Cimarron MC-24BXT-KIT User manual

Page 1

Any Questions, Comments or Problems: Call your nearest Cimarron Location

and speak with one of our Friendly Technical Support Staff.

[5195837 (08/23)]

507-388-6295

800-394-7662

800-634-2026

877-974-7166

MANKATO, MN

NEWTON, KS

PASCO, WA

TEMPE, AZ

877-724-2236

800-274-1025

800-227-4098

701-280-2862

800-637-7172

BAKERSFIELD, CA

COLUMBUS, NE

DOTHAN, AL

FARGO, ND

HOPKINSVILLE, KY

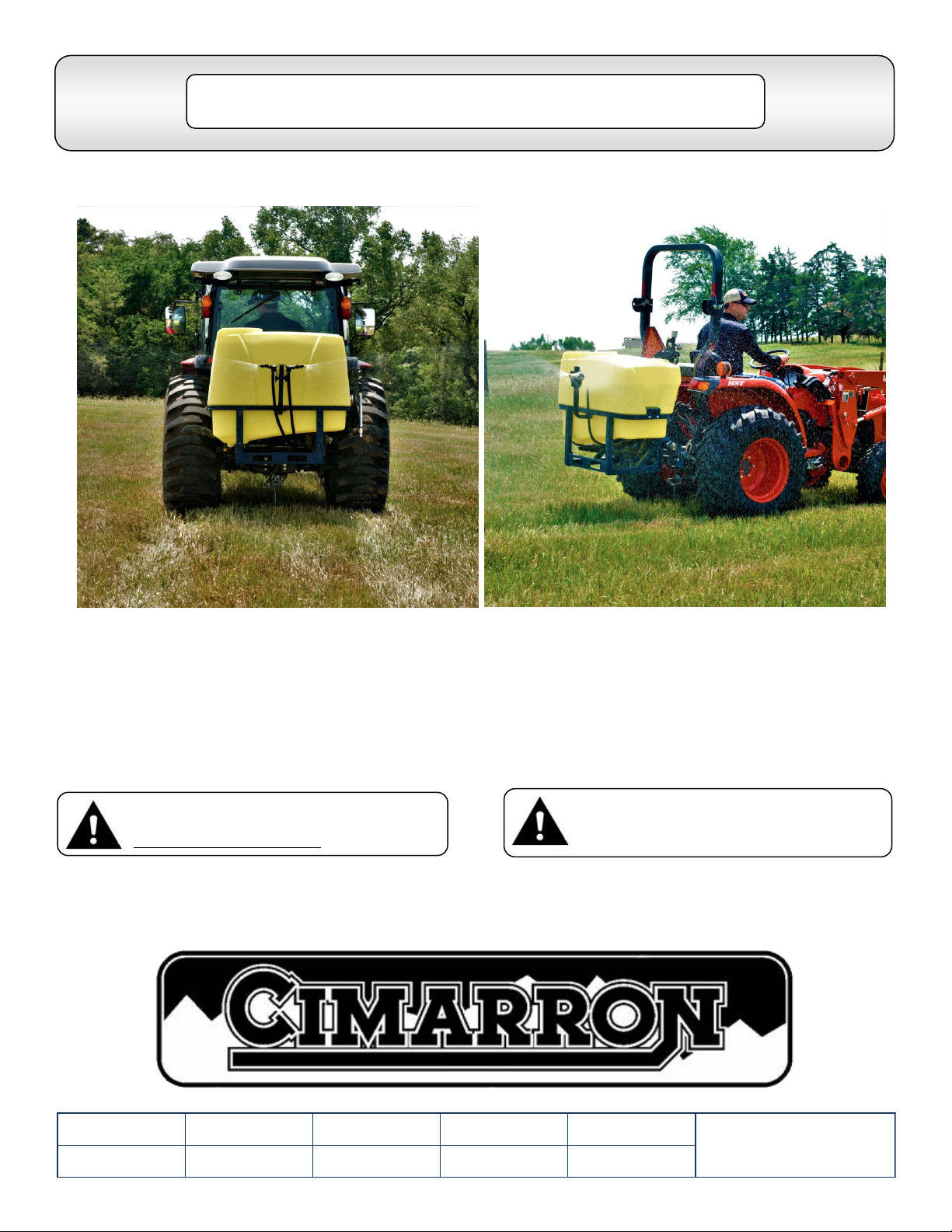

OWNER’S MANUAL

Cimarron MC-24BXT-KIT & MC1-10HAM-KIT

WARNING: Cancer and Reproducve Harm.

www.P65Warnings.ca.gov

WARNING: To reduce the risk of injury, the

user must read and understand the operator’s

manual before using this product.

MC-24BXT-KIT MC1-10HAM-KIT

Page 8

Calibrang the Sprayer

When spraying with a boom, the sprayer must be calibrated to ensure proper spray coverage and to combat over-applicaon or

under applicaon. Before calibrang the sprayer, it is important to familiarize yourself with the operang instrucons.

The calibraon process is simplied when broken down into the following three steps:

1. Determine the speed of the tractor

2. Determine the nozzle size and use the calibraon chart to nd the correct pressure seng

3. Set the pressure accordingly using the pressure regulang valve

1. Determining the Speed

It is important to determine what speed the tractor will be traveling at, while spraying. While some tractors have speedometers, it

is sll recommended that speed is calculated for all tractors for accuracy purposes. To determine the speed follow these steps:

1. Set the tractor throle to operate between 75%-100% of the tractor’s RPM range. This will allow the pump to operate at full

volume

2. Measure a 200 foot or 300 foot distance on a eld or a surface similar to where you will be spraying

3. Drive the tractor and sprayer (tank half-full is opmal) across the measured distance at a constant rate of speed. There should

be no changes in speed while you are measuring the me. This should be a comfortable speed for spraying

4. Have someone measure the amount of me (in seconds) it takes to travel the measured distance

5. Your speed can be found by entering your data into the equaon below or by consulng the speed table

Speed (MPH) = (Distance (FT) x 60)/(Time (Seconds) x 88)

_____(MPH) = _____(FT) x 60/ _____(SEC) x 88

Note: When calculang tractor speed be sure to

select a gear that allows the tractor to operate be-

tween 75%-100% of the tractor’s RPM range. This will

allow the pump to operate at full volume. Selecng a

higher gear will not allow the pump to work

eciently.

Note: All calibraon must be done with clean water only! Note: it is helpful for future references to record the exact

RPM and gear that was used to aain the desired speed

Tractor RPM Tractor Gear = Speed

___________ ___________ _________________

100 Ft. 200 Ft. 300 Ft.

1.0 68 sec. 136 205

2.0 34 68 102

3.0 23 45 68

4.0 17 34 51

5.0 14 27 41

6.0 11 23 34

7.0 9.7 19 29

8.0 8.5 17 26

9.0 7.6 15 23

10.0 6.8 14 20

Speed Chart

Time Required in seconds

to travel a distance of

Speed in M.P.H.

