NOTE ON BEFORE STARTING REPAIR

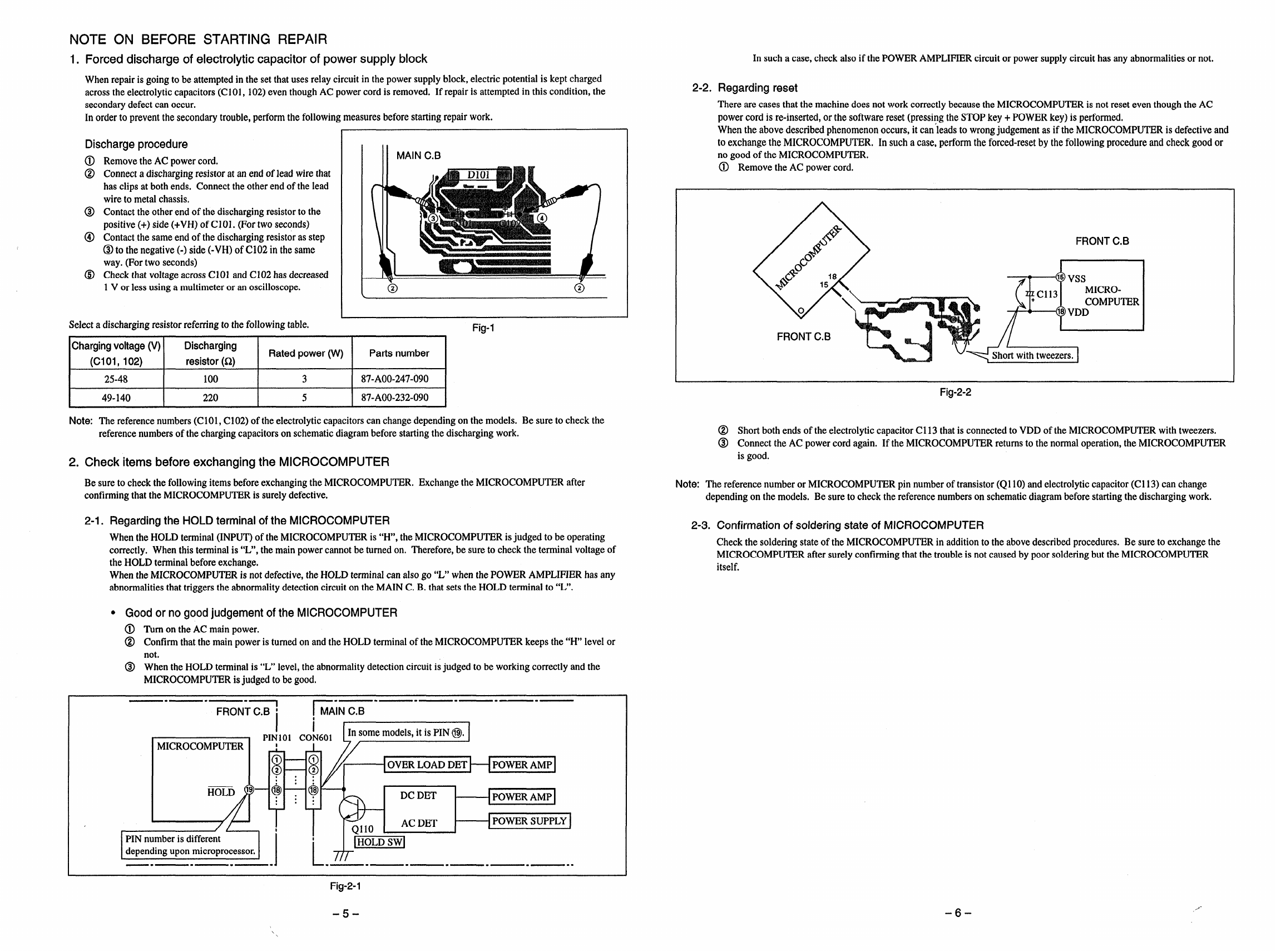

1. Forced discharge of electrolytic capacitor of power supply block

When repair is going to be attempted in the set that uses relay circuit in the power supply block, electric potential is kept charged

across the electrolytic capacitors (C101, 102) even though AC power cord is removed. If repair is attempted in this condition, the

secondary defect can occur.

