BB15 Series BB30 Series BB50 Series BB75 Series BB100 series BB150 series

Size 19”L X 13”H X 7”D 19”L X 13”H X 7”D 24”L X 17”H X 8.5”D 24”L X 17”H X 8.5”D 26.5”L X 21”H X 9”D 26.5”L X 21”H X 9”D

Weight 12.3 lbs/5.6 kg 19.7 lbs/8.9 kg 26.4 lbs/12 kg 34.2 lbs/15.5 kg 38.8 lbs/17.6 kg 38.8 lbs/17.6 kg

Inlet Size 1/4” industrial

interchange

1/2” industrial

interchange

1/2” industrial

interchange

1/2” industrial

interchange

1/2” industrial

interchange 1” Chicago

No. of Outlets 1 2 standard

3 op onal 46 or single 1/2”

NPT outlet

4-8 or single

1/2” NPT outlet

(3) 1/2” industrial

interchange

Maximum Air

Flow (cfm/bar)

15 scfm @ 110 psi

425 lpm @ 7.6 bar

30 scfm @ 110 psi

850 lpm @ 7.6 bar

50 scfm @ 110 psi

1415 lpm @ 7.6 bar

75 scfm @ 110 psi

2124 lpm @ 7.6 bar

100 scfm @110 psi

2832 lpm @7.6 bar

150 scfm @110 psi

4248 lpm @7.6 bar

Remote

Alarm Signal No Yes Yes Yes Yes Yes

Maximum Inlet

Pressure 150 psi (10.3 bar)

Relief Valve 125 psi (8.6 bar)

Monitoring Inline Con nuous Monitoring of Carbon Monoxide (CO)