(Miles Per Hour)

Page 9

Calibrang the Sprayer

2. Determine the nozzle size and use the calibraon chart

Always follow the chemical manufacturers label recommendaons for applicaon rate (GPA). There are ve things you will need to

know to be able to gure your nozzle size and pressure seng. They are:

1. Applicaon rate — GPA or GAL/1000 Sq. Ft.

2. Speed — MPH

3. Width — Nozzle Spacing (in inches) for broadcast boom spraying

— Spray width (in inches) for boomless nozzles

4. Spraying Pressure — Follow chemical label recommendaons for pressure/droplet size requirements

5. Soluon weight and conversion factor (CF)

Spraying Soluons Other than Water

Since all the tabulaons are based on spraying water, which weighs 8.34 lbs. per USA gallon, conversion factors must be used when

spraying soluons which are heavier or lighter than water. To determine the proper size nozzle for the soluon to be sprayed, rst

mulply the desired GPM or GPA of soluon by the rate conversion factor. Then use the new converted GPM or GPA rate to select

the proper size nozzle and pressure.

Example: Desired applicaon rate is 20 GPA of 28% Nitrogen. Determine the

correct nozzle size as follows:

GPA (Soluon) x Conversion Factor = Converted GPA

20 GPA (28% x 1.13 = 22.6 GPA (Water), the applicator should choose a

nozzle size that will supply 22.6 GPA of water at the desired pressure.

See the appropriate Applicaon Chart for your boom spraying nozzle or

boomless nozzle. Using the tractor speed, nozzle width or spray width,

nozzle size being used and desired gallons per acre (GPA), nd the

pressure (psi) necessary to achieve the desired GPA.

Example for tradional boom sprayer: Assume you have found your tractor speed to be 6 MPH, your nozzle spacing is 20”, and

you want to spray 15 GPA and your sprayer has blue AIXR11003VP nozzles. Upon looking at the applicaon chart, you will nd that

you should set the sprayer’s pressure at about 40 psi in order to apply about 15 GPA.

Example for boomless sprayer: Assume you have found your tractor speed to be 5 MPH, your nozzle will cover 216 inches (18 Ft)

mounted 48” height above the target spray zone, and you will want to spray 15 GPA and your sprayer has yellow XT024 nozzles.

Upon looking at the applicaon chart, you will nd that you should set the sprayer’s pressure at about 50 psi in order to apply

about 15 GPA.

Useful Formulas

GPM =GPA x MPH x W GPM —Gallons Per Minute

(Per Nozzle) 5,940 GPA —Gallons Per Acre

GAL/1000 Sq. Ft. —Gallons Per 1000 Square Feet

GPM =GAL/1000 Sq. Ft. x MPH x W MPH —Miles Per Hour

(Per Nozzle) 136 W—Nozzle Spacing (in inches) for broadcast spraying

—Spray width (in inches) for single nozzle,

Band spraying or Boomless spraying

Weight of Solution

Specific

Gravity

Conversion

Factors

7.0 lbs. per gallon .84 .92

8.0 lbs. per gallon .96 .98

8.345 lbs. per gallon

(Water)

1.00 1.00

9.0 lbs. per gallon 1.08 1.04

10.0 lbs. per gallon 1.20 1.10

10.66 lbs. per gallon

(28% Nitrogen)

1.28 1.13

11.0 lbs. per gallon 1.32 1.15

12.0 lbs. per gallon 1.44 1.20

14.0 lbs. per gallon 1.68 1.30

Page 10

Calibrang the Sprayer

3. Adjusng the Sprayer Pressure

Once you have found the correct pressure (psi) seng, you must now adjust the sprayer to that pressure seng. Before you adjust

the sprayer’s pressure, it is important to follow these steps:

1. Make sure the sprayer tank is at least half full of clean water and the tank supply shuto valve to the pump is open.

2. Make sure the pressure relief valve is backed out so at least 4 threads are showing. If not, loosen the jam nut and screw the

knob out unl at least 4 threads can be seen.

3. Make sure the valves to the agitator are open, if equipped.

4. With the booms on, idle tractor and engage the tractor PTO to start the pump. Slowly increase tractor RPM, paying aenon

to the sprayer pressure gauge. (Do NOT spike the sprayer pressure gauge). If you over pressurize the spray system you can

damage the pressure gauge and sprayer plumbing. Increase the tractor’s RPM unl you reach RPM that was used to set the

tractor’s speed.

5. Adjust the pressure relief valve to reach your desired psi for your speed and GPA. This is achieved by loosening the jam nut on

the pressure relief valve and screwing the knob in to increase pressure and out to decrease pressure. Once you have reached

your desired pressure, ghten the jam nut to lock the pressure control knob. If you can not achieve enough pressure, slowly

close the agitaon valve. Tighten the valve nut to lock the agitaon valve, if equipped.

You have successfully calibrated the sprayer.

Fimco # Mfg. Part #

5143199 23120-3/4-PP

5143200 23120-1/2-PP

5168717 PK-AB23120-KIT

Description

Pressure Relief Valve (3/4" NPT)

Pressure Relief Valve (1/2" NPT)

