airpower eur

o

pe GmbH, Auf der Hohl 7,

D-53547 Datt

en

berg,

www.airpower-gmbh.com, [email protected]om 2

CONTENT

1. INFORMATION FOR THE OPERATOR .............................................................................................................. 3

1.1 CLASSIFICATION OF SAFETY INSTRUCTIONS ................................................................................................. 3

1.2 SAFETY AND WARNINGS ............................................................................................................................. 4

1.3 IMPROPER USE OR MODIFICATION OF THE DEVICE ..................................................................................... 4

1.4 INSTALLATION AND MAINTENANCE ............................................................................................................ 4

1.5 SCOPE OF DELIVERY .................................................................................................................................... 5

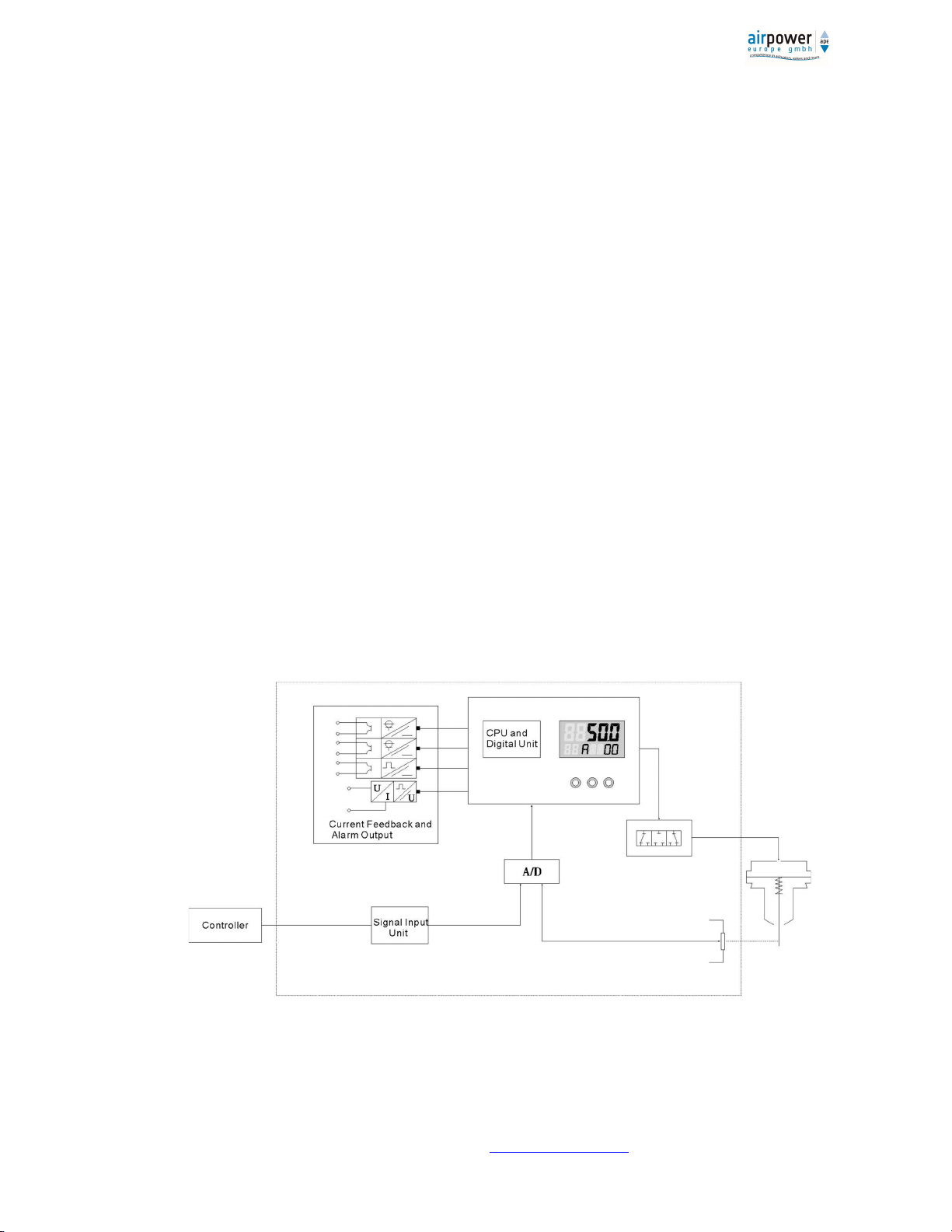

2. SUMMARY .................................................................................................................................................... 5

2.1 FUNCTIONS ................................................................................................................................................. 6

