3

INTRODUCTION

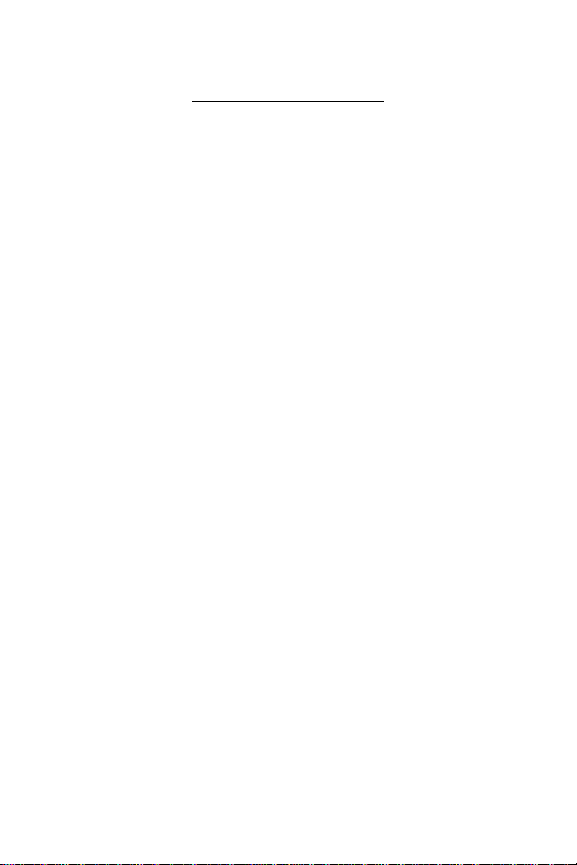

Finally, a vise as fast and versatile as modern

machining.

Welcome to the cutting edge of vise technology.

We know you won’t be disappointed with the

speed and agility this vise will bring to your

operations. The ability to swap jaws in mere

seconds will give you an unmatched capability

to pivot to market demands, while the push

button or electronic open/close feature will

shave minutes off your cycle times and give you

the consistency you demand.

Thank you for trusting our product to create

yours.

OUR MISSION

Here at AVW, we are determined to employ the

most efficient processes we can conceive. Few

things limit modern machining like changing jaws

on your vise. Air Vise was forged from a desire to

both simplify and streamline these inefficiencies

in today’s machining practices.

We are the customer. We know the need, we

know the job, and we know the cost. Our

business is to develop a relationship with you, to

share what helps us succeed in this industry.