Repair Kit, Items Marked * *

Page 11

Calibrang the Sprayer

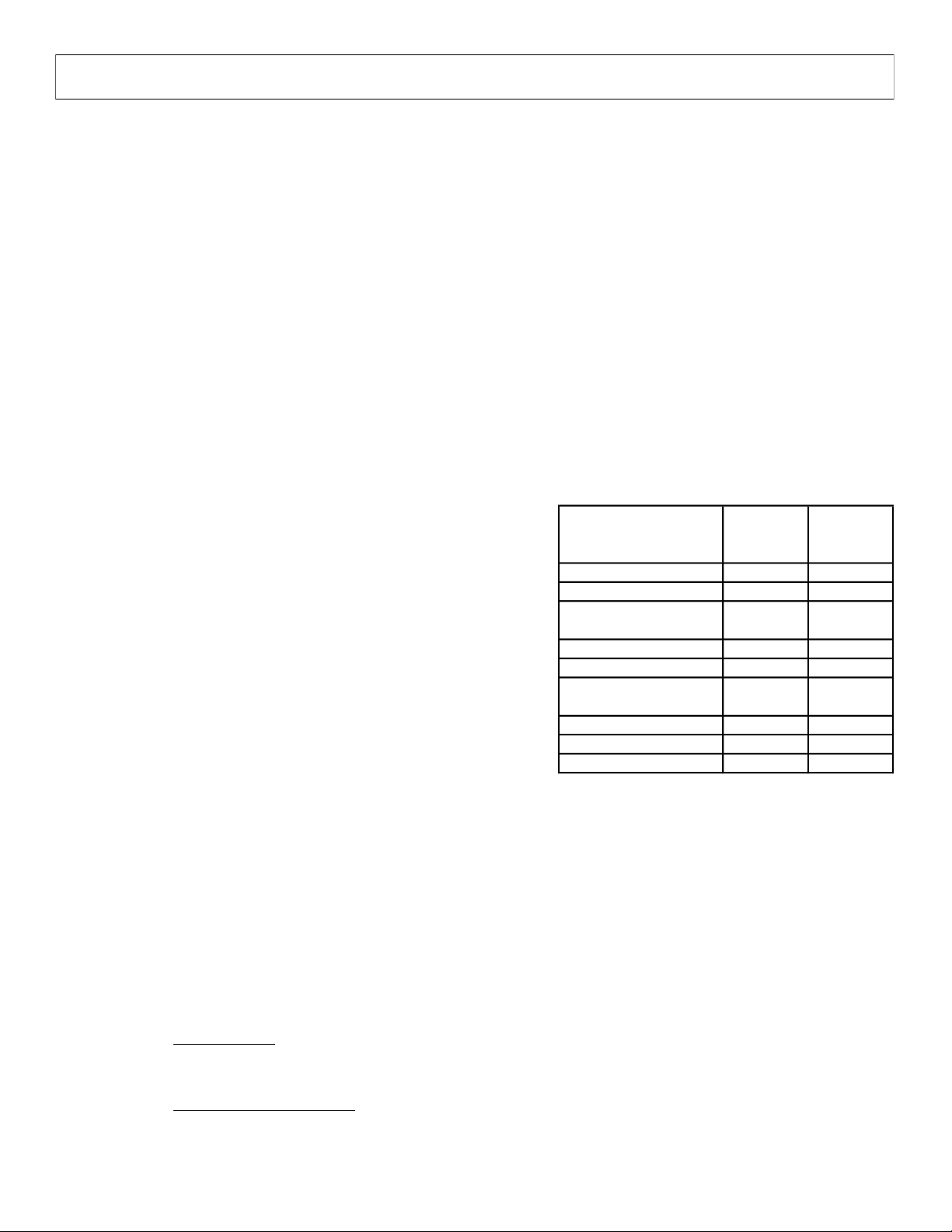

Calibraon Chart

There are many different sizes and styles of spray tips available to meet your

spraying needs. If you need further information, please contact an Cimarron

Service Center for assistance.

Please Note: Flow rates are calculated using fresh water.

Always remember to double check applicaon rates.

Boomless Nozzle Applicaon

Hypro Boom X Tender

Boomless Nozzles

NOTE: 90° nozzles have the same GPA, but 1/2 GPM and swath

NOTE: Applicaon rates are based on overall swath widths listed at 48” height. Refer to operang instrucons if using a dierent swath.

HAMILTON BOOMLESS NOZZLES

4 5 6 8 10 12 15 20 2 3 4 5

30 0.9 8.9 7.1 5.9 4.5 3.6 3.0 2.4 1.8 0.41 0.27 0.20 0.16

40 1.0 9.9 7.9 6.6 5.0 4.0 3.3 2.6 2.0 0.45 0.30 0.23 0.18

50 1.1 10.9 8.7 7.3 5.4 4.4 3.6 2.9 2.2 0.50 0.33 0.25 0.20

60 1.2 11.9 9.5 7.9 5.9 4.8 4.0 3.2 2.4 0.55 0.36 0.27 0.22

30 1.3 10.9 8.7 7.3 5.4 4.4 3.6 2.9 2.2 0.53 0.35 0.26 0.21

40 1.5 12.5 10.0 8.3 6.3 5.0 4.2 3.4 2.5 0.61 0.41 0.30 0.24

50 1.7 13.7 11.0 9.2 6.9 5.5 4.6 3.7 2.8 0.67 0.45 0.33 0.27

60 1.8 15.0 12.0 10.0 7.5 6.0 5.0 4.0 3.0 0.73 0.49 0.37 0.29

30 1.7 13.6 10.9 9.0 6.8 5.4 4.5 3.6 2.7 0.62 0.42 0.31 0.25

40 2.0 16.0 12.8 10.6 8.0 6.4 5.3 4.3 3.2 0.73 0.49 0.37 0.29

50 2.2 17.6 14.1 11.7 8.8 7.0 5.9 4.7 3.5 0.81 0.54 0.40 0.32

60 2.4 19..2 15.3 12.8 9.6 7.7 6.4 5.1 3.8 0.88 0.59 0.44 0.35

30 2.1 16.2 13.0 10.8 8.1 6.5 5.4 4.3 3.2 0.75 0.50 0.37 0.30

40 2.4 18.6 14.9 12.4 9.3 7.4 6.2 5.0 3.7 0.85 0.57 0.43 0.34

50 2.7 20.9 16.7 13.9 10.4 8.4 7.0 5.6 4.2 0.96 0.64 0.48 0.38

60 2.9 22.4 17.9 15.0 11.2 9.0 7.5 6.0 4.5 1.03 0.69 0.51 0.41

30 3.7 31.6 25.3 21.1 15.8 12.6 10.5 8.4 6.3 1.45 0.97 0.72 0.58

40 4.3 36.7 29.4 24.5 18.3 14.7 12.2 9.8 7.3 1.68 1.12 0.75 0.67

50 4.8 41.0 32.8 27.3 20.5 16.4 13.7 10.9 8.2 1.88 1.25 0.94 0.75

60 5.3 45.2 36.2 30.2 22.6 18.1 15.1 12.1 9.0 2.08 1.38 1.04 0.83

30 6.9 68.3 54.6 45.5 34.2 27.3 22.8 18.2 13.7 3.14 2.09 1.57 1.25

40 8.0 79.2. 63.4 52.8 39.6 31.7 26.4 21.1 15.8 3.64 2.42 1.82 1.45

50 8.9 88.1 70.5 58.7 44.1 35.2 29.4 23.5 17.6 4.04 2.70 2.02 1.62

60 9.8 97.0 77.6 64.7 48.5 38.8 32.3 25.9 19.4 4.45 2.97 2.23 1.78

30 14.5 128.0 103.0 85.4 64.1 51.3 42.7 34.2 25.6 5.88 3.92 2.94 2.35

40 16.7 148.0 118.0 98.4 73.8 59.0 49.2 39.4 29.5 6.78 4.52 3.39 2.71

50 18.7 165.0 132.0 110.0 82.6 66.1 55.1 44.1 33.1 7.59 5.06 3.79 3.03

60 20.5 181.0 145.0 121.0 90.6 72.5 60.4 48.3 36.2 8.32 5.54 4.16 3.33

30 18.6 144.0 115.0 95.9 71.9 57.5 48.0 38.4 28.8 6.60 4.40 3.30 2.64

40 21.5 166.0 133.0 111.0 83.1 66.5 55.4 44.3 33.3 7.63 5.09 3.82 3.05

50 24.0 186.0 149.0 124.0 92.8 74.3 61.9 49.5 37.1 8.52 5.68 4.26 3.41

60 26.3 203.0 163.0 136.0 102.0 81.4 67.8 54.2 40.7 9.34 6.22 4.67 3.73

16

14

15

16

14

13

15

215

(3/4")

Nozzle

Size

(MNPT)

Pressure

(PSI)

Flow

Rate

(GPM)

43

(3/8")

80

(1/2")

167

(3/4")

15

(1/4")

20

(1/4")

24

(1/4")

Gallons per Acre

GAL/1000 Sq. Ft.

