10

Shutdown Procedure

1) Make sure all personnel have egressed from the work area.

2) Shut off air source to the box.

3) Remove air pressure from the box by pulling the relief valve ring out.

4) Turn the CO monitor OFF. Do not remove the 9 volt batteries. These are used to maintain a bias voltage to the sensor.

This keeps the sensor ready for immediate use.

5) Disconnect airline hoses.

6) Install dust caps if applicable.

System Maintenance

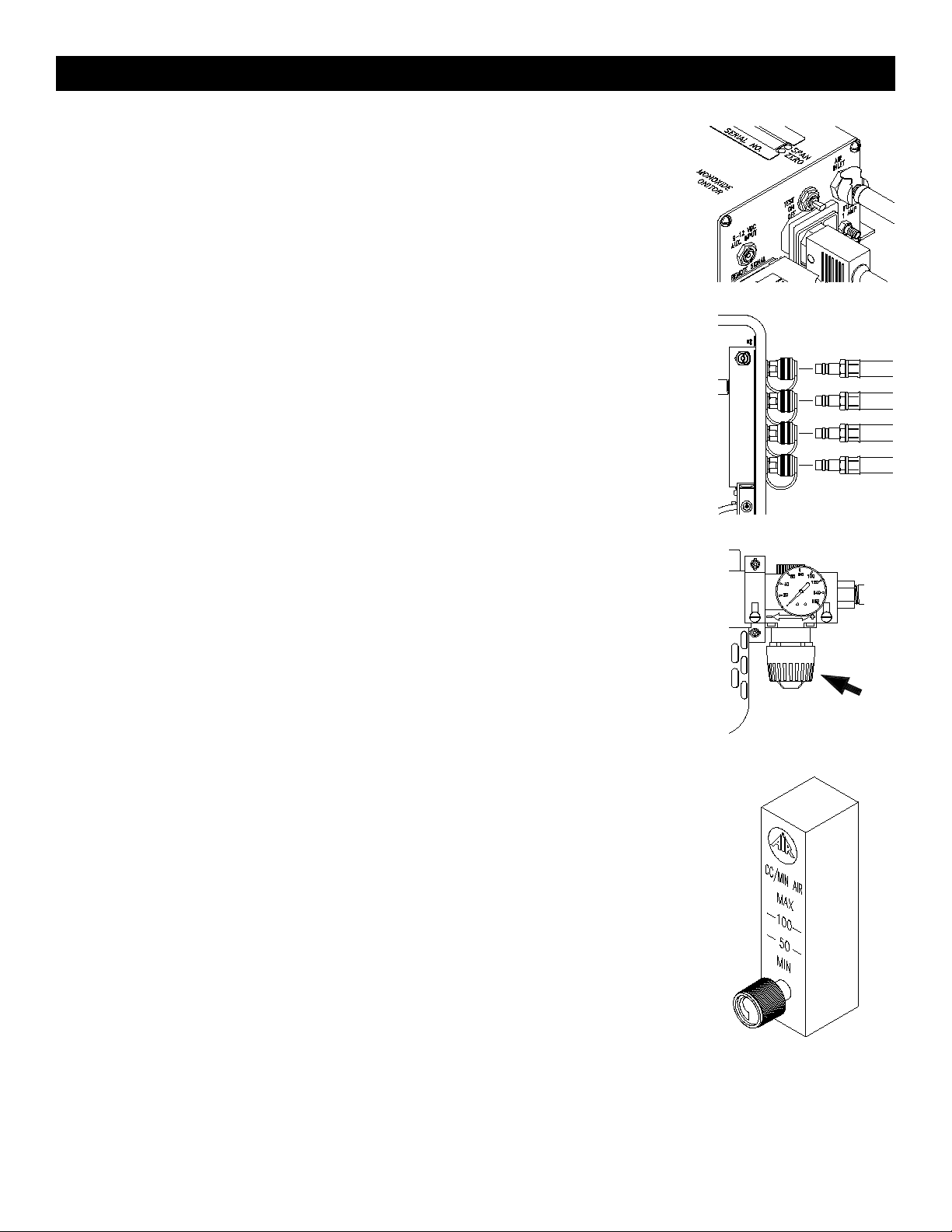

Filter Housing/Bowls: Periodic cleaning of the polycarbonate bowls may become necessary. Remove the auto drains and

clean the bowls with a mild soapy solution. The auto drains may also be cleaned with a mild soapy solution at this time.

Dry and reinstall into the lter housing.

Filter Change: The ltration system consists of lter change indicators which will gradually change from green to orange

when lter life is spent.

Note: Air must be owing through the lters before the lter change indicators will function.