Power 9-16 VDC or 115 VAC 50/60 Hz

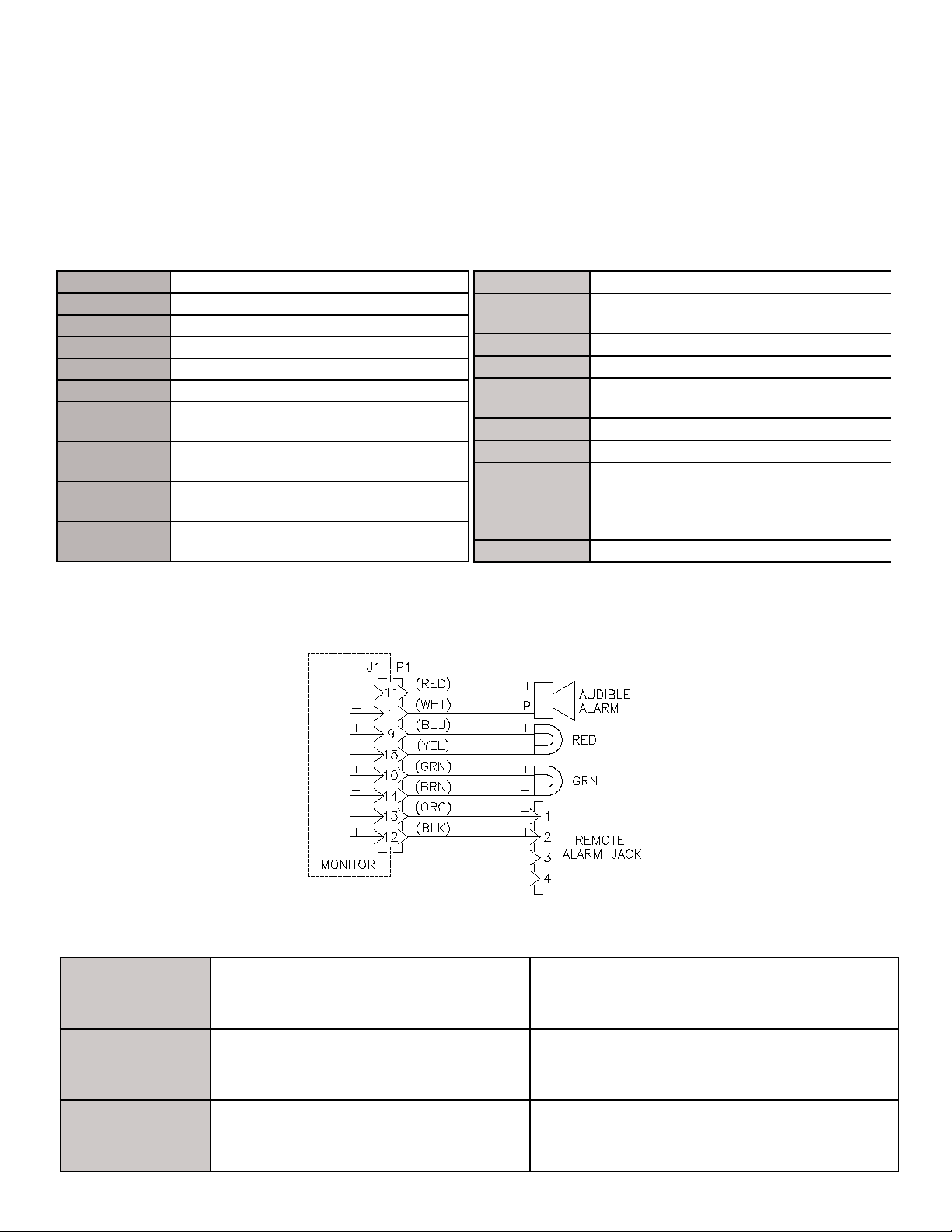

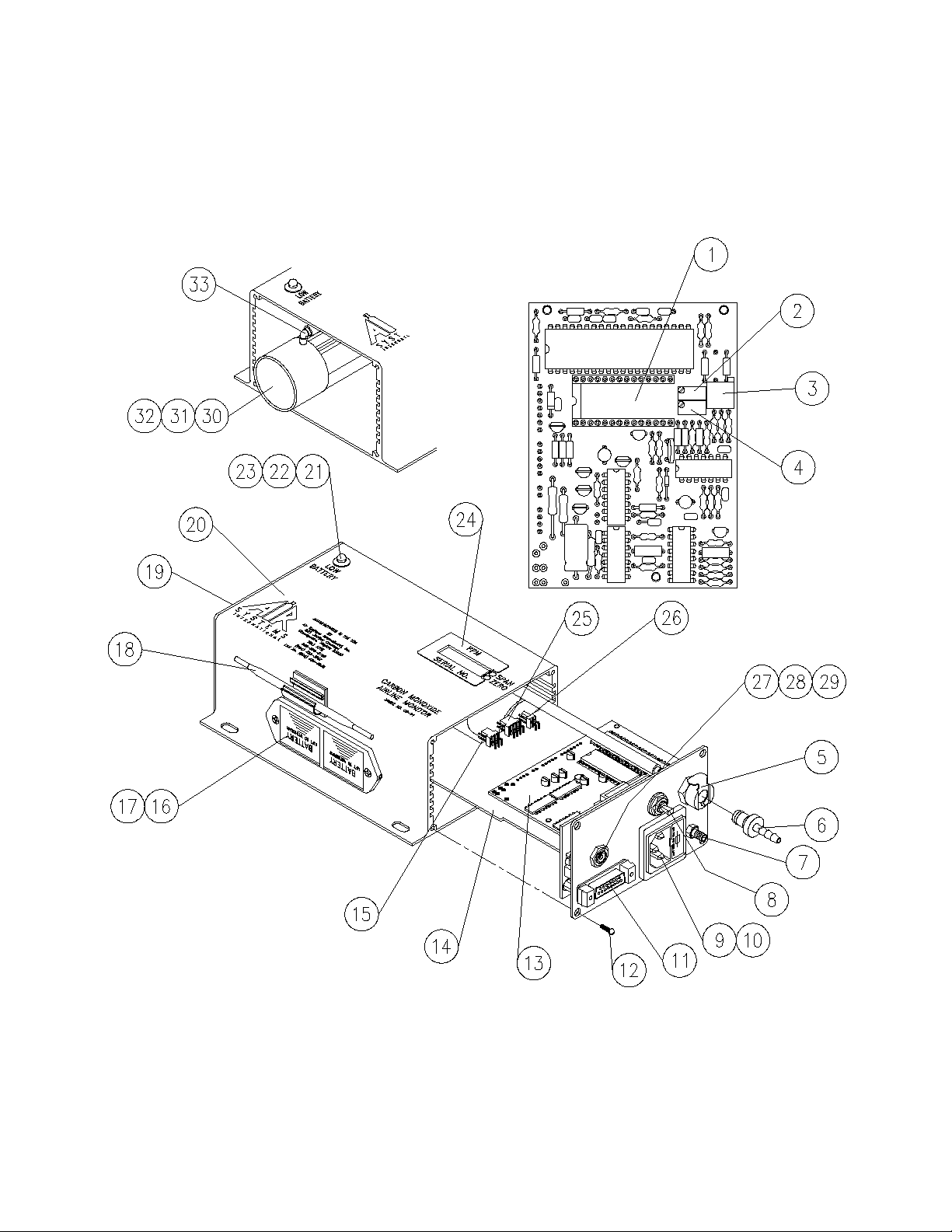

Item # Descripon BB15 BB30 BB50 BB75 BB100 BB150

1Remote Alarm Jack N/A ELJP004 ELJP004 ELJP004 ELJP004 ELJP004

2Remote Alarm Jack Cover N/A ELJP005 ELJP005 ELJP005 ELJP005 ELJP005

3High CO Audible Alarm N/A ELLS004 ELLS004 ELLS004 ELLS004 ELLS004

4 High CO Indicator N/A MONC004 MONC004 MONC004 MONC004 MONC004

5 Clear LED Lens N/A ELDS013 ELDS013 ELDS013 ELDS013 ELDS013

6Normal Operaon Indicator N/A MONC005 MONC005 MONC005 MONC005 MONC005

