When you travel with the truck loaded tilt the mast back and keep the load low.

This will help stabilize loads with an uneven weight distribution.

When you load at high elevations, tilt the load back far enough to seat it against

the front vertical faces of the forks or the load back rest (if fitted).

When you unload at high elevations, make sure you only use enough tilt to

place the load onto the rack or stack.

Retrieving a Load

The following steps outline the proper procedure to be followed when retrieving

a load.

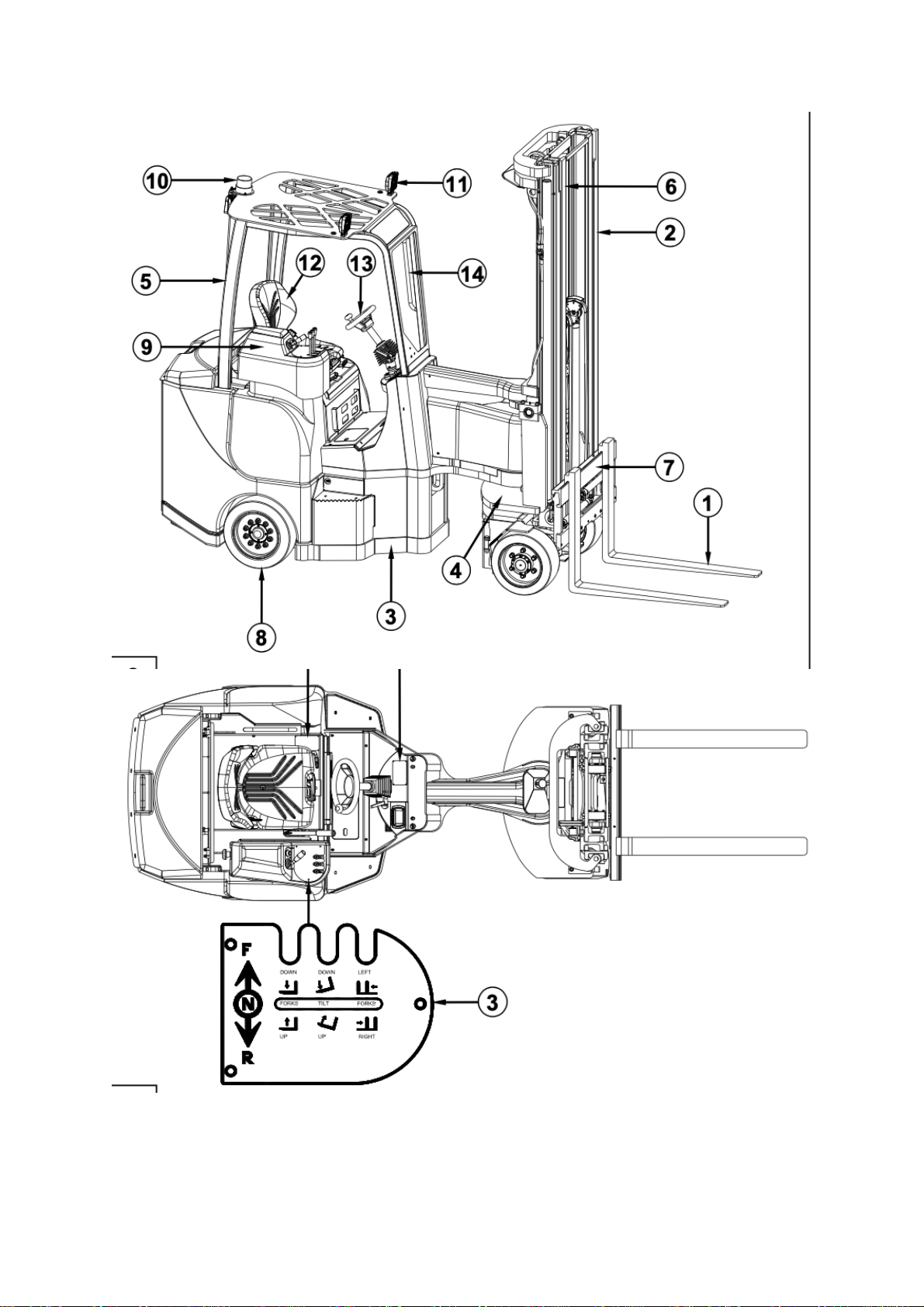

The black arrows indicate the direction to turn the steering wheel and the

grey arrows indicate the truck drive and mast carrier/fork directions.

