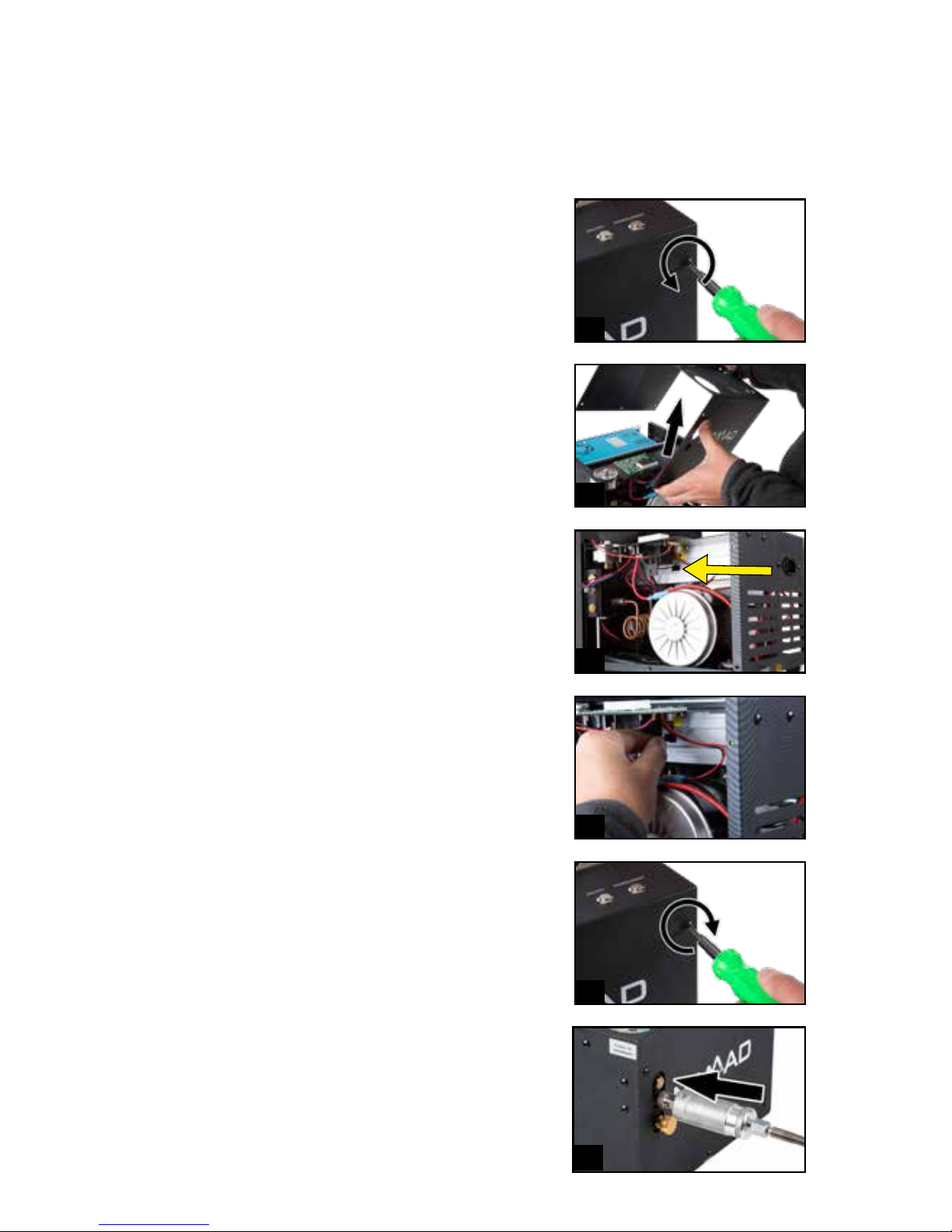

1) Plug the power cord into the Nomad II (g. 1). DO NOT

plug the three prong connector into an active wall outlet yet.