MPH

MPH

10

(1/4")

Swath (Ft)

at 40 PSI

48" High

13

3 MPH 4 MPH 5 MPH 8 MPH 10 MPH

30 1.7 44' 6.4 4.8 3.8 2.4 1.9

40 2.0 46' 7.2 5.4 4.3 2.7 2.2

50 2.2 48' 7.6 5.7 4.5 2.9 2.3

60 2.4 50' 7.9 5.9 4.8 3.0 2.4

30 3.7 50' 12.2 9.2 7.3 4.6 3.7

40 4.2 50' 13.9 10.4 8.3 5.2 4.2

50 4.6 52' 14.6 10.9 8.8 5.5 4.4

60 5.0 52' 15.8 11.9 9.5 5.9 4.8

30 5.1 54' 15.6 11.6 9.3 5.8 4.7

40 5.9 54' 18.0 13.5 10.8 6.8 5.4

50 6.7 56' 19.7 14.8 11.8 7.4 5.9

60 7.1 58' 20.2 15.1 12.1 7.6 6.1

#20

Operating Data for 1800 Nozzles

Gallons per Acre

Orifice

No.

PSI

GPM

180°

Swath

180°

#5

#10

Page 12

Calibrang the Sprayer

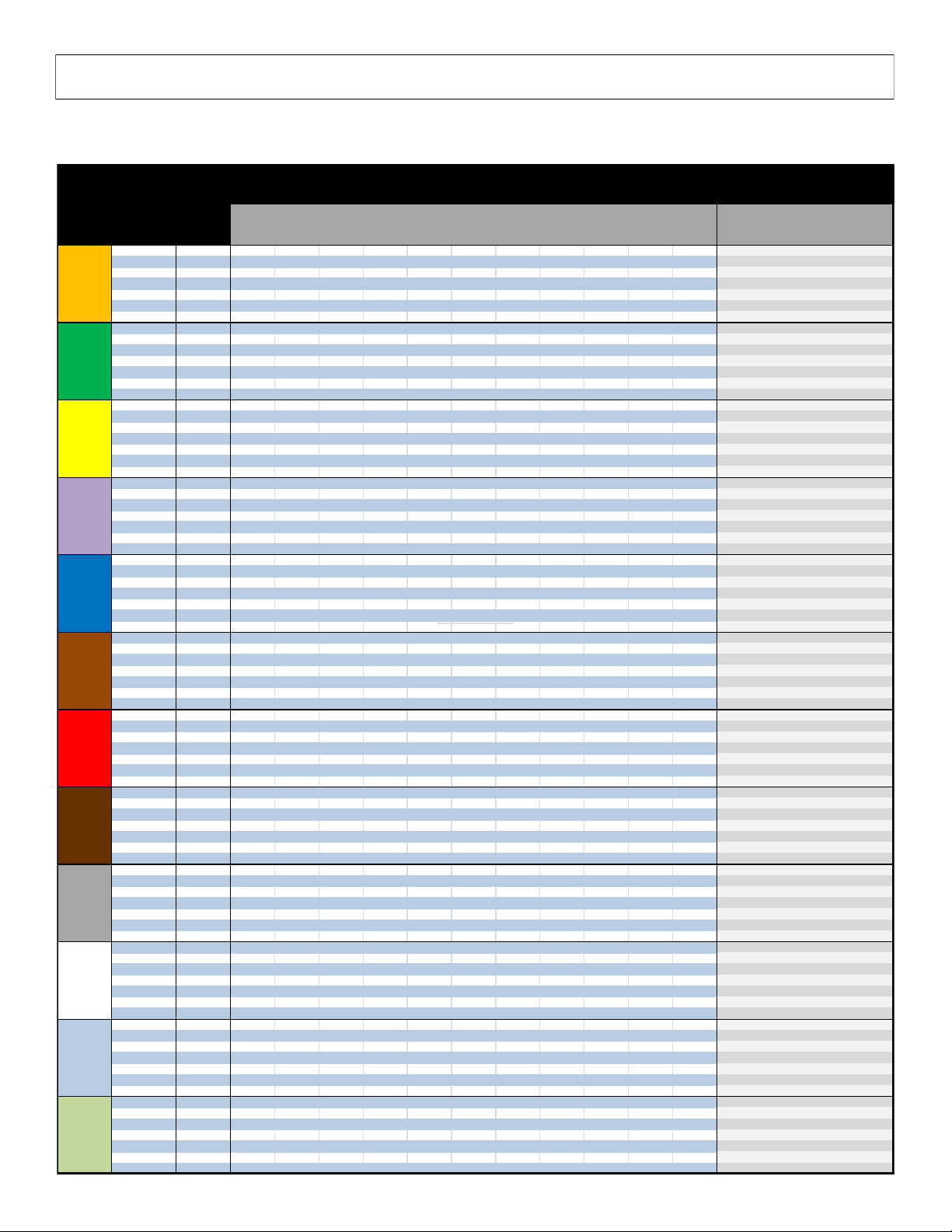

BROADCAST & TURF APPLICATION CHART—20” SPACING

4 5 6 7 8 10 12 14 16 18 20 2 3 4 5

15 0.06 4.5 3.6 3.0 2.5 2.2 1.8 1.5 1.3 1.1 1.0 0.9 0.20 0.14 1.00 0.08

30 0.09 6.7 5.3 4.5 3.8 3.3 2.7 2.2 1.9 1.7 1.5 1.3 0.31 0.20 0.15 0.12

40 0.10 7.4 5.9 5.0 4.2 3.7 3.0 2.5 2.1 1.9 1.7 1.5 0.34 0.23 0.17 0.14

60 0.12 8.9 7.1 5.9 5.1 4.5 3.6 3.0 2.5 2.2 2.0 1.8 0.41 0.27 0.20 0.16

80 0.14 10.4 8.3 6.9 5.9 5.2 4.2 3.5 3.0 2.6 2.3 2.1 0.48 0.32 0.24 0.19

100 0.16 11.9 9.5 7.9 6.8 5.9 4.8 4.0 3.4 3.0 2.6 2.4 0.55 0.36 0.27 0.22

115 0.17 12.6 10.1 8.4 7.2 6.3 5.0 4.2 3.6 3.2 2.8 2.5 0.58 0.39 0.29 0.23

15 0.09 6.7 5.3 4.5 3.8 3.3 2.7 2.2 1.9 1.7 1.5 1.3 0.31 0.20 0.15 0.12

30 0.13 9.7 7.7 6.4 5.5 4.8 3.9 3.2 2.8 2.4 2.1 1.9 0.44 0.30 0.22 0.18

40 0.15 11.1 8.9 7.4 6.4 5.6 4.5 3.7 3.2 2.8 2.5 2.2 0.51 0.34 0.26 0.20

60 0.18 13.4 10.7 8.9 7.6 6.7 5.3 4.5 3.8 3.3 3.0 2.7 0.61 0.41 0.31 0.25

80 0.21 15.6 12.5 10.4 8.9 7.8 6.2 5.2 4.5 3.9 3.5 3.1 0.72 0.48 0.36 0.29

100 0.24 17.8 14.3 11.9 10.2 8.9 7.1 5.9 5.1 4.5 4.0 3.6 0.82 0.55 0.41 0.33

115 0.25 18.6 14.9 12.4 10.6 9.3 7.4 6.2 5.3 4.6 4.1 3.7 0.85 0.57 0.43 0.34

15 0.12 8.9 7.1 5.9 5.1 4.5 3.6 3.0 2.5 2.2 2.0 1.8 0.41 0.27 0.20 0.16

30 0.17 12.6 10.1 8.4 7.2 6.3 5.0 4.2 3.6 3.2 2.8 2.5 0.58 0.39 0.29 0.23

40 0.20 14.9 11.9 9.9 8.5 7.4 5.9 5.0 4.2 3.7 3.3 3.0 0.68 0.45 0.34 0.27

60 0.24 17.8 14.3 11.9 10.2 8.9 7.1 5.9 5.1 4.5 4.0 3.6 0.82 0.55 0.41 0.33

80 0.28 20.8 16.6 13.9 11.9 10.4 8.3 6.9 5.9 5.2 4.6 4.2 0.95 0.64 0.48 0.38

100 0.32 23.8 19.0 15.8 13.6 11.9 9.5 7.9 6.8 5.9 5.3 4.8 1.09 0.73 0.55 0.44

115 0.34 25.2 20.2 16.8 14.4 12.6 10.1 8.4 7.2 6.3 5.6 5.0 1.16 0.77 0.58 0.46

15 0.15 11.1 8.9 7.4 6.4 5.6 4.5 3.7 3.2 2.8 2.5 2.2 0.51 0.34 0.26 0.20

