Page

3Air Techniques, Inc.

Contents

Important Information

1� Notes on this documentation � � � � � � � � � � � � � � � � 4

1�1 Warnings and symbols � � � � � � � � � � � � � � � � 4

1�2 Notes concerning trade marks, brand names

etc� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�3 Further documentation � � � � � � � � � � � � � � � � 4

2� Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2�1 Intended Use � � � � � � � � � � � � � � � � � � � � � � � 4

2�2 Incorrect Usage � � � � � � � � � � � � � � � � � � � � � 5

2�3 General safety notes � � � � � � � � � � � � � � � � � � 5

2�4 Qualified staff � � � � � � � � � � � � � � � � � � � � � � 5

2�5 Protection from electric shock � � � � � � � � � � � 5

2�6 Use original parts � � � � � � � � � � � � � � � � � � � � 5

2�7 Transport � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�8 Disposal � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Product description

3� Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Delivery contents � � � � � � � � � � � � � � � � � � � � 6

3�2 Accessories� � � � � � � � � � � � � � � � � � � � � � � � � �

3�3 Working parts and spare parts � � � � � � � � � � � 6

4� Technical data � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1 Ambient conditions � � � � � � � � � � � � � � � � � � � 8

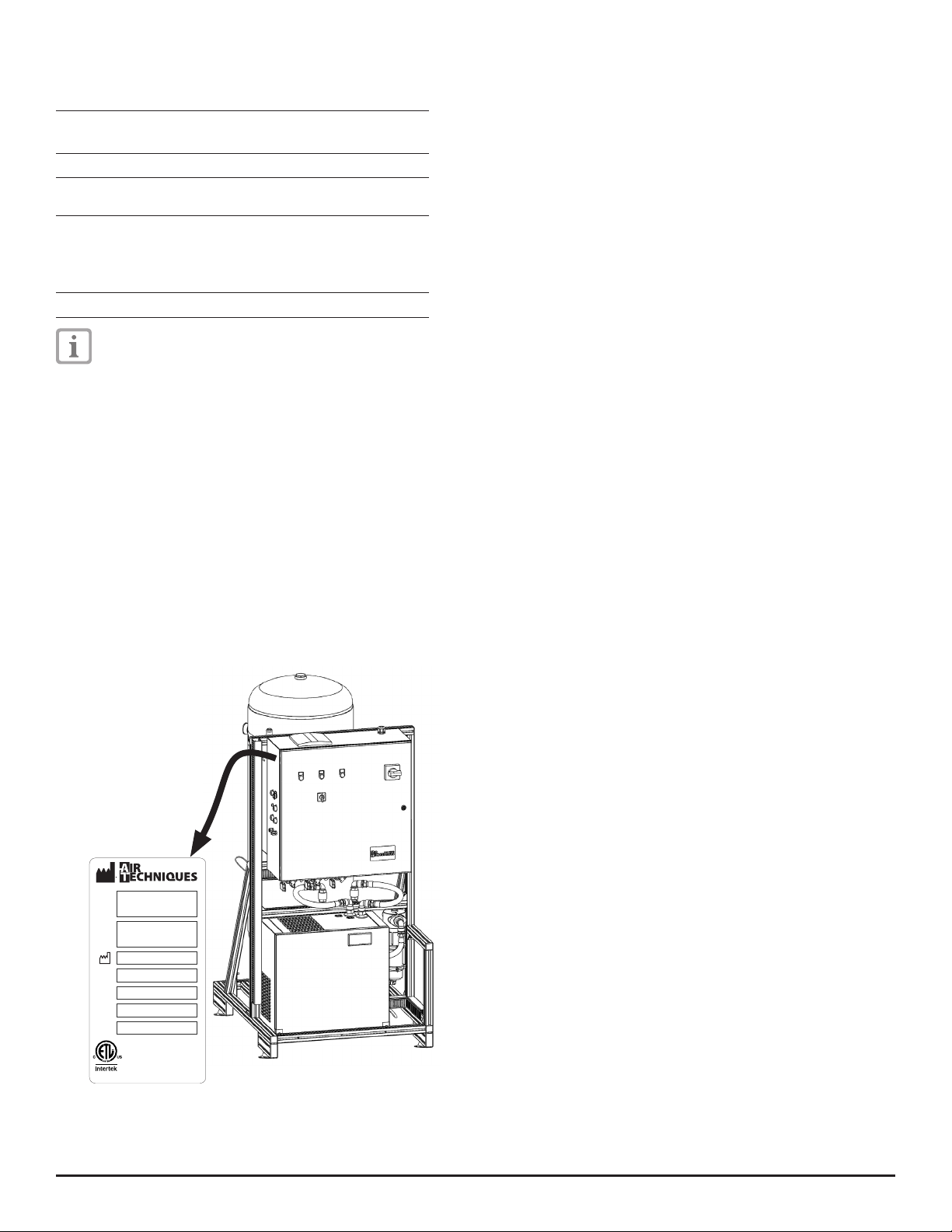

4�2 Model identification plate � � � � � � � � � � � � � � 8

4�3 Declaration of conformity � � � � � � � � � � � � � � 8

5� Function � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

5�1 Start operation � � � � � � � � � � � � � � � � � � � � � 11

5�2 Normal operation � � � � � � � � � � � � � � � � � � � 11

5�3 Emergency mode � � � � � � � � � � � � � � � � � � � 11

Mounting

6� General Notes � � � � � � � � � � � � � � � � � � � � � � � � � 12

6�1 Compressed air system requirements � � � � � 12

6�2 Set up in medical supply equipment � � � � � � 12

7� Transport � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

8� Set-up � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

8�1 Set-up location � � � � � � � � � � � � � � � � � � � � � 12

8�2 Module layout � � � � � � � � � � � � � � � � � � � � � 12

8�3 Set up and secure modules � � � � � � � � � � � � 12

9� Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

9�1 Connect the compressed air connection to

the cyclone separator � � � � � � � � � � � � � � � � 13

9�2 Connect the pressure tank to the com-

pressed air supply net � � � � � � � � � � � � � � � � 13

9�3 Connect the condensate drain outlet to the

waste water system � � � � � � � � � � � � � � � � � � 14

10 Electrical Connection � � � � � � � � � � � � � � � � � � � � 14

10�1 Electrical connection and safety � � � � � � 14

10�2 Connecting modules � � � � � � � � � � � � � � 14

10�3 Connection line dimensions � � � � � � � � � 14

10�4 Match motor protection switch to net-

work frequency � � � � � � � � � � � � � � � � � � 14

10�5 Connect control unit to the mains power

supply � � � � � � � � � � � � � � � � � � � � � � � � 14

11 Initial start-up � � � � � � � � � � � � � � � � � � � � � � � � � 15

11�1 Switching on compressed air station � � � 15

11�2 Choose operational mode � � � � � � � � � � 15

11�3 Document acceptance test � � � � � � � � � � 15

11�4 Measuring dew point (optional) � � � � � � � 15

Use

12 Activating emergency mode � � � � � � � � � � � � � � � 16

13 Decoupling a single compressor generator � � � � � 16

14 Fault rectification � � � � � � � � � � � � � � � � � � � � � � � 16

15 Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � 17

15�1 Maintenance plan � � � � � � � � � � � � � � � � 17

15�2 Maintenance � � � � � � � � � � � � � � � � � � � � 18

Trouble-shooting

16 Tips for Operators and Technicians � � � � � � � � � � 19

16�1 Faults that appear on the display panel � 19

16�2 Further messages at display panel � � � � � 20

Warranty� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Warranty registration � � � � � � � � � � � � � � � � � � � � � � � 23