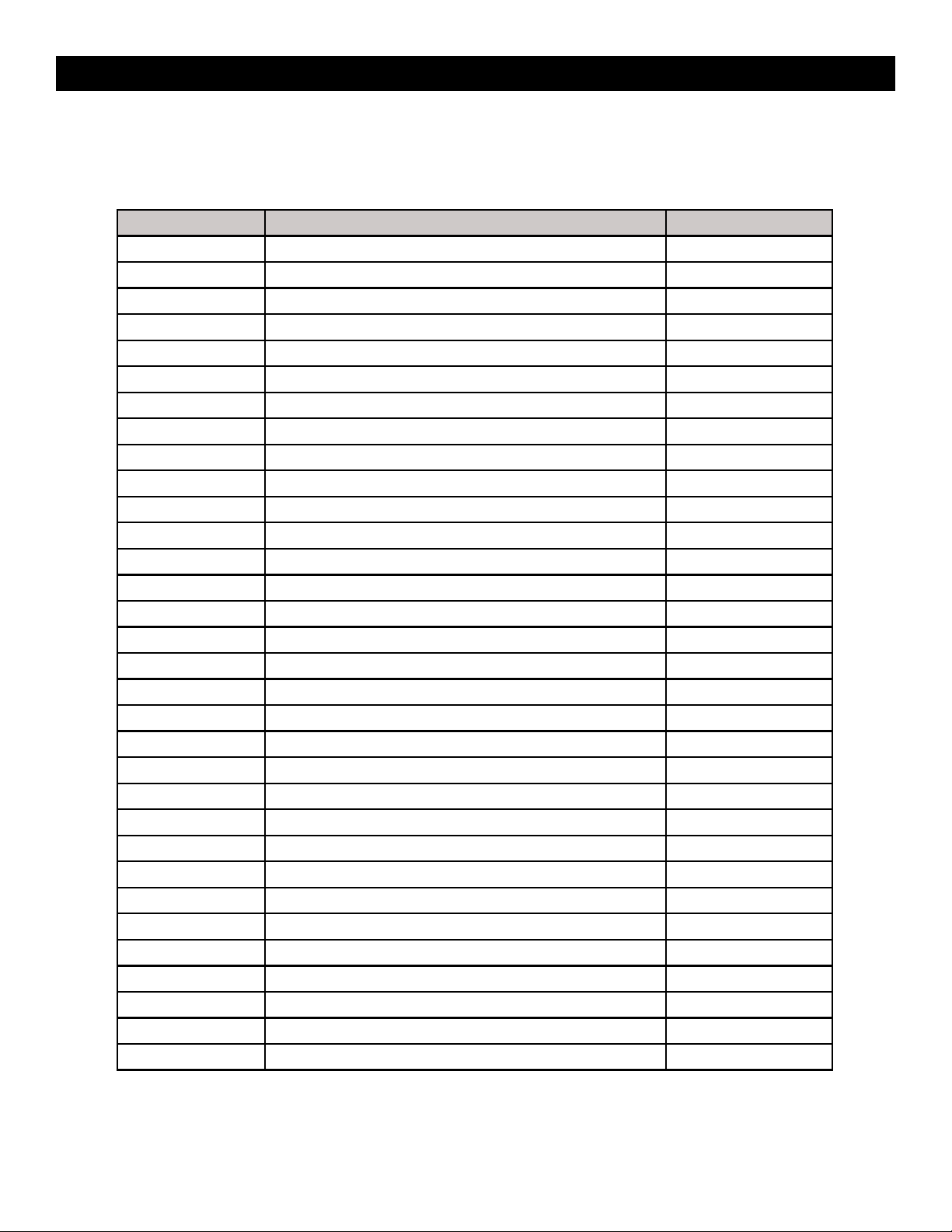

Calibration: Monitor calibration should be done monthly or whenever the reading may be questionable. A calibration date

sticker should be af xed for future reference. To obtain an accurate calibration, we recommend the use of Air Systems’

calibration kits.

Part Number:

BBK-10 Canadian calibration kit for CO monitor; 10ppm CO, zero air, regulator and case - 17 liter size.

BBK-20 Calibration kit for CO monitor; 20ppm CO, zero air, regulator and case - 17 liter size.

BBK-20103 Calibration kit for CO monitor; 20ppm CO, zero air, regulator and case - 103 liter size.

DECAL085CD Calibration decal card, contains 14 calibration decals.

To assure sensor accuracy, calibration of monitor is required. If you cannot obtain an accurate calibration, sensor replace-

ment may be necessary. Consult Repair Service Department before ordering.

Part Number:

CO-91NS Replacement CO sensor

CAUTION: Always depressurize the system before performing service.

Monitor Baery Replacement

These batteries provide the required continuous bias voltage to the CO sensor and power the monitor in the event of AC

power loss. If AC and DC power are removed for a period of 2 hours or more, a 1 hour restabilization period is required

as eratic readings may occur.

Battery Replacement: Replace 9 volt batteries when the amber “Low Battery” light illuminates. If the monitor is not used

for 90 days, check the 9 volt batteries and replace if necessary.