In order to prevent the secondary trouble, perform the following measures before starting repair work.

Discharge procedure I II

--

Remove the AC Dowercord, I I II MAIN C.B

Connect adisch;ging resistor at an end of lead wire that

has clips at both ends. Connect the other end of the lead

wire to metal chassis,

Contact the other end of the discharging resistor to the

positive (+) side (+VH) of C101. (For two seconds)

Contact the same end of the discharging resistor as step

@to the negative (-) side (-VH) of C102 in the same

way. (For two seconds)

Check that voltage across C1OI and C102 has decreased

1Vor less using amultimeter or an oscilloscope. 66

I

Select adischarging resistor referring to the following table. Fia-1

ICharging voltage (V) Discharging Rated power (W) Parts number

(Clol, 102) resistor (Q) I

I25-48 I100 13 I87-AOO-247-090 I

I49-140 I220 15 I87-AOO-232-090 I

Note: The reference numbers (C101, C102) of the electrolytic capacitors can change depending on the models. Be sure to check the

reference numbers of the charging capacitors on schematic diagram before starting the discharging work.

2. Check items before exchanging the MICROCOMPUTER

Be sure to check the following items before exchanging the MICROCOMPUTER. Exchange the MICROCOMPUTER after

confirming that the MICROCOMPUTER is surely defective.

2-1. Regarding the HOLD terminal of the MICROCOMPUTER

When the HOLD terminal (INPUT) of the MICROCOMPUTER is “H”, the MICROCOMPUTER is judged to be operating

correctly. When this terminal is “L”, the main power cannot be turned on, Therefore, be sure to check the terminal voltage of

the HOLD terminal before exchange.

When the MICROCOMPUTER is not defective, the HOLD terminal can also go “L” when the POWER AMPLIFIER has any

abnormalities that triggers the abnormality detection circuit on the MAIN C. B. that sets the HOLD terminal to “L”.

●Good or no good judgement of the MICROCOMPUTER

@Turnon the AC main power,

@Confirm that the main power is turned on and the HOLD terminal of the MICROCOMPUTER keeps the “H” level or

not.

~When the HOLD terminal is “L” level, the abnormality detection circuit is judged to be working correctly and the

MICROCOMPUTER is judged to be good.