2.2 SPECIAL FEATURES ....................................................................................................................................... 6

2.3 INTEGRATED LIGHTNING PROTECTION ........................................................................................................ 6

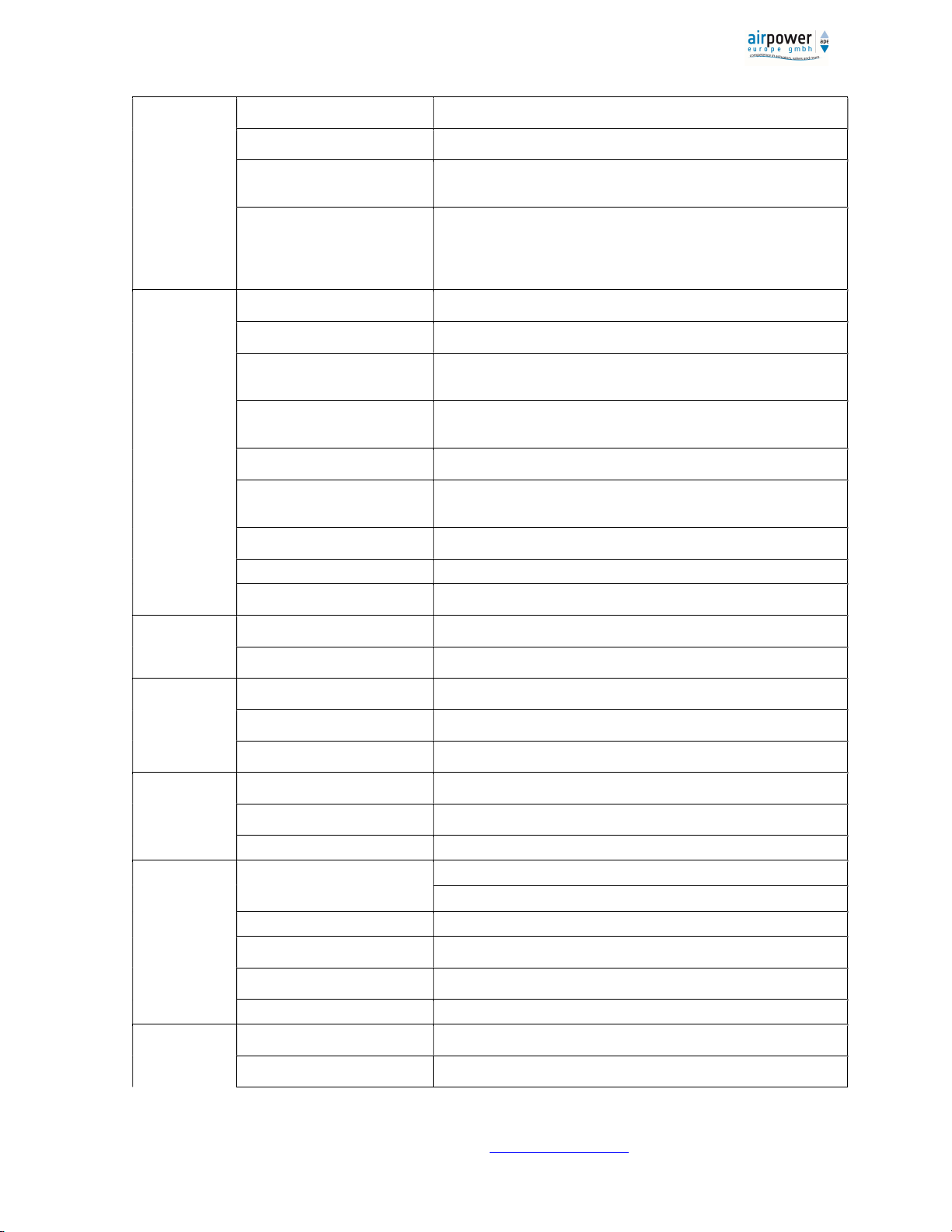

3. TECHNICAL DATA ........................................................................................................................................... 7

4 INSTALLATION .............................................................................................................................................. 8

