6

e main search mode of the device is dynamic, i.e. object detection

occurs only with constant movement of the sensor.

To determine the exact location of the detected object, the device has a

static mode of operation.

e device has two types of indication of object detection:

- sound programmable multi-mode

- visual (hodograph, VDI index, rating (level) of the PC signal)

e device implements two independent search channels: RT and ST.

e RT channel (real time, RT) is a detection channel and

operates in real time, i.e. sound indication is issued synchronously with

the movement of the sensor over the object. e sound indication in this

channel is a single-tone signal, the volume and frequency of which can

change as the object approaches the sensor. e duration of the sound

from the object can be judged on its approximate size.

When the signal from the object in the RT channel exceeds the level of

the set threshold value, the ST channel begins to work.

e ST channel (short tone, ST) is an object type identication channel.

If the threshold level of the signal from the object is exceeded, it is iden-

tied in the ST channel, then a short sound signal of the corresponding

tonality is issued, and the hodograph is displayed on the display screen.

e frequency of the short tone indicates the type of object (high tones

- non- ferrous metal, low tone - ferrous metal). e number of tones is

set by the user (by default - 4 tones for non-ferrous metals and 1 tone for

ferrous metal).

Each channel has its own independent sensitivity adjustment.

“catch” the object and indicate to the operator that there is something.

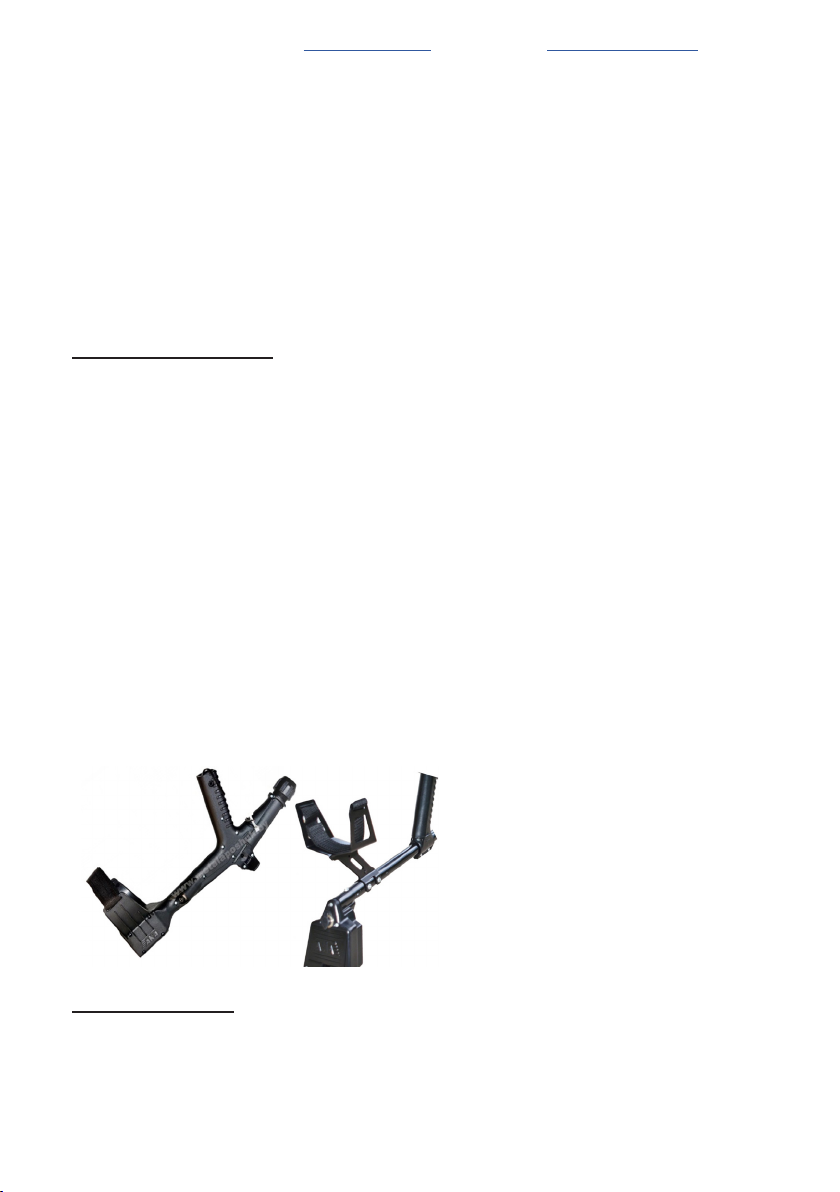

e Signum MFD 7272M GT is equipped with a programmable switch

mode of operation of the sensor at high current (Turbo), which allows to

Departement

of

in

ternational

trade:

https://aka-md.com | +74957991510 | akadetecto[email protected]ere are two-frequency and three-frequen

cy coils of dierent sizes in the assortment

of the company. Frequency switching is

carried out by a toggle switch, which is

located on the coil itself. After switching the

frequency, it is necessary to re-balance the

ground.