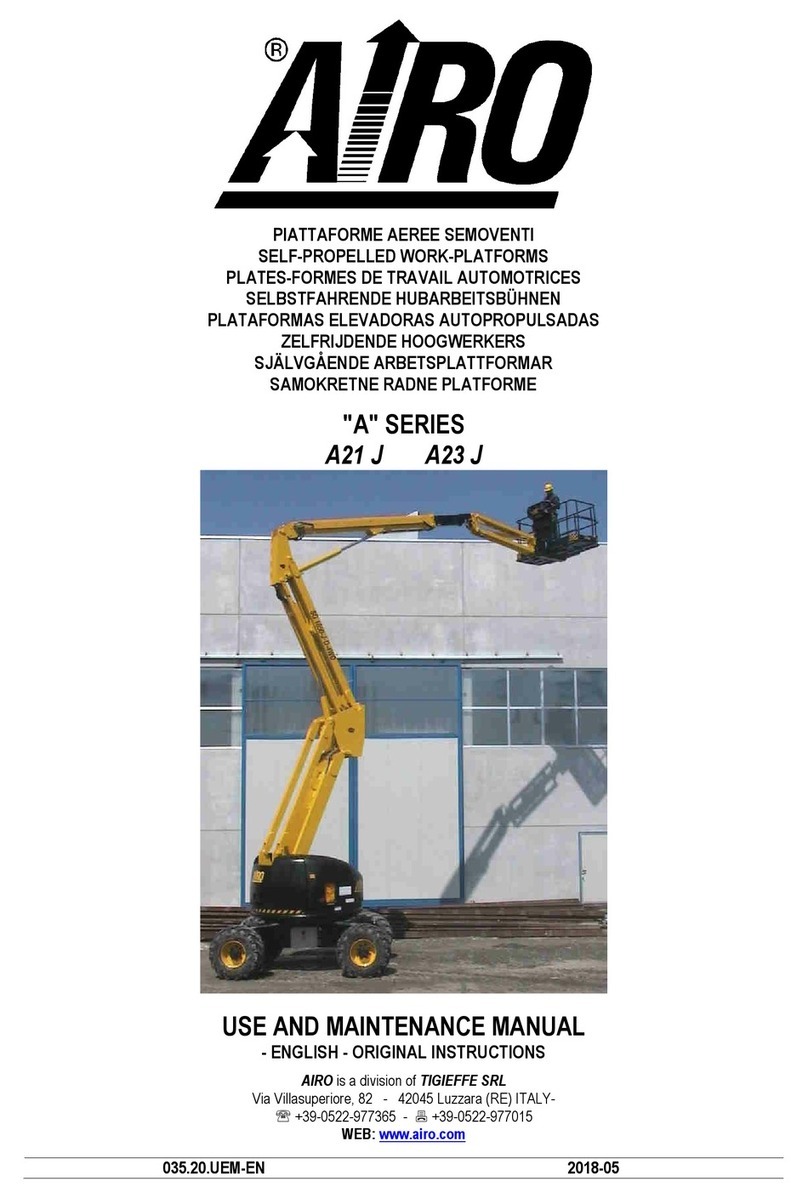

Tigieffe thanks you for purchasing a product of its range, and invites you to read this manual. Here you can find all the

necessary information for a correct use of the purchased machine. Therefore, you are advised to follow the instructions carefully

and to read the manual thoroughly. The manual should be kept in a suitable place where no damage can occur to it. The

content of this manual may be modified without prior notice and further obligations in order to add changes and improvements

to the units already delivered. No reproduction or translation may take place without the written permission of the owner.

CONTENTS

1. INTRODUCTION ....................................................................................................................................................................5

1.1. Legal aspects..................................................................................................................................................................5

1.1.1. Delivery of the machine ..........................................................................................................................................5

1.1.2. Declaration of commissioning, first check, further periodical checks and transfers of ownership...........................5

1.1.2.1. Declaration of commissioning and first check.....................................................................................................5

1.1.2.2. Further periodical checks....................................................................................................................................6

1.1.2.3. Transfers of ownership .......................................................................................................................................6

1.1.3. Operators training and information .........................................................................................................................6

1.2. Tests performed before delivery .....................................................................................................................................6

1.3. Intended use...................................................................................................................................................................6

1.3.1. Leaving at height.....................................................................................................................................................7

1.4. Description of the machine .............................................................................................................................................7

1.5. Control panels.................................................................................................................................................................8

1.6. Power supply ..................................................................................................................................................................8

1.7. Machine life, demolition and decommissioning...............................................................................................................8

1.8. Identification....................................................................................................................................................................9

1.9. Location of main components.......................................................................................................................................10

2. TECHNICAL FEATURES OF STANDARD MACHINES (DIMENSIONS AND PERFORMANCE)......................................11

2.1. Vibrations and noise .....................................................................................................................................................13

3. SAFETY PRECAUTIONS.....................................................................................................................................................14

3.1. Personal protective equipment (PPE)...........................................................................................................................14

3.2. General safety norms....................................................................................................................................................14

3.3. Use instructions ............................................................................................................................................................15

3.3.1. General.................................................................................................................................................................15

3.3.2. Handling................................................................................................................................................................15

3.3.3. Operating procedures ...........................................................................................................................................16

3.3.4. Pressure of the machine on ground and load-bearing capacity of ground............................................................18

3.3.5. High-tension lines .................................................................................................................................................19

3.4. Hazardous situations and/or accidents.........................................................................................................................19

4. INSTALLATION AND PRELIMINARY CHECKS.................................................................................................................20

4.1. Becoming acquainted with the machine .......................................................................................................................20

4.2. Preliminary operation checks........................................................................................................................................20

5. USE INSTRUCTIONS ..........................................................................................................................................................21

5.1. Platform control panel...................................................................................................................................................21

5.1.1. ON-OFF locking key selector................................................................................................................................22

5.1.2. Drive and steering.................................................................................................................................................23

5.1.3. Platform lifting/lowering.........................................................................................................................................24

5.1.4. Electrically-controlled lowering/lifting of the mobile loading surface (OPTIONAL)................................................25

5.1.5. Loading surface manual positioning (STANDARD) ..............................................................................................26

5.1.6. Further platform control panel functions................................................................................................................27

5.1.6.1. Emergency STOP button (E) ............................................................................................................................27

5.1.6.2. Horn (J).............................................................................................................................................................27

5.1.6.3. Battery / hour-meter / display indicator (L) - circular indicator...........................................................................27

5.1.6.4. Battery / hour-meter / display indicator (L) - AIRO DIAGNOSTIC SYSTEM.....................................................28

5.2. Ground control panel ....................................................................................................................................................29

5.2.1. Emergency STOP button (power circuit) (A).........................................................................................................30

5.2.2. Emergency STOP button (control circuit) (B)........................................................................................................30

5.2.3. Platform lifting/lowering lever (C) ..........................................................................................................................30

5.2.4. Brake release switch for emergency towing (D)....................................................................................................31

5.2.5. Fuses (E) ..............................................................................................................................................................31