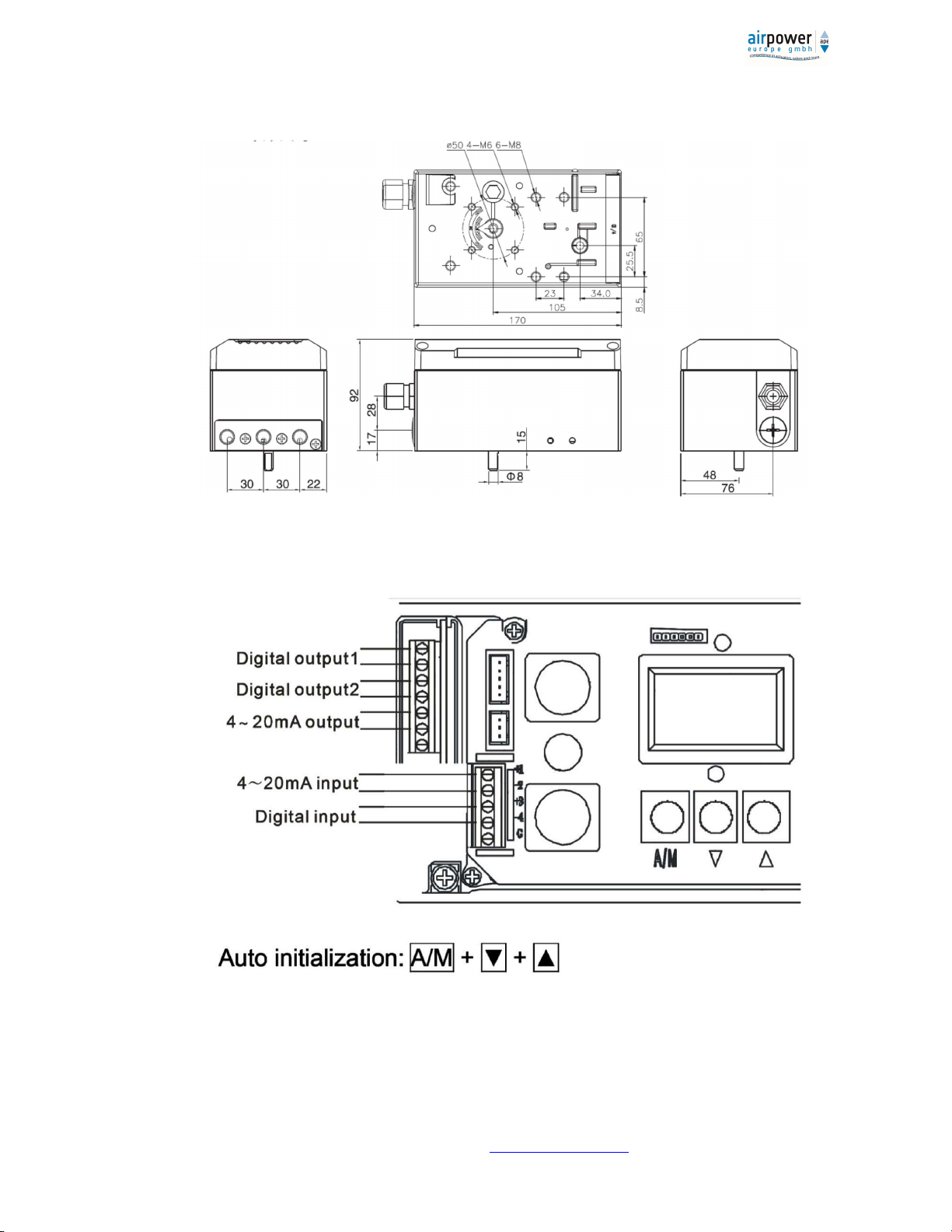

4.1 DIMENSIONS ............................................................................................................................................... 8

