ZZ-PIL

Rev. B 12/5/2017 Page 7

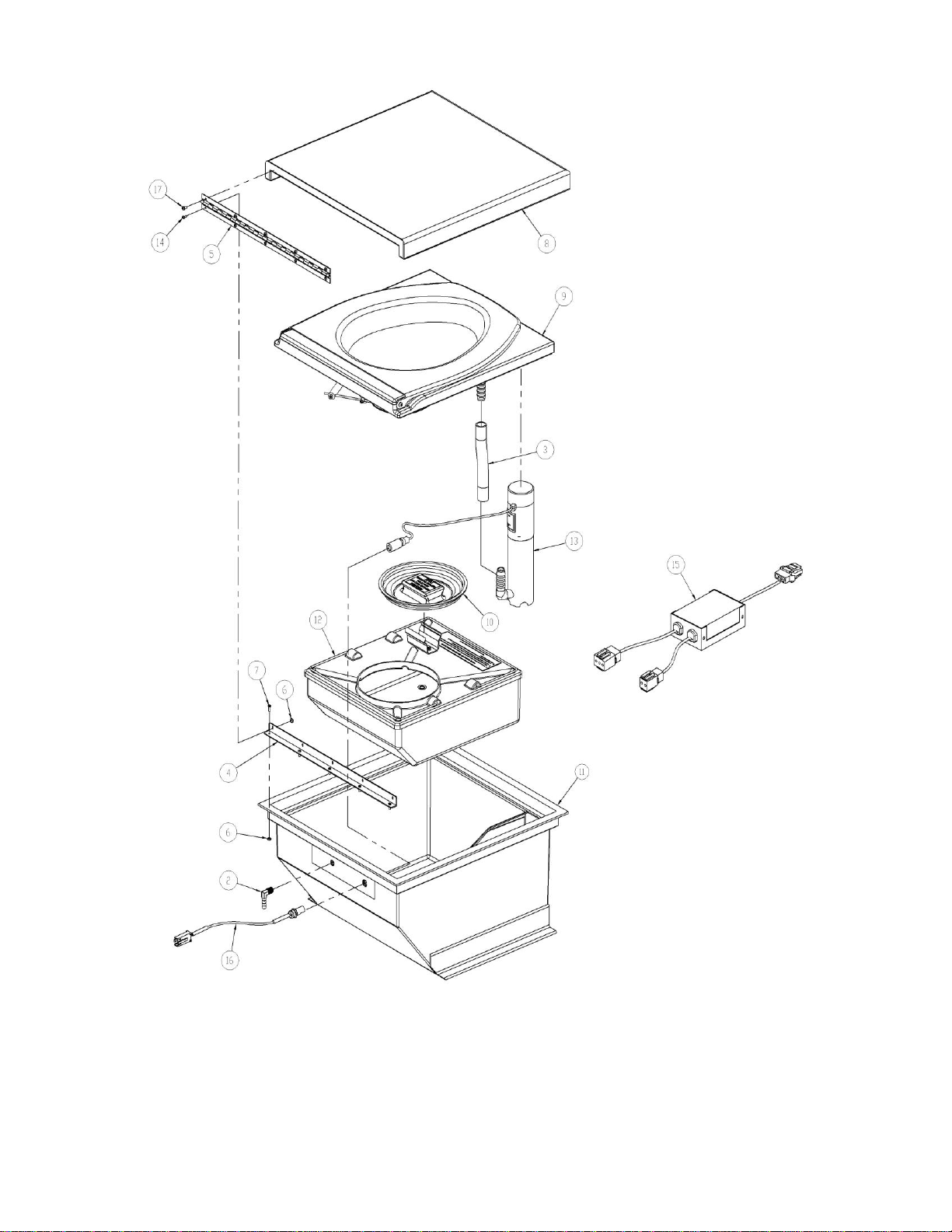

4. Remove screw(s) holding wire clamp (P/N N-2). Remove clamp(s) from wire and save for

reinstallation later.

5. Remove pump from bowl assembly by pulling straight up and rocking back and forth. Note: There

is a sealant/adhesive or double-faced foam tape in the pump cavity for retention. The hose will also

hinder removal and it may be easier to cut the hose and replace it with a new one.

6. Remove hose from bowl fitting.

7. Clean all sealant/adhesive or foam tape from the cavity.

8. Lubricate new hose on the interior of each end with silicone grease and install it on the bowl fitting

by pressing straight down.

9. Place a small amount of sealant or double-faced foam tape in the pump cavity. Ensure the small

hole in the side of the cavity is not covered.

10. Place the new pump into the cavity and align the hose with the pump barb fitting. Check that the

two fittings are aligned.

11. Press the pump into the cavity and onto the hose with firm pressure straight down. Note: The pump

power wire outlet should come within approximately 3/16” of the bowl surface.