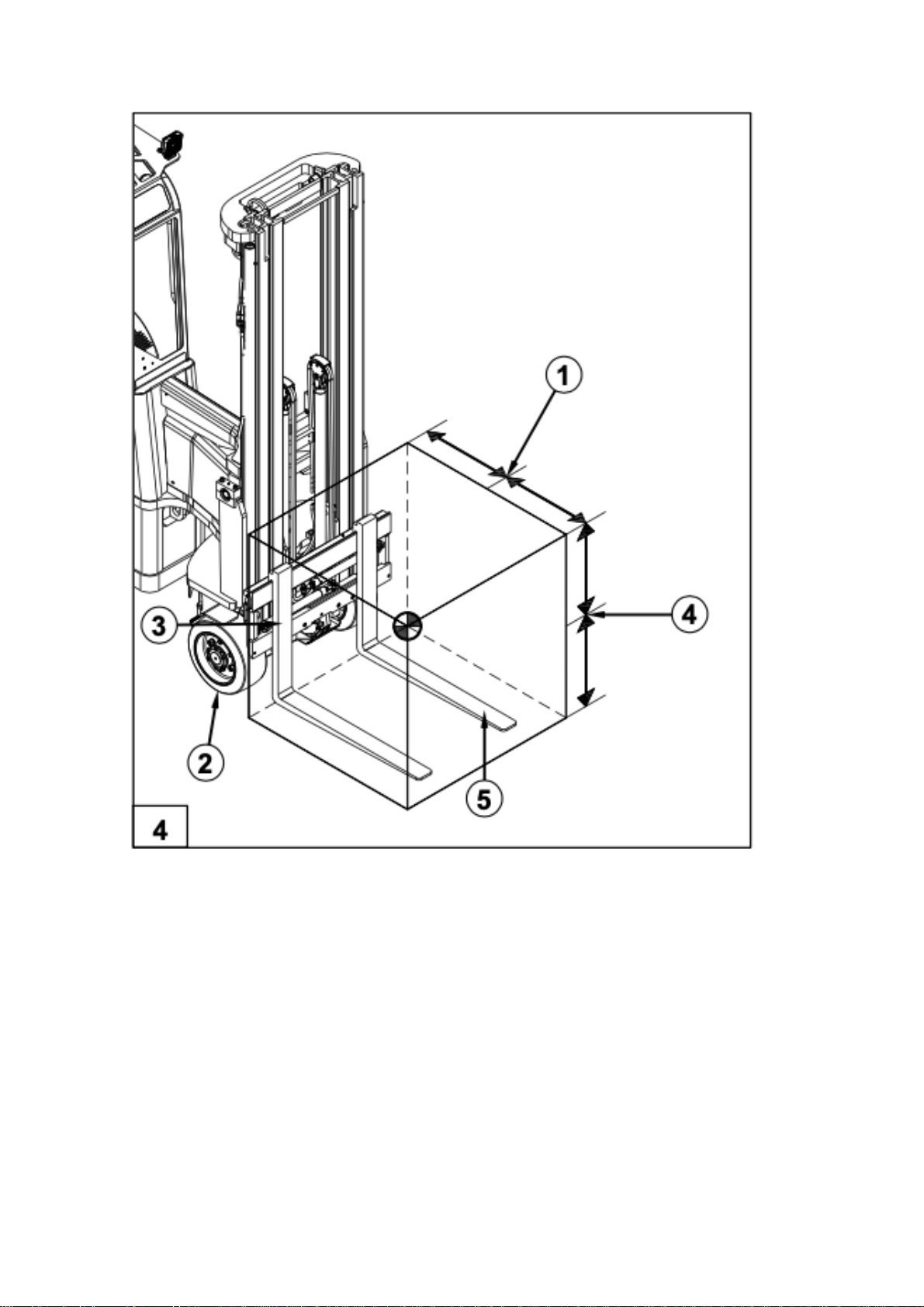

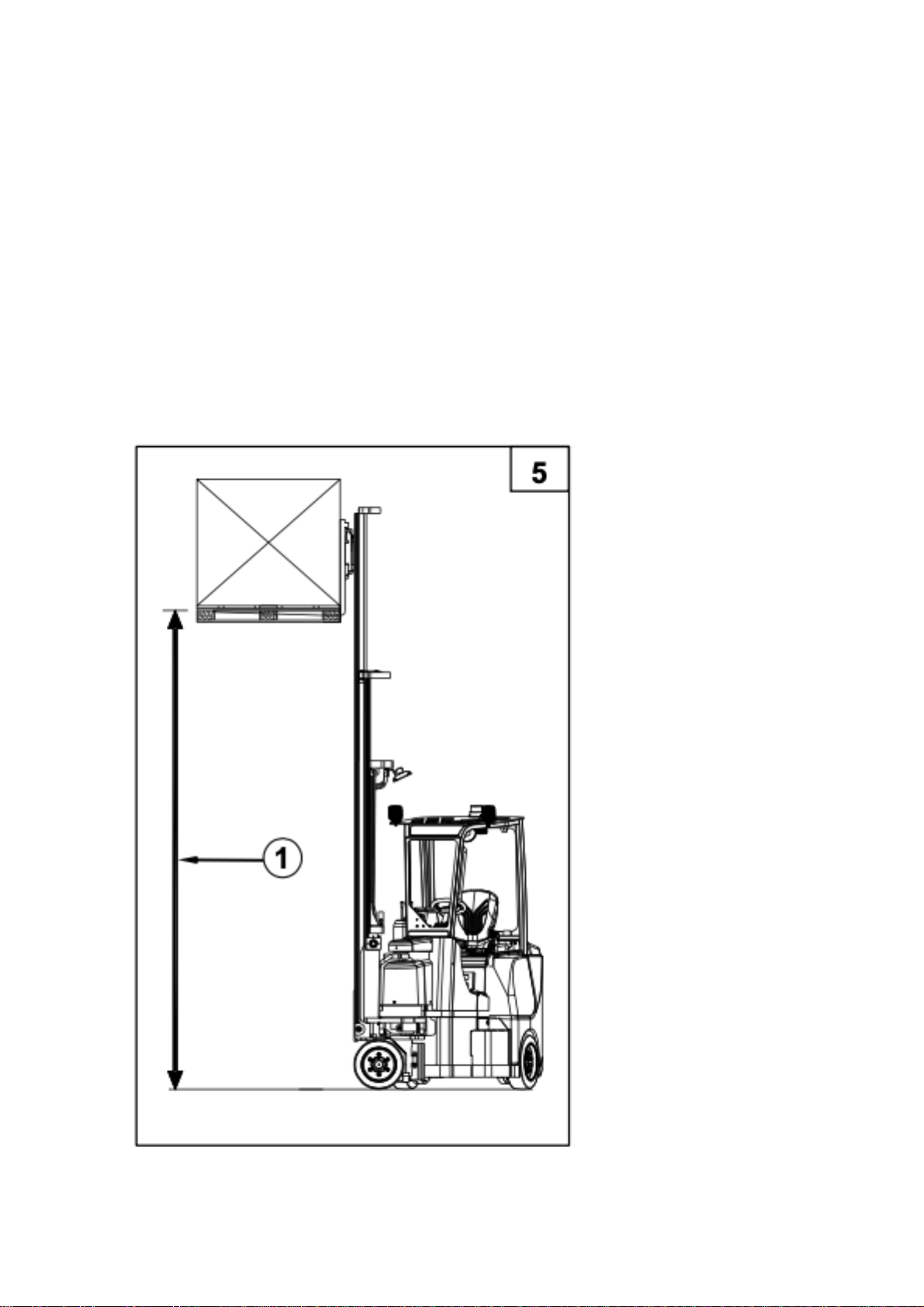

1. Drive straight down the middle of the aisle (item 1) [14] and slow down

when approaching the load (item 2) [14].

2. For narrow aisles bear to the side of the aisle that is opposite to the load

(item 3) [14]. Maintain a distance of approximately 150mm (6 inches)

between the side of the truck and the side of the aisle. For wider aisles

stay in the centre of the aisle

3. Centre the forks using the side shift.

Warning

If the forks or load jam or catch during a stacking operation, do not

attempt to free them by reaching through the mast. Failure to follow

this guideline can cause serious injury or death.

4. Drive forward until the centres of the front wheels are aligned with the

centre of the pallet/load to be lifted (item 4) [14], stop the truck and put

the direction lever into neutral.

5. Lift the forks to the required height and use the tilt to level the forks.

6. Turn the steering wheel/forks towards the load to be lifted (anticlockwise

for LHS). Stop turning when the fork nearest to the load (item 1) [15] is

approximately 100mm (4 inches) from the face of the rack/stack.

7. Set the direction lever to reverse. Slowly reverse the truck and

simultaneously turn the steering wheel/forks towards the load

(anticlockwise for LHS) until the forks are aligned central to the sides of

the load/