AIRTUG®Dumpster Tugs

Assembly & Operating Instructions

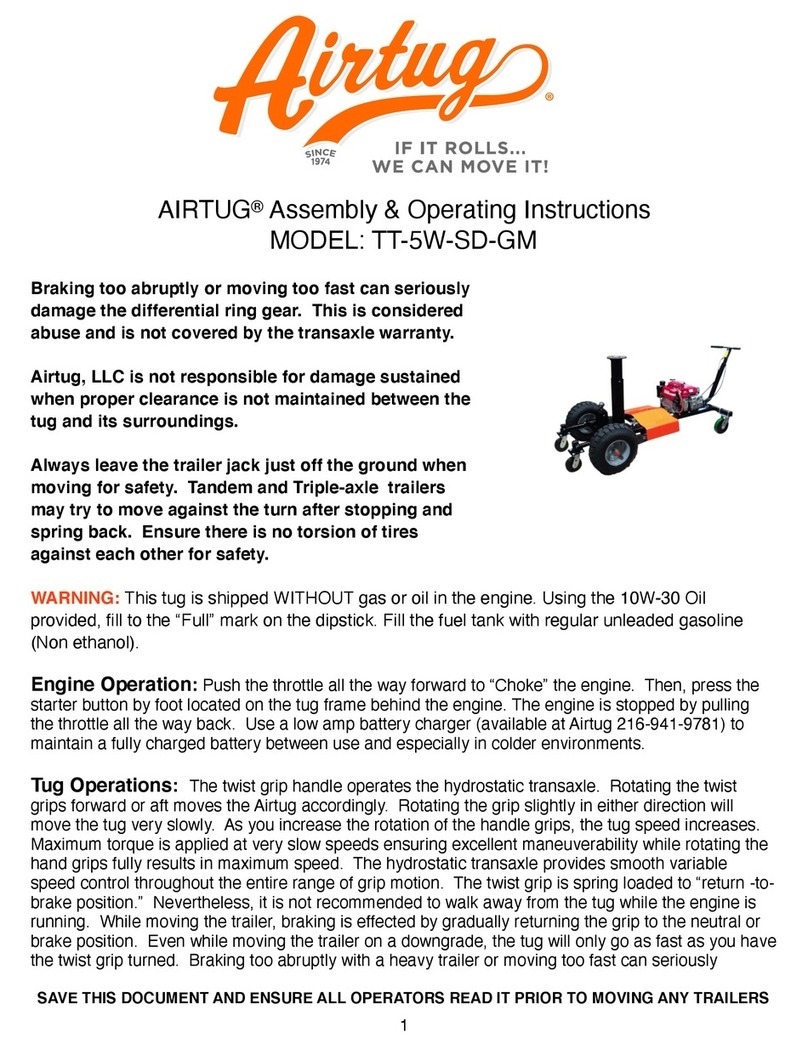

MODEL: HD Dumpster Tug GAS (5,000 Lbs)

Airtug, LLC is not responsible for damage sustained when proper

clearance is not maintained by the operator between the tug and its

surroundings.

Caution: Braking too abruptly or moving too fast can seriously

damage the differential ring gear. This is considered abuse and is

not covered by the transaxle warranty.

Note: All reference to “right” and “left” orientation is made while standing behind

the tug, looking forward from the operator position.

WARNING: This tug is shipped WITH oil in the engine. Always check oil

level prior to use. Refer to engine manual for additional information.

Recommendations: Ensure the rear wheels of the dumpster are fixed in place and DO NOT caster

or rotate. The front wheels can and should rotate or caster for ease of movement when not using the

Airtug®. At least 15% of length of dumpster needs to be beyond rear caster (ie - 100 inch long

dumpster - need at least 15 inches from center of fixed caster to rear edge of dumpster). For

dumpsters with a gross weight over 3,000 pounds, the rear fixed caster should be placed such that

20% of the dumpster is beyond the fixed caster (ie. - 100 inch long dumpster - need at least 20” from

center of fixed caster to rear edge of dumpster).

Engine Operation: Slide the throttle control on side of engine to the “choke” position. Press the

starter button by foot located on the tug frame behind the engine. Once the engine starts, adjust the

engine RPM with the control on the side of the engine. Higher RPM for heavier trailers and a lower

RPM for lighter trailers. Use a low amp battery charger (available at Airtug 216-941-9781) to maintain

a fully charged battery between use and especially in colder environments. The engine is stopped by

sliding the engine throttle on the the side in the opposite direction of the “choke” position.

Tug Operations: The twist grip handle operates the hydrostatic transaxle. Rotating the twist grips

forward or aft moves the Airtug accordingly. Rotating the grip slightly in either direction will move the

tug very slowly. As you increase the rotation of the handle grips, the tug speed increases. Maximum

torque is applied at very slow speeds ensuring excellent maneuverability while rotating the hand grips

fully results in maximum speed. The hydrostatic transaxle provides smooth variable speed control

throughout the entire range of grip motion. The twist grip is spring loaded to “return -to-brake

position.” Nevertheless, it is not recommended to walk away from the tug while the engine is running.

While moving a dumpster, braking is effected by gradually returning the grip to the neutral or brake

position. Even while moving the dumpster on a downgrade, the tug will only go as fast as you have