12. Replace the wire clamp(s) (P/N N-2) to their original location(s).

13. Lubricate the plug and socket with electrical silicone grease and connect.

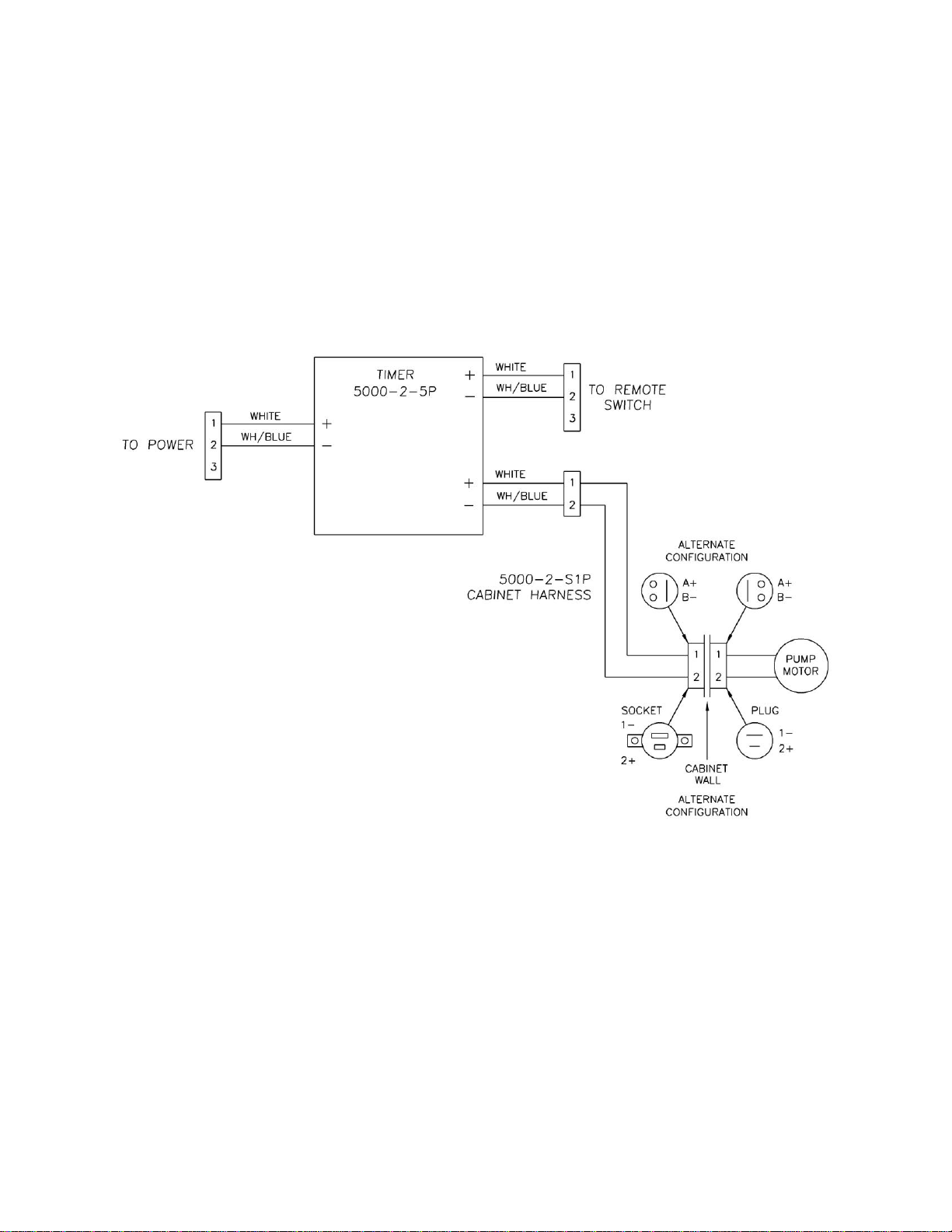

Remove and replace pump power wire connector:

1. Remove the screws that attach the socket to the cabinet then cut wire and discard socket and

connector.

2. Install replacement socket, seal connector wire posts with silicone sealant and install pins in

connector to ensure correct polarity and correct pin placement.

3. To replace pump power wire plug, cut wire as close as possible to connector. Strip wire and solder

to new connector plug posts. Ensure positive wire (white) goes to narrow blade and negative wire

(white w/blue stripe) goes to the wide blade.

4. For units that have a neoprene connector: The socket portion in the cabinet can be removed by

grasping the inner portion and twisting the socket as inward pressure is exerted. Cut off the

connector and replace with a new socket and wire assembly. Insert pins in the connector housing.

5. Replacement of the pump plug pins requires special tools not normally available in the field.

TOILET FUNCTIONAL TEST:

1. Fill reservoir to “Fill to Here” line.

2. Check that pump power wire plug is plugged into socket on rear wall of cabinet.

3. Check that timer is connected to aircraft power, pump power wire and to flush switch.

4. Depress and release flush button. Observe that flushing action continues for approximately 1

second. (There are approximately 10 –13 flushes available in the reservoir.)