General: 01905 823 298 | www.akw-ltd.co.uk6

6

USER CARE

User Care

Shower Seat Use

The shower seat must be used only for the task it is intended to perform.

Do not stand on it or misuse it. This may have serious detrimental effects on its performance

and safety. If any maintenance is required, it must be carried out by a competent installer.

It is advised that this product should be checked as part of a planned maintenance programme.

Children and other users may require supervision when using this product.

Keeping your AKW Shower Seat Clean

This product should be cleaned periodically to remove any accumulation of hair or other waste

material, using normal domestic bathroom cleaning materials. It is important to keep areas

such as seals and moving parts clear from build up of grime and water deposits to maintain

good working order.

Always rinse the shower seat with warm water. After cleaning, always ush down with water

then wipe thoroughly with a damp cloth to remove any cleaning material residues before

drying off.

Disinfecting

Where disinfecting is necessary, standard established procedures for disinfecting equipment

should be used with due care and attention taken of the warnings concerning possible effects

of aggressive chemicals on plastics.

Do not use strong or concentrated acidic, alkaline, or other cleaning materials on an abrasive

pad as these may discolour or damage the product. If more thorough cleaning is needed using

domestic cleaning products always test on a small area rst.

Packaging

Packaging should be disposed of in accordance with local recycling regulations.

Further information

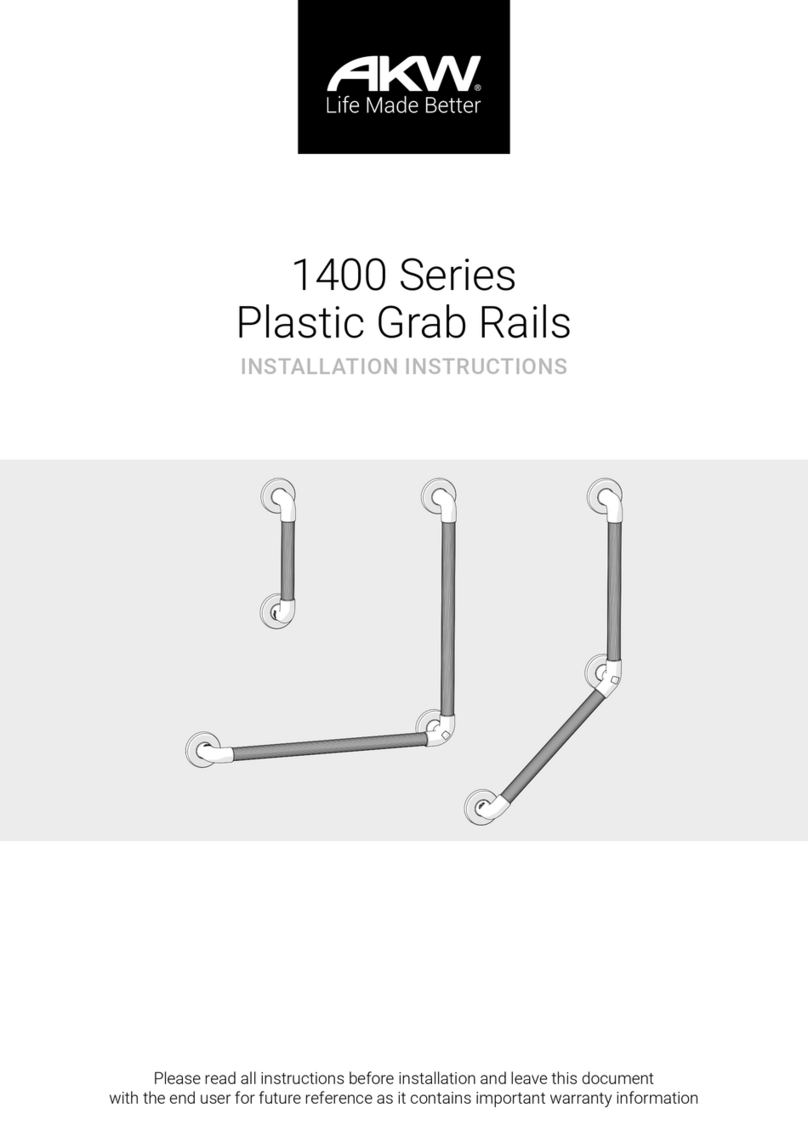

These instructions are provided to advise the minimum standards of installation and

recommend what the best practice for the installation is. Therefore due to the very wide

variability of possible installation conditions, AKW cannot provide all circumstances for the

installation. AKW cannot accept any liability in connection with this information or its use.

This information is provided on the condition that the person receiving it shall make his/her

own tests to determine the suitability for his/her particular purpose. Failure to install this AKW

product in accordance with supplied instructions or the making of unauthorised modications

will invalidate any warranty and may affect product safety. None of the foregoing affects your

statutory rights.