I—.— .—. ——.— .—. —.—. —.—

I

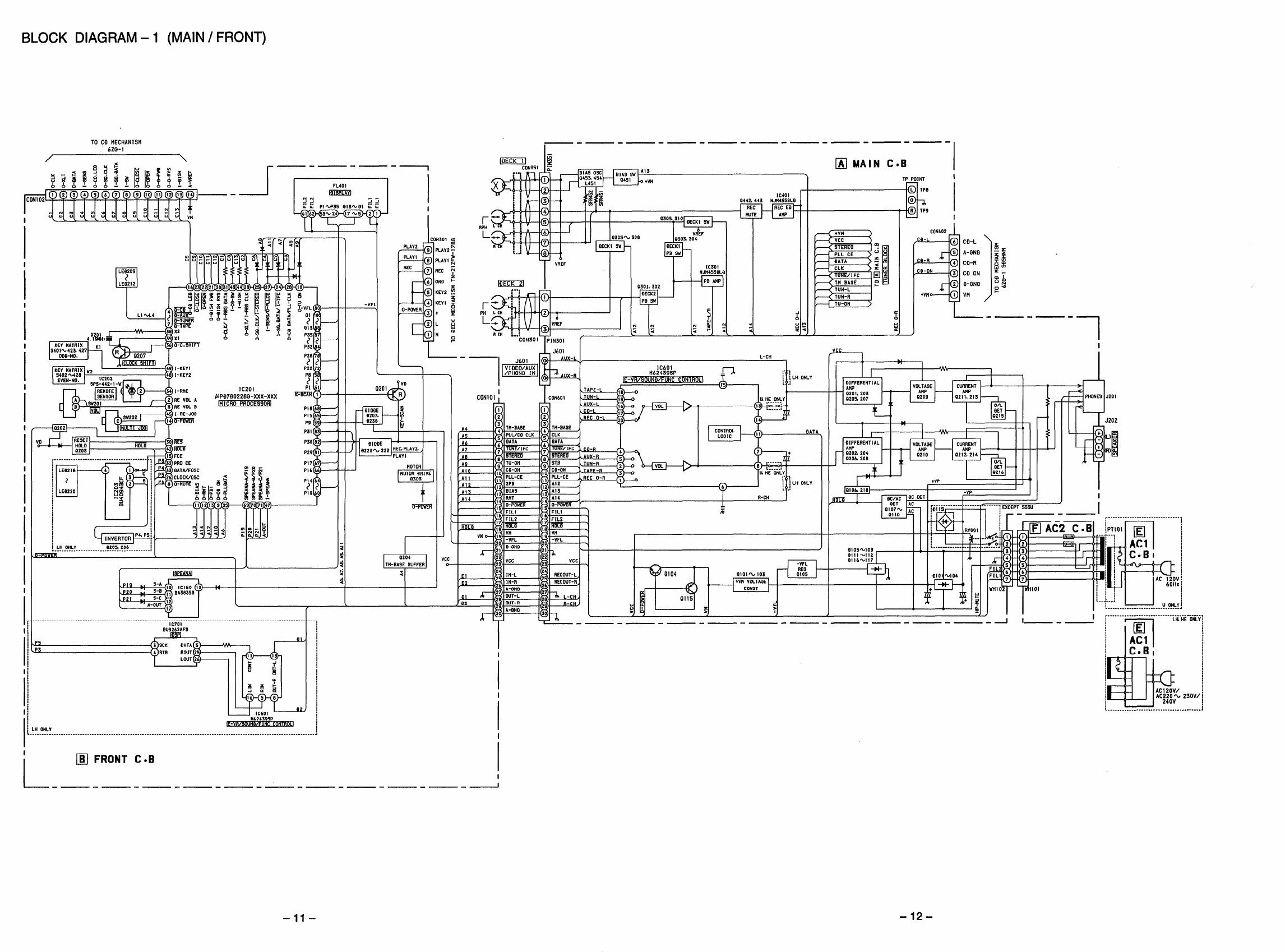

FRONT C.B :IMAIN C.B

e

111I

l.;)!~

I

PIN101 CON601

MICROCOMPUTER Il?Rlwf+ OVER LOAD DET POWER AMP

A-J (’%

=D 19— b-6

. . . DC DET

.●.POWER AMP

..

I‘%10 I‘CDETIIPOWER SUPPLY I

PIN number is different

depending upon microprocessor.

—.— .—. —.]L771-

.—. —.— .— .— .—-.

In such acase, check also if the POWER AMPLIFIER circuit or power supply circuit has any abnormalities or not.

2-2. Regarding reset

There are cases that the machine does not work correctly because the MICROCOMPUTER is not reset even though the AC

power cord is re-inserted, or the software reset (pressing the STOP key +POWER key) is performed.

When the above described phenomenon occurs, it can’leads to wrong judgement as if the MICROCOMPUTER is defective and

to exchange the MICROCOMPUTER. In such acase, perform the forced-reset by the following procedure and check good or

no good of the MICROCOMPUTER.

@Remove the AC power cord.

Fig-2-2

@Short both ends of the electrolytic capacitor Cl 13 that is connected to VDD of the MICROCOMPUTER with tweezers.

@Connmt the AC power’ cord a@n. If theMICROCOMPUTER returns to the normal operation, the MICROCOMPUTER

is good.

Note: The reference number or MICROCOMPUTER pin number of transistor (Ql 10) and electrolytic capacitor (Cl 13) can change

depending on the models. Be sure to check the reference numbers on schematic diagram before starting the discharging work.

2-3. Confirmation of soldering state of MICROCOMPUTER

Check the soldering state of the MICROCOMPUTER in addition to the above described procedures. Be sure to exchange the

MICROCOMPUTER after surely confirming that the trouble is not caused by poor soldering but the MICROCOMPUTER

itself.

Fig-2-1

-5- -6-