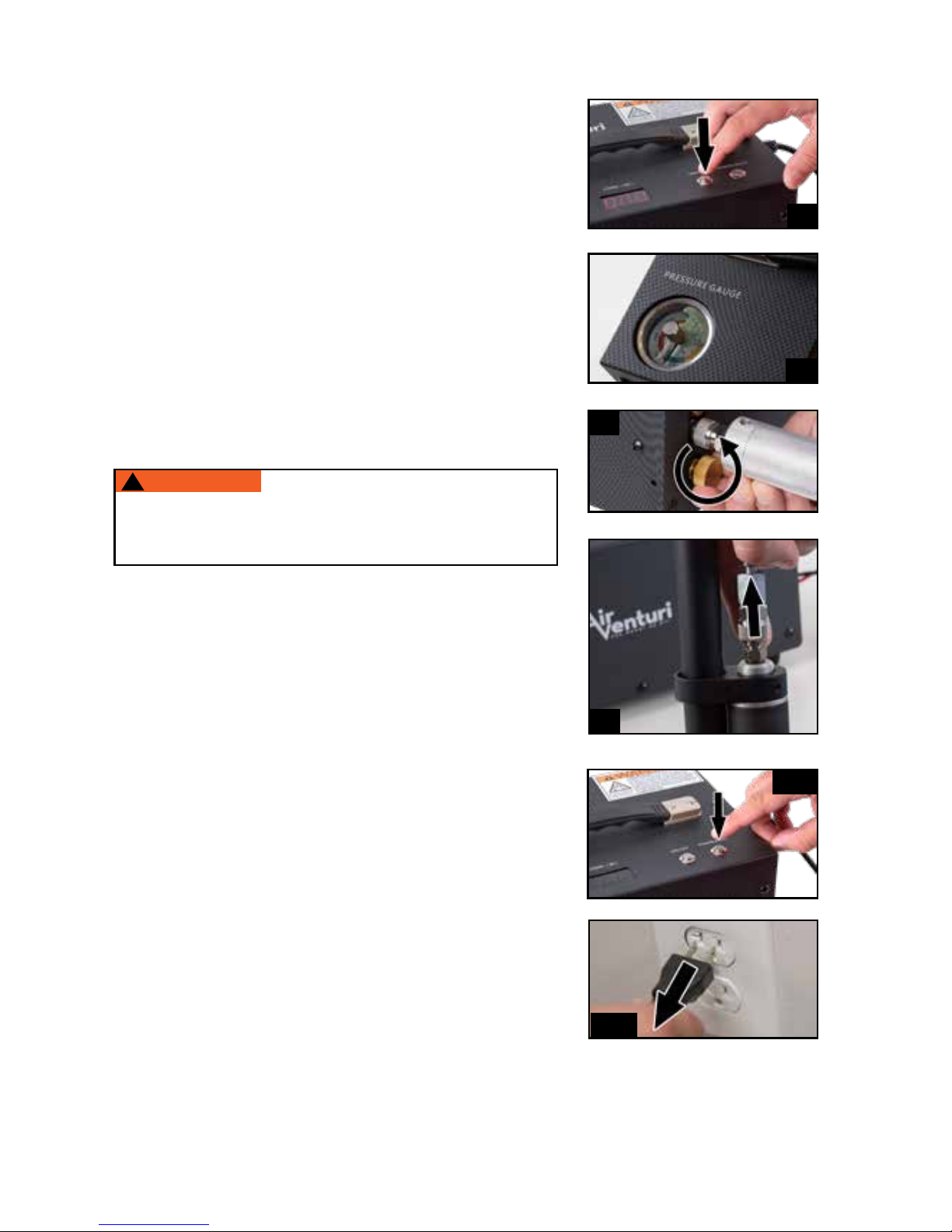

2) Plug the 110V three prong connector into your wall outlet

(g. 2). Once plugged in, the fan on the power converter

will turn on. The compressor fans and LOAD gauge will not

come on yet.

NOTE: If connecting to a 220V outlet, an outlet adapter will be necessary to

use the included power cord.

3) Set the desired ll pressure via the dial on the top of the

pressure gauge (g. 3).

4) Make sure the connection between the female quick

disconnect on the hose and the male connection on the

compressor are tight (g. 4).

5) Close the bleed/pressure release valve by turning it

clockwise until it is tight (g. 5).

6) On the underside of the unit, locate the “Moisture Release

Valve” and turn clockwise (g. 6) until tight to close it.

7) Connect the output hose to the device you wish to ll via

the female quick disconnect tting (g. 7).

