2

Table of Contents

About LoadMaxx for Hendrickson Suspensions.........................1

About Installation.............................................................................1

Overview..........................................................................................1

Tools Required.................................................................................2

Optional Tools................................................................................2

Installing the Steer Axle Sensor Bracket......................................3

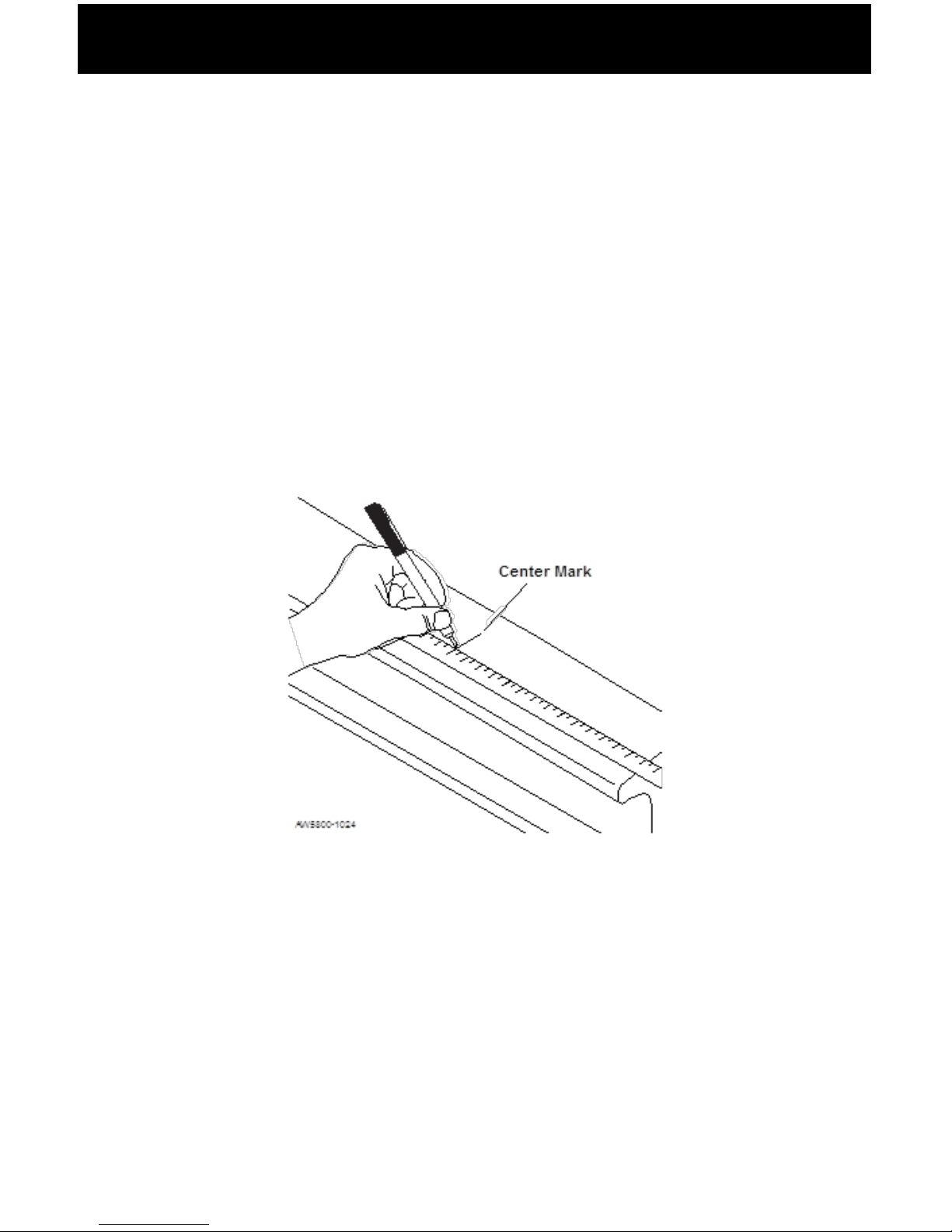

Preparing the Steer Axle Sensor Brackets...............................3

Welding the Bracket......................................................................6

Adding a Protective Spray Paint Coating..................................7

Installing the Drive Axle Sensor Bracket......................................8

Assembling the Bracket to the Jig.............................................8

J-Bracket Placement and Surface Preparation......................10

Welding the J-Bracket.................................................................12

Routing Cables...............................................................................13

Installing the ComLink and Display.............................................14

Preparing the Cab Display for Installation...............................14

Installing the Cab Display...........................................................14

Mounting the ComLink...............................................................15

ConnectingCables.........................................................................16

Power and Ground Table...........................................................16

Securing Cables and Reassembling the Dash......................16