30 0.22 16.3 13.1 10.9 9.3 8.2 6.5 5.4 4.7 4.1 3.6 3.3 0.75 0.50 0.38 0.30

40 0.25 18.6 14.9 12.4 10.6 9.3 7.4 6.2 5.3 4.6 4.1 3.7 0.85 0.57 0.43 0.34

60 0.31 23.0 18.4 15.3 13.2 11.5 9.2 7.7 6.6 5.8 5.1 4.6 1.06 0.70 0.53 0.42

80 0.35 26.0 20.8 17.3 14.9 13.0 10.4 8.7 7.4 6.5 5.8 5.2 1.19 0.80 0.60 0.48

100 0.40 29.7 23.8 19.8 17.0 14.9 11.9 9.9 8.5 7.4 6.6 5.9 1.36 0.91 0.68 0.55

115 0.42 31.2 24.9 20.8 17.8 15.6 12.5 10.4 8.9 7.8 6.9 6.2 1.43 0.95 0.72 0.57

15 0.18 13.4 10.7 8.9 7.6 6.7 5.3 4.5 3.8 3.3 3.0 2.7 0.61 0.41 0.31 0.25

30 0.26 19.3 15.4 12.9 11.0 9.7 7.7 6.4 5.5 4.8 4.3 3.9 0.89 0.59 0.44 0.35

40 0.30 22.3 17.8 14.9 12.7 11.1 8.9 7.4 6.4 5.6 5.0 4.5 1.02 0.68 0.51 0.41

60 0.37 27.5 22.0 18.3 15.7 13.7 11.0 9.2 7.8 6.9 6.1 5.5 1.26 0.84 0.63 0.50

80 0.42 31.2 24.9 20.8 17.8 15.6 12.5 10.4 8.9 7.8 6.9 6.2 1.43 0.95 0.72 0.57

100 0.47 34.9 27.9 23.3 19.9 17.4 14.0 11.6 10.0 8.7 7.8 7.0 1.60 1.07 0.80 0.64

115 0.51 37.9 30.3 25.2 21.6 18.9 15.1 12.6 10.8 9.5 8.4 7.6 1.74 1.16 0.87 0.70

15 0.21 15.6 12.5 10.4 8.9 7.8 6.2 5.2 4.5 3.9 3.5 3.1 0.72 0.48 0.36 0.29

30 0.30 22.3 17.8 14.9 12.7 11.1 8.9 7.4 6.4 5.6 5.0 4.5 1.02 0.68 0.51 0.41

40 0.35 26.0 20.8 17.3 14.9 13.0 10.4 8.7 7.4 6.5 5.8 5.2 1.19 0.80 0.60 0.48

60 0.43 31.9 25.5 21.3 18.2 16.0 12.8 10.6 9.1 8.0 7.1 6.4 1.47 0.98 0.73 0.59

80 0.49 36.4 29.1 24.3 20.8 18.2 14.6 12.1 10.4 9.1 8.1 7.3 1.67 1.11 0.84 0.67

100 0.55 40.8 32.7 27.2 23.3 20.4 16.3 13.6 11.7 10.2 9.1 8.2 1.88 1.25 0.94 0.75

115 0.59 43.8 35.0 29.2 25.0 21.9 17.5 14.6 12.5 11.0 9.7 8.8 2.01 1.34 1.01 0.80

15 0.24 17.8 14.3 11.9 10.2 8.9 7.1 5.9 5.1 4.5 4.0 3.6 0.82 0.55 0.41 0.33

30 0.35 26.0 20.8 17.3 14.9 13.0 10.4 8.7 7.4 6.5 5.8 5.2 1.19 0.80 0.60 0.48

40 0.40 29.7 23.8 19.8 17.0 14.9 11.9 9.9 8.5 7.4 6.6 5.9 1.36 0.91 0.68 0.55

60 0.49 36.4 29.1 24.3 20.8 18.2 14.6 12.1 10.4 9.1 8.1 7.3 1.67 1.11 0.84 0.67

80 0.57 42.3 33.9 28.2 24.2 21.2 16.9 14.1 12.1 10.6 9.4 8.5 1.94 1.30 0.97 0.78

100 0.63 46.8 37.4 31.2 26.7 23.4 18.7 15.6 13.4 11.7 10.4 9.4 2.15 1.43 1.07 0.86

115 0.68 50.5 40.4 33.9 28.9 25.2 20.2 16.8 14.4 12.6 11.2 10.1 2.32 1.55 1.16 0.93

15 0.31 23.0 18.4 15.3 13.2 11.5 9.2 7.7 6.6 5.8 5.1 4.6 1.06 0.70 0.53 0.42

30 0.43 31.9 25.5 21.3 18.2 16.0 12.8 10.6 9.1 8.0 7.1 6.4 1.47 0.98 0.73 0.59

40 0.50 37.1 29.7 24.8 21.2 18.6 14.9 12.4 10.6 9.3 8.3 7.4 1.71 1.14 0.85 0.68

60 0.61 45.3 36.2 30.2 25.9 22.6 18.1 15.1 12.9 11.3 10.1 9.1 2.08 1.39 1.04 0.83