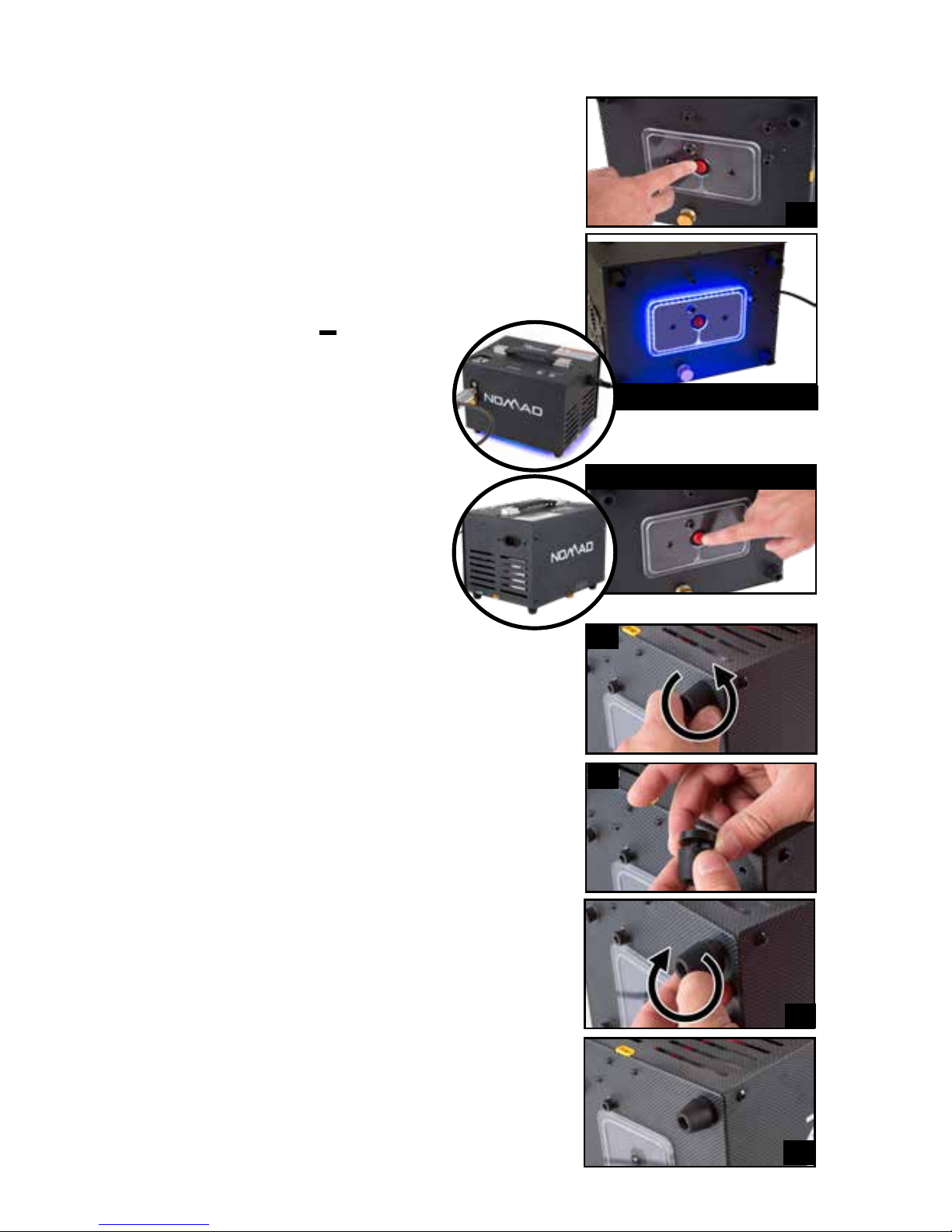

PLEASE NOTE: If you are lling a PCP airgun from empty, you may need to

cock the gun before starting the ll process. Consult the owner's manual of

your airgun for further instructions.

8) Once these steps are complete, depress the POWER/

RESET button. The LOAD gauge will illuminate and the

compressor fans will begin to run (g. 8).

5

Operation Instruction: 110V or 220V outlet

1

2

4

5

© Air Venturi®2018 / www.airventuri.com / 216-292-2570

CAUTION:

Always check and make sure the collar

on the female quick disconnect is in the forward position

and secure on the male tting you are connecting it to.

It is recommended that you check the connection by

attempting to pull the female and male ends apart while

the collar on the female tting is in the forward position.

3

6

7

8

DO NOT OVERFILL AIR

CYLINDERS OR AIR GUN

TANKS, AS THIS CAN CAUSE SERIOUS INJURY OR

DEATH. NEVER SET THE OUTPUT PRESSURE/AUTO

SHUT OFF ABOVE 4500 PSI (310 BAR).

WARNING

!

!

CAUTION:

Always check and make sure the collar

on the female quick disconnect is in the forward position

and secure on the male tting you are connecting it to. It is

recommended that you check the connection by attempting

to pull the female and male ends apart while the collar on

the female tting is in the forward position.

!