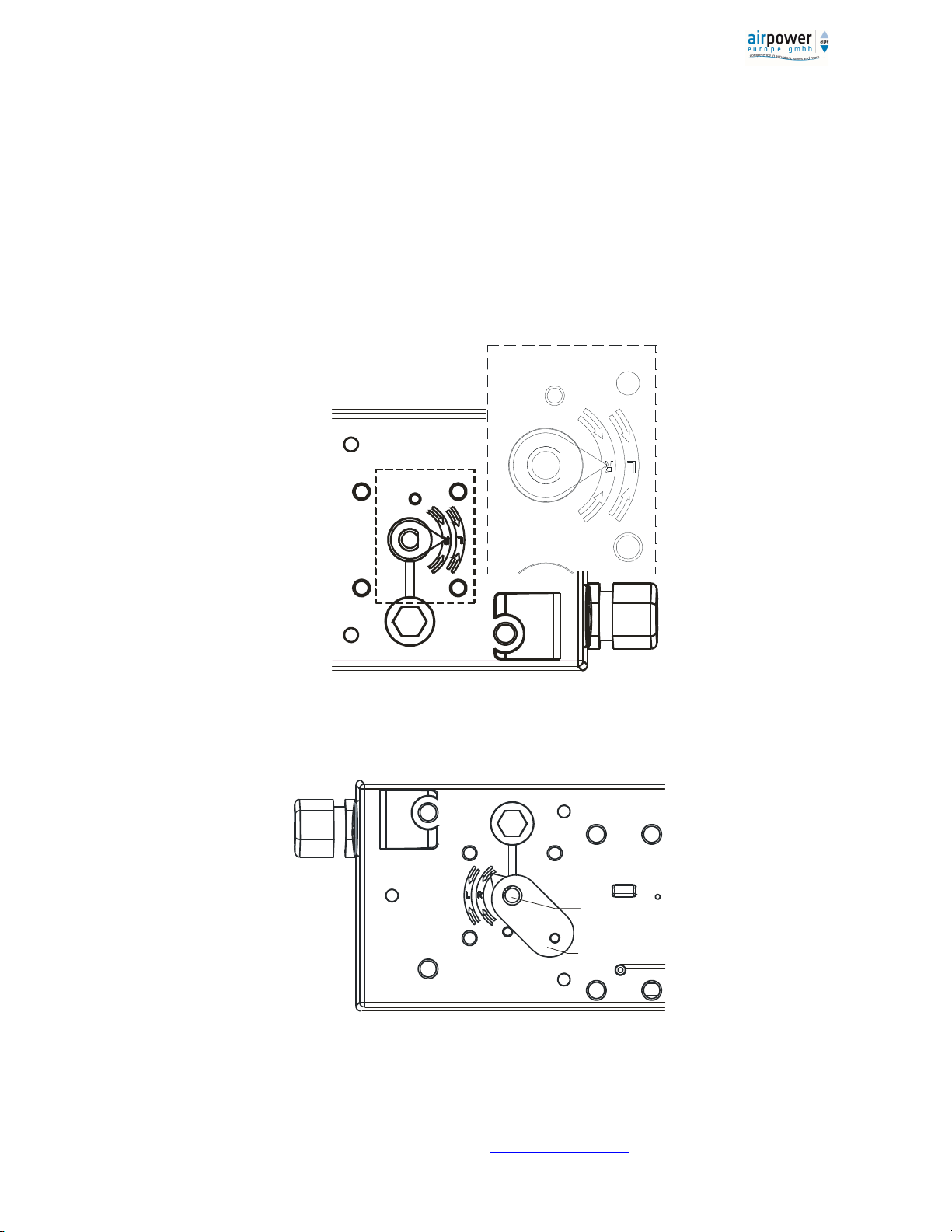

4.2 INSTALLATION ........................................................................................................................................... 9

5. OPERATION ................................................................................................................................................. 17

5.1 INTERFACE DESCRIPTION (USER INTERFACE) ........................................................................................... 17

5.1.1 DISPLAY .................................................................................................................................................. 17

5.1.2 BUTTONS................................................................................................................................................ 18

5.2 CONFIGURATION MODE ............................................................................................................................ 19

5.2.1 ENTERING TO CONFIGURATION MODE ................................................................................................... 19

5.2.2 CHOOSING A CONFIGURATION PARAMETER .......................................................................................... 19

5.2.3 CHANGING A PARAMETER ...................................................................................................................... 21

5.2.4 RESET USER PARAMETERS .................................................................................................................... 21

5.2.5 EXIT CONFIGURATION MODE ................................................................................................................. 21

5.3 INITIALIZATION .......................................................................................................................................... 21

5.3.1 EXAMINATION BEFORE INITIALIZATION .................................................................................................. 22

5.3.2 AUTOMATIC CALIBRATION ..................................................................................................................... 22

5.3.3 MANUAL CALIBRATION .......................................................................................................................... 23

5.4 DIAGNOSTIC MODE ................................................................................................................................... 24

5.4.1 SWITCHING TO DIAGNOSTIC MODE ........................................................................................................ 24

5.4.2 EXIT THE DIAGNOSTIC MODE ................................................................................................................. 24

5.4.3 DIAGNOSTIC PARAMETER....................................................................................................................... 24

5.5 ALARM ...................................................................................................................................................... 24

5.5.1 ZERO POINT OF POSITION SENSOR TOO LOW ......................................................................................... 24

5.5.2 END POINT OF THE POSITION SENSOR TOO HIGH................................................................................... 24

5.5.3 INITIALIZATION ERROR ........................................................................................................................... 25

5.5.4 MEASURING SPAN-RANGE IS INSUFFICIENT ........................................................................................... 25

5.5.5 USER CHARACTERISTICS SETTING ERROR ............................................................................................... 25