80 0.71 52.7 42.2 35.1 30.1 26.4 21.1 17.6 15.1 13.2 11.7 10.5 2.42 1.61 1.21 0.97

100 0.79 58.7 46.9 39.1 33.5 29.3 23.5 19.6 16.8 14.7 13.0 11.7 2.69 1.80 1.35 1.08

115 0.85 63.1 50.5 42.1 36.1 31.6 25.2 21.0 18.0 15.8 14.0 12.6 2.90 1.93 1.45 1.16

15 0.37 27.5 22.0 18.3 15.7 13.7 11.0 9.2 7.8 6.9 6.1 5.5 1.26 0.84 0.63 0.50

30 0.52 38.6 30.9 25.7 22.1 19.3 15.4 12.9 11.0 9.7 8.6 7.7 1.77 1.18 0.89 0.71

40 0.60 44.6 35.6 29.7 25.5 22.3 17.8 14.9 12.7 11.1 9.9 8.9 2.05 1.36 1.02 0.82

60 0.73 54.2 43.4 36.1 31.0 27.1 21.7 18.1 15.5 13.6 12.0 10.8 2.49 1.66 1.24 1.00

80 0.85 63.1 50.5 42.1 36.1 31.6 25.2 21.0 18.0 15.8 14.0 12.6 2.90 1.93 1.45 1.16

100 0.95 70.5 56.4 47.0 40.3 35.3 28.2 23.5 20.2 17.6 15.7 14.1 3.24 2.16 1.62 1.30

115 1.02 75.7 60.6 50.5 43.3 37.9 30.3 25.2 21.6 18.9 16.8 15.1 3.48 2.32 1.74 1.39

15 0.49 36.4 29.1 24.3 20.8 18.2 14.6 12.1 10.4 9.1 8.1 7.3 1.67 1.11 0.84 0.67

30 0.69 51.2 41.0 34.2 29.3 25.6 20.5 17.1 14.6 12.8 11.4 10.2 2.35 1.57 1.18 0.94

40 0.80 59.4 47.5 39.6 33.9 29.7 23.8 19.8 17.0 14.9 13.2 11.9 2.73 1.82 1.36 1.09

60 0.98 72.8 58.2 48.5 41.6 36.4 29.1 24.3 20.8 18.2 16.2 14.6 3.34 2.23 1.67 1.34

80 1.13 83.9 67.1 55.9 47.9 42.0 33.6 28.0 24.0 21.0 18.6 16.8 3.85 2.57 1.93 1.54

100 1.26 93.6 74.8 62.4 53.5 46.8 37.4 31.2 26.7 23.4 20.8 18.7 4.30 2.86 2.15 1.72

115 1.36 101.0 80.8 67.3 57.7 50.5 40.4 33.7 28.9 25.2 22.4 20.2 4.64 3.09 2.32 1.86

15 0.61 45.3 36.2 30.2 25.9 22.6 18.1 15.1 12.9 11.3 10.1 9.1 2.08 1.39 1.04 0.83

30 0.87 64.6 51.7 43.1 36.9 32.3 25.8 21.5 18.5 16.1 14.4 12.9 2.97 1.98 1.48 1.19

40 1.00 74.3 59.4 49.5 42.4 37.1 29.7 24.8 21.2 18.6 16.5 14.9 3.41 2.27 1.71 1.36

60 1.22 90.6 72.5 60.4 51.8 45.3 36.2 30.2 25.9 22.6 20.1 18.1 4.16 2.77 2.08 1.66

80 1.41 104.7 83.8 69.8 59.8 52.3 41.9 34.9 29.9 26.2 23.3 20.9 4.81 3.21 2.40 1.92

100 1.58 117.3 93.9 78.2 67.0 58.7 46.9 39.1 33.5 29.3 26.1 23.5 5.39 3.59 2.69 2.16

115 1.70 126.2 101.0 84.2 72.1 63.1 0.5 42.1 36.1 31.6 28.1 25.2 5.80 3.86 2.90 2.32

15 0.92 68.3 54.6 45.5 39.0 34.2 27.3 22.8 19.5 17.1 15.2 13.7 3.14 2.09 1.57 1.25

30 1.30 96.5 77.2 64.4 55.2 48.3 38.6 32.2 27.6 24.1 21.5 19.3 4.43 2.96 2.22 1.77

40 1.50 111.4 89.1 74.3 63.6 55.7 44.6 37.1 31.8 27.8 24.8 22.3 5.12 3.41 2.56 2.05

60 1.84 136.6 109.3 91.1 78.1 68.3 54.6 45.5 39.0 34.2 30.4 27.3 6.27 4.18 3.14 2.51

80 2.12 157.4 125.9 104.9 89.9 78.7 63.0 52.5 45.0 39.4 35.0 31.5 7.23 4.82 3.61 2.89

100 2.37 176.0 140.8 117.3 100.6 88.0 70.4 58.7 50.3 44.0 39.1 35.2 8.08 5.39 4.04 3.23

115 2.54 188.6 150.9 125.7 107.8 94.3 75.4 62.9 53.9 47.1 41.9 37.7 8.66 5.77 4.33 3.46

Nozzle

Size

Pressure

(PSI)

Flow

Rate

(GPM)

Gallons per Acre

20-inch Nozzle Spacing

GAL/1000 Sq. Ft.

20-inch Nozzle Spacing

MPH

MPH

015

01

015

02

025

03

035

04

05

06

08

010

Page 13

Calibrang the Sprayer

AIXR11002VP Nozzles

Based on the minimum overlap required to obtain

uniform distribuon with 110° ps and 20” spacing.

Suggested Minimum Spray Height: 16”-18” above

what is being sprayed (to plant, not ground).

Opmum Spray Height: 20”

Pressure

(psi)

Capacity

(GPM)

1

MPH

2

MPH

3

MPH

4

MPH

5

MPH

6

MPH

8

MPH

15 .18 53.6 26.8 17.8 13.4 10.7 8.9 6.7

20 .21 62.4 31.2 20.8 15.6 12.5 10.4 7.8

30 .26 77.2 38.6 25.8 19.3 15.4 12.9 9.7

40 .30 88.0 44.0 29.8 22.0 17.8 14.9 11.1

15 .18 .61 .41 .31 .24

20 .21 .71 .48 .36 .29

30 .26 .88 .59 .44 .35

40 .30 1.0 .68 .51 .41

Gallons Per

Acre

Based on Water

Gallons Per

1000 Sq. Ft.

Based on Water

AIXR11003VP Spray Tip Rate Chart (20" Spacing)

Based on the minimum overlap required to obtain

uniform distribuon with 110° ps and 20” spacing.

Suggested Minimum Spray Height: 16”-18” above

what is being sprayed (to plant, not ground).

