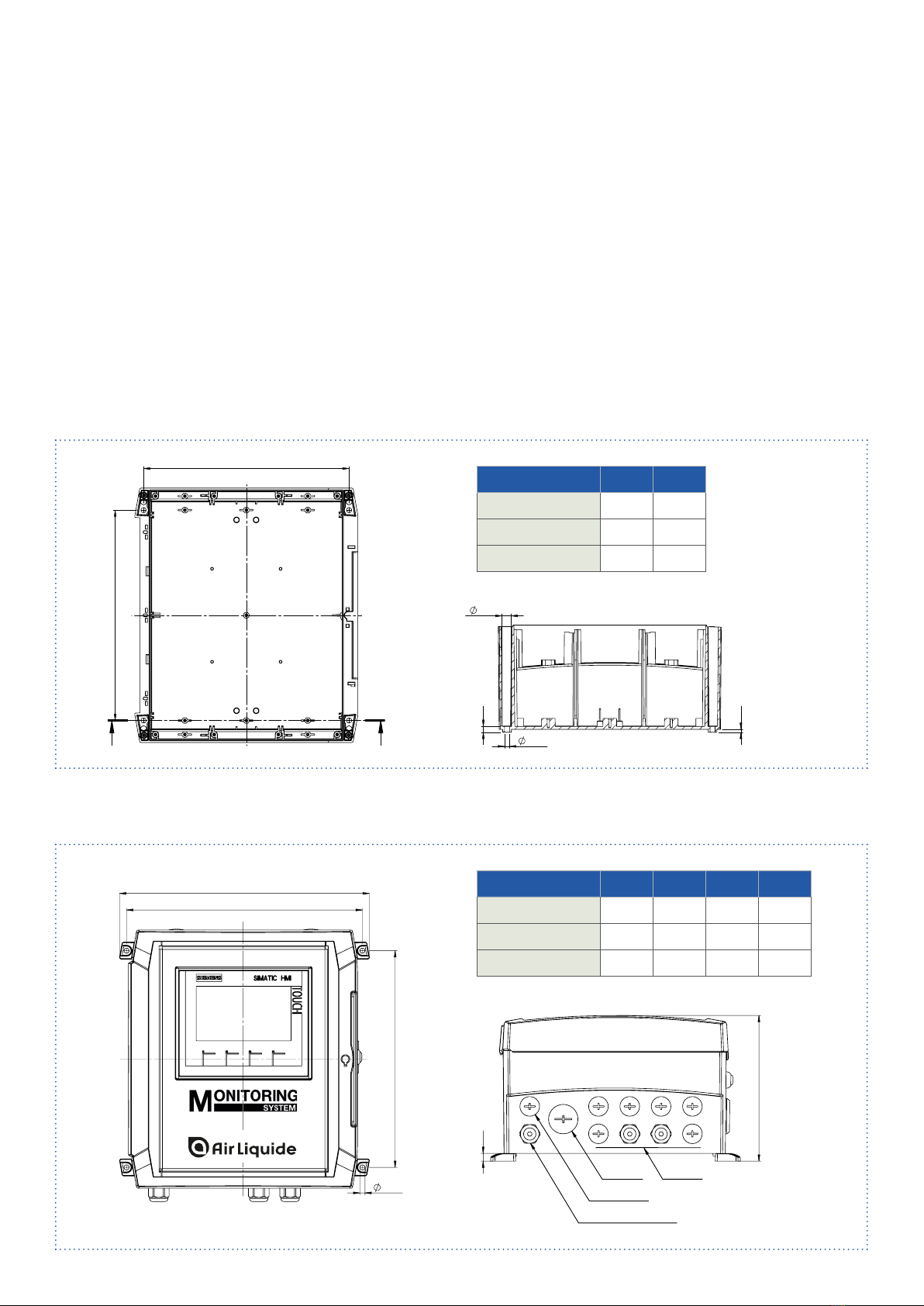

This guide will give you all the necessary information for op-

erating and installing an Air Liquide Monitoring System

ALMS. In this notice, the monitoring system is called the

ALMS.

3.1 Guidelines and general information

• ALMS complies to EU directives and standards for electri-

cal safety and electromagnetic compatibility. Improper use

can result in damage to persons and objects. Improper use,

installation, or operation nullifies any guarantee.

• When used in installations and under environmental condi-

tions requiring higher safety standards, the requirements

and regulations of your country must be observed.

• Always keep the equipment and the ALMS freely accessi-

ble.

• Modifications to the equipment and the connection of ad-

ditional devices fall under the responsibility of the operator.

These steps must be checked and, if necessary, corrected

by the operator.

• Accessories and options are optimally adapted to the de-

vice. Therefore, do not use custom solutions. Any modifica-

tions to the device and connection of auxiliary devices is

the responsibility of the operator and must be checked by

the user.

• For storage and transport, the unit should not be exposed

to extreme temperatures, shock, or vibration.

• Notes and information on operating specifications can be

provided on request.

3 General information