7Inlet Fing QDH3PL6M QDH5PL8M QDH5PL8M QDH5PL8M QDH5PL8M QDCHI16M

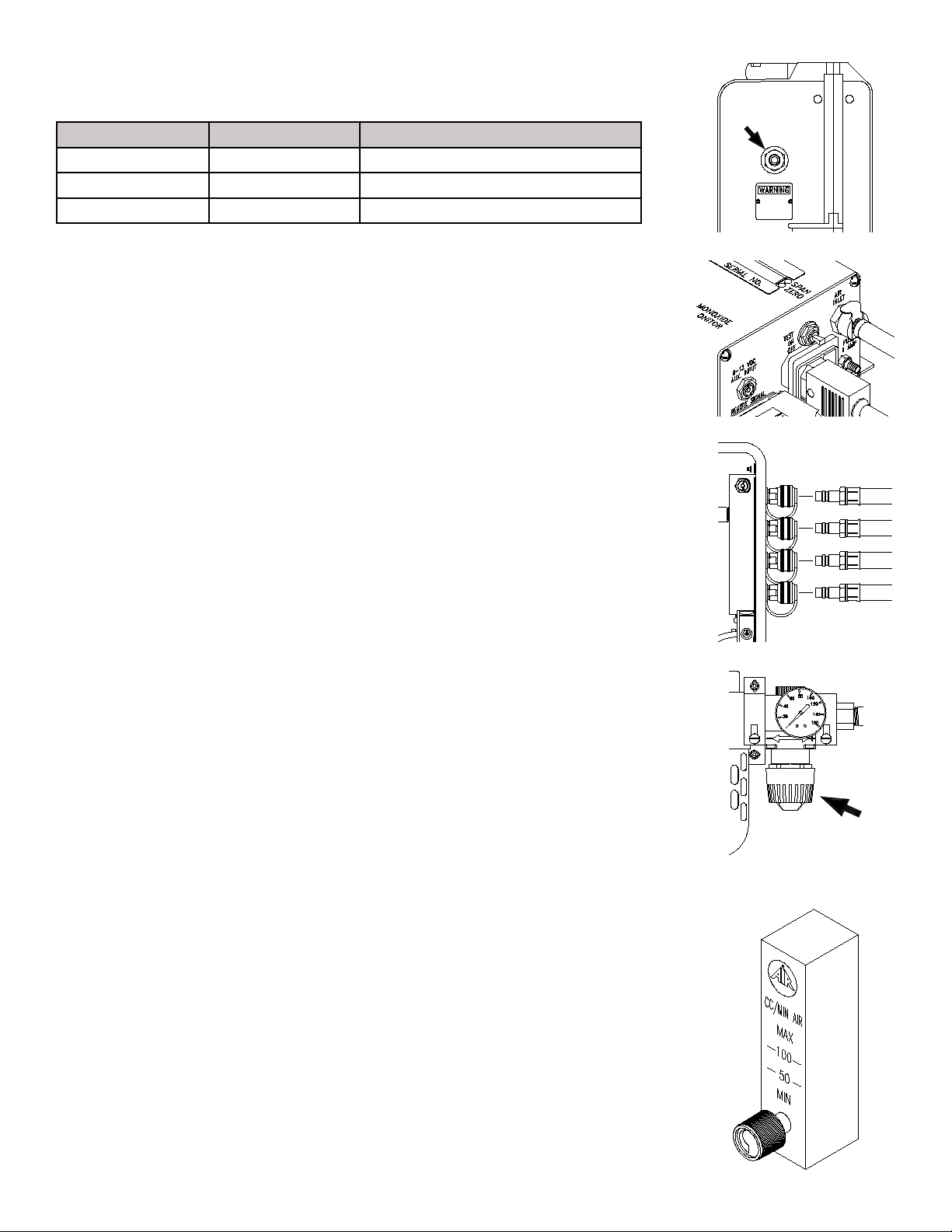

8 Pressure Gauge GA20160B GA20160B GA20160B GA20160B GA20160B N/A

9 Relief Valve VR4125BR VR4125BR VR4125BR VR4125BR VR4125BR VR4125BR

10 Hansen Coupling QDH3SL6M QDH3SL6M QDH3SL6M QDH3SL6M QDH3SL6M QDH5SL12M

10a Schrader Coupling QDSSL6M QDSSL6M QDSSL6M QDSSL6M QDSSL6M N/A

11 Hansen Dust Cap QDH3DCAP QDH3DCAP QDH3DCAP QDH3DCAP QDH3DCAP N/A

11a Schrader Dust Cap QDSDCAP QDSDCAP QDSDCAP QDSDCAP QDSDCAP N/A