Opmum Spray Height: 20”

•110° wide, tapered at spray angle with air inducon technology for beer dri management

•Made of 2-piece UHMWPE polymer construcon which provides excellent chemical resistance, including acids, as well as

exceponal wear life

•Compact size to prevent p damage

•Excellent for systemic products and dri management

AIXR11003VP Nozzles

Pressure

(psi)

Capacity

(GPM)

1

MPH

2

MPH

3

MPH

4

MPH

5

MPH

6

MPH

8

MPH

15 .12 35.6 17.8 11.8 8.9 7.1 5.9 4.5

20 .14 41.6 20.8 13.8 10.4 8.3 6.9 5.2

30 .17 50.4 25.2 16.8 12.6 10.1 8.4 6.3

40 .20 59.6 29.8 19.8 14.9 11.9 9.9 7.4

15 .12 .41 .27 .20 .16

20 .14 .48 .32 .24 .19

30 .17 .58 .39 .29 .23

40 .20 .68 .45 .34 .27

Gallons Per

Acre

Based on Water

Gallons Per

1000 Sq. Ft.

Based on Water

AIXR11002VP Spray Tip Rate Chart (20" Spacing)

Pressure

(psi)

Capacity

(GPM)

2

MPH

3

MPH

4

MPH

5

MPH

6

MPH

8

MPH

10

MPH

15 .15 11.1 8.9 7.4 5.6 4.5

20 .18 13.4 10.7 8.9 6.7 5.3

30 .22 16.3 13.1 10.9 8.2 6.5

40 .25 18.6 14.9 12.4 9.3 7.4

15 .15 0.51 0.34 0.26 0.20

20 .18 0.61 0.41 0.31 0.24

30 .22 0.75 0.50 0.37 0.30

40 .25 0.85 0.57 0.43 0.34

AIXR110025VP Spray Tip Rate Chart (20" Spacing)

Gallons Per

Acre

Based on Water

Gallons Per

1000 Sq. Ft.

Based on Water

Based on the minimum overlap required to obtain

uniform distribuon with 110° ps and 20” spacing.

Suggested Minimum Spray Height: 16”-18” above

what is being sprayed (to plant, not ground).

Opmum Spray Height: 20”

AIXR110025VP Nozzles

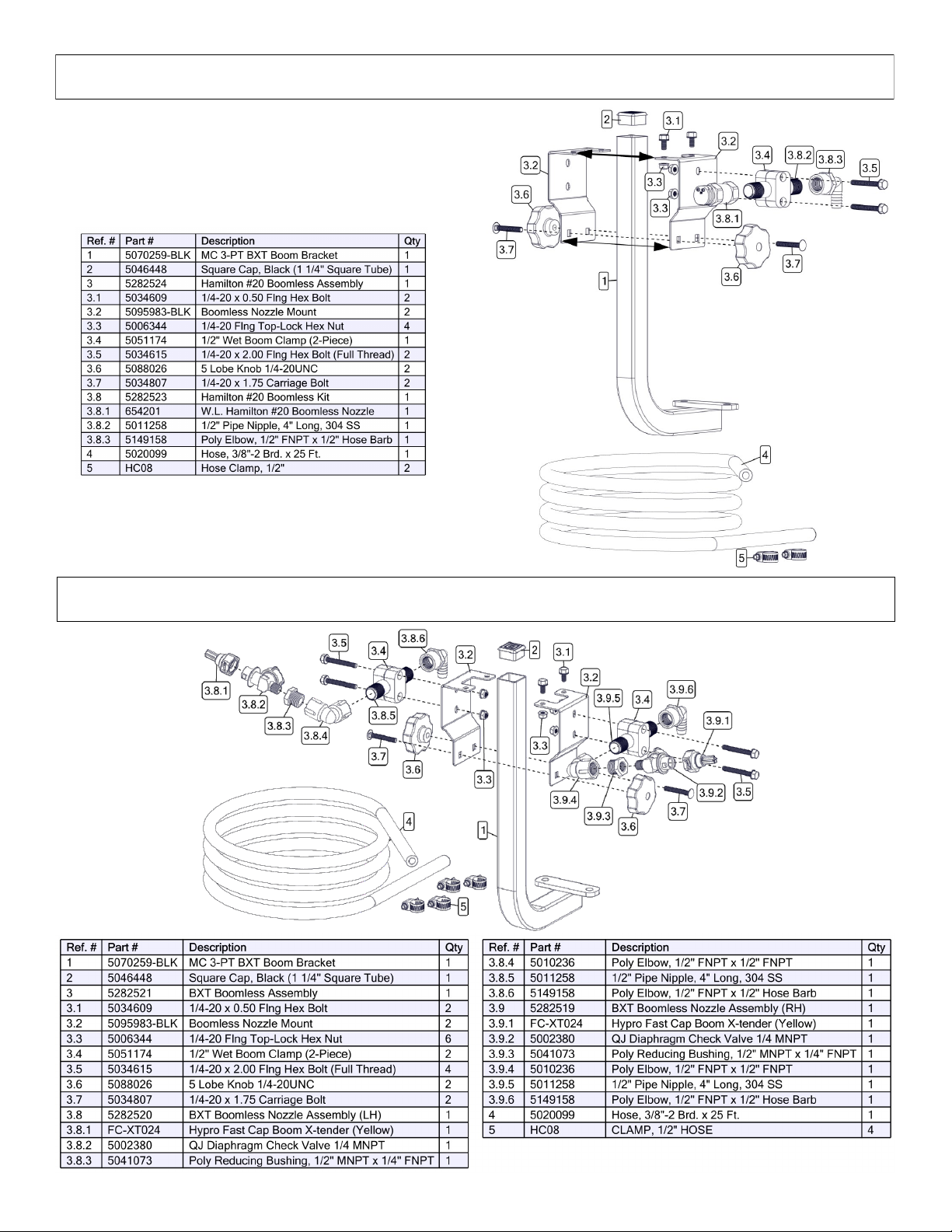

Page 32

Hamilton Boomless Assembly Component Breakdown & Parts List

BXT Boomless Nozzle Component Breakdown & Parts List

Hamilton #20 Boomless Kit MC1-20HAM-KIT (5282525)

BXT Boomless Kit

MC-24BXT-KIT (5282522)

Page 41

Warranty Info

LIMITED WARRANTY FOR NEW Cimarron EQUIPMENT

WHO MAY USE THIS LIMITED WARRANTY. This limited warranty (the “Limited Warranty”) is provided by Fimco, Inc. (“Cimarron Equipment“) to

the original purchaser (“you”) of the Equipment (as defined below) from Cimarron Equipment or one of Cimarron Equipment’s authorized dealers.

This Limited Warranty does not apply to any subsequent owner or other transferee of the Equipment. THIS LIMITED WARRANTY GIVES YOU SPE-

CIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

WHAT THIS LIMITED WARRANTY COVERS AND FOR HOW LONG. Cimarron Equipment warrants that any new Equipment will be free from defects

in material and workmanship for a period of one (1) year (homeowner), 90 days (commercial user), after delivery of the Equipment to you (the

“Warranty Period”). The Warranty Period is not extended if Cimarron Equipment repairs or replaces the Equipment.

WHAT IS NOT COVERED BY THIS LIMITED WARRANTY. This Limited Warranty does not apply to: (1) used Equipment; (2) any Equipment that has

been altered, changed, repaired or treated since its delivery to you, other than by Cimarron Equipment or its authorized dealers; (3) damage

or depreciation due to normal wear and tear; (4) defects or damage due to failure to follow Cimarron Equipment’s operator’s manual,

specifications or other written instructions, or improper storage, operation, maintenance, application or installation of parts; (5) defects or

damage due to mis-use, accident or neglect, “acts of God” or other events beyond Cimarron Equipment’s reasonable control; (6) accessories,

attachments, tools or parts that were not manufactured by Cimarron Equipment, whether or not sold or operated with the Equipment; or (7)

rubber parts, such as tires, hoses and grommets.

HOW TO OBTAIN WARRANTY SERVICE. To obtain warranty service under this Limited Warranty, you must (1) provide written notice to

Cimarron Equipment of the defect during the Warranty Period and within thirty (30) days after the defect becomes apparent or the repair

becomes neces-sary, at the following address: Cimarron Equipment, 1000 Fimco Lane, North Sioux City, SD 57049; and (2) make the Equipment

available to

Cimarron Equipment or an authorized dealer within a reasonable period of time. For more information about this Limited Warranty,

please call: 800-274-1025

WHAT REMEDIES ARE AVAILABLE UNDER THIS LIMITED WARRANTY. If the conditions set forth above are fulfilled and the Equipment or any part

thereof is found to be defective, Cimarron Equipment shall, at its own cost, and at its option, either repair or replace the defective Equipment or

part. Cimarron Equipment will pay for shipping and handling fees to return the repaired or replacement Equipment or part to you.

LIMITATION OF IMPLIED WARRANTIES AND OTHER REMEDIES. THE REMEDIES DESCRIBED ABOVE ARE YOUR SOLE AND EXCLUSIVE REMEDIES,

AND Cimarron EQUIPMENT’S SOLE LIABILITY, FOR ANY BREACH OF THIS LIMITED WARRANTY. TO THE EXTENT APPLICABLE, ANY IMPLIED WAR-

RANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

SHALL BE LIMITED IN DURATION TO THE WARRANTY PERIOD, AND THE REMEDIES AVAILABLE FOR BREACH THEREOF SHALL BE LIMITED TO THE

REMEDIES AVAILABLE UNDER THIS EXPRESS LIMITED WARRANTY. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WAR-

RANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL Cimarron EQUIPMENT’S LIABILITY UNDER THIS LIMITED

WARRANTY EXCEED THE ACTUAL AMOUNT PAID BY YOU FOR THE DEFECTIVE EQUIPMENT, NOR SHALL Cimarron EQUIPMENT BE LIABLE, UNDER

ANY CIRCUMSTANCES, FOR ANY CONSEQUENTIAL, INCIDENTAL, SPECIAL OR PUNITIVE DAMAGES OR LOSSES, WHETHER DIRECT OR INDIRECT.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

This manual suits for next models

1

Table of contents

Popular Farm Equipment manuals by other brands

GreenMech

GreenMech EcoTMP Operator's manual

MacDon

MacDon A30-S Assembly instructions

LEMKEN

LEMKEN Rubin 12 KUA operating instructions

Toro

Toro 41614 installation instructions

Patriot equipment

Patriot equipment Corn Reel Installation & operation manual

EASY COOPS

EASY COOPS Chicken Coop Plan 8x15 Assembly instructions

Buhler

Buhler Farm King Grain Vac Conveyair 6640 Operator and parts manual

breviglieri

breviglieri Hypermaster XL Operating and maintenance manual

Amazone

Amazone Cayron 200 operating manual

DEUTZ-FAHR

DEUTZ-FAHR SwatMaster 7131 Assembly instructions

Mitchell Engineering

Mitchell Engineering CAT 44SHP manual

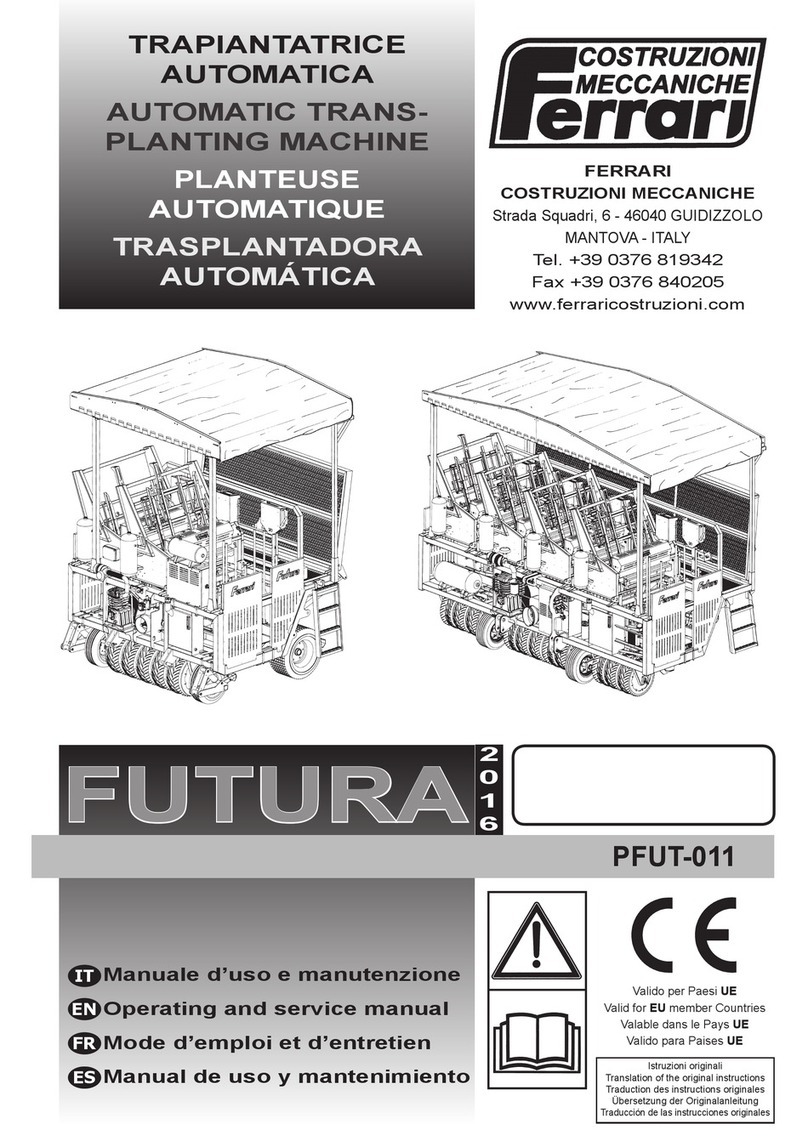

Ferrari

Ferrari FUTURA 2016 Operating and service manual