12 1st Stage Filter Assembly 15FLTRAW WL251 WL007 WL175 WL066 WL132

13 2nd Stage Filter Assembly 15FLTRCW WL253 WL008 WL177 WL017 WL059S

14 3rd Stage Filter Assembly 15FLTRDW WL255 WL009 WL179 WL018 WL060S

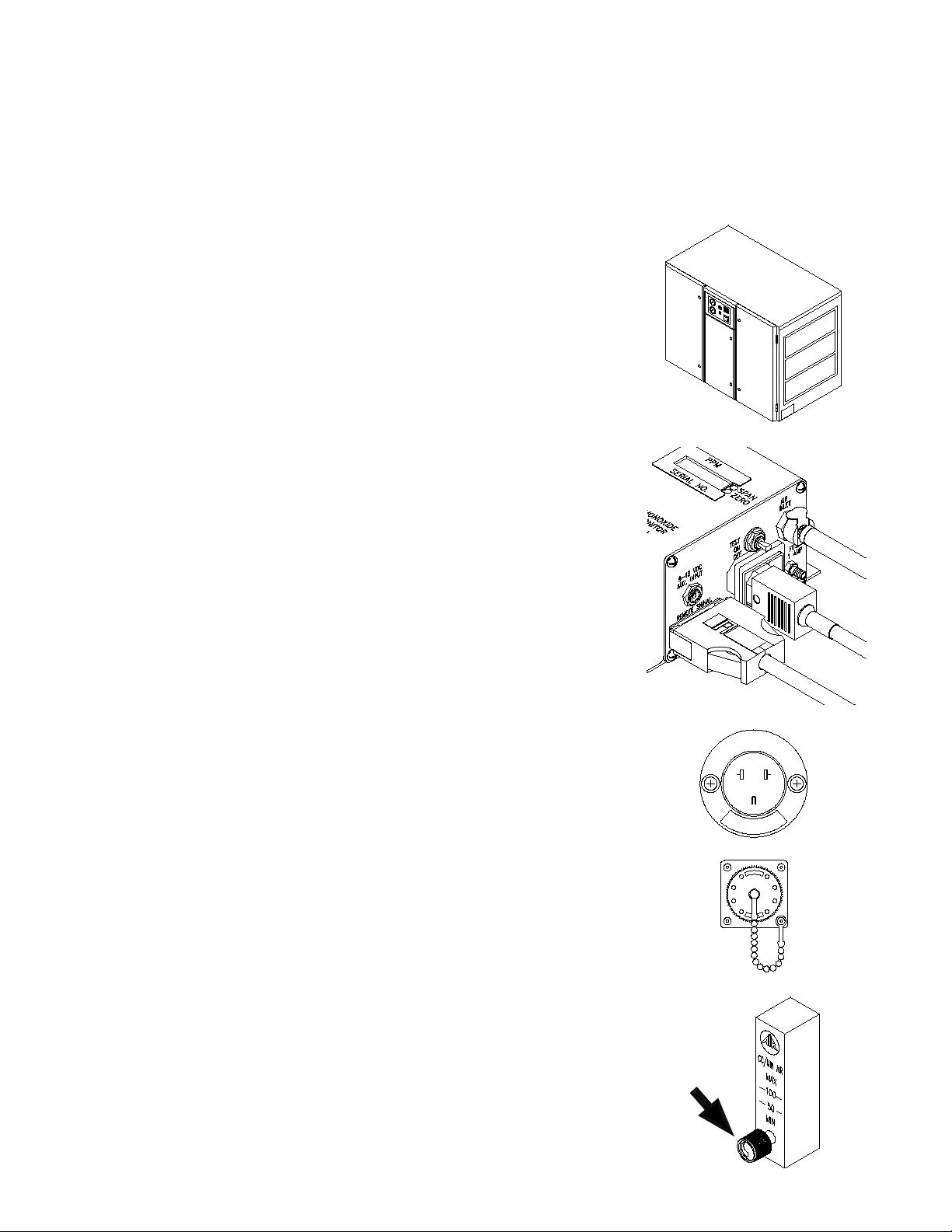

15 Flowmeter WL033NS WL033NS WL033NS WL033NS WL033NS WL033NS

16 Pressure Regulator 15REGW WL257 WL015 WL181 WL015 WL013A

17 Carbon Monoxide Monitor CO-91AB CO-91 CO-91 CO-91 CO-91 CO-91

18 115 VAC Recessed Plug ELJP006 ELJP006 ELJP006 ELJP006 ELJP006 ELJP006

BREATHER BOX™ PARTS IDENTIFICATION

2