Alamarin Jet AJ 160 User manual

Operation and Maintenance Manual

22

Version 1.5

2

We congratulate You on purchasing a new

alamarin-jet

water jet propulsion unit and

hope that you can enjoy it.

Alamarin-Jet Oy has developed and manufactured water jet propulsion units since 1976.

The propulsion units are used e.g. in pleasure and work boats, as well as in fast rescue

boats with a number of different engines. Thousands of users around the world rely on

the

alamarin-jet

water jet propulsion unit.

The aim of this instruction is to give important information on the operation, use and

maintenance of the unit. We recommend reading this manual carefully before the

implementation of the unit and before You set out to test Your new jet boat for the rst

time. This is how You get the most pleasure and benet out of it.

With best regards,

Alamarin-Jet Oy

Tuomisentie 16

62300 Härmä

Finland

tel. +358-10-7745 260

fax. +358-10-7745 269

www.alamarinjet.com

3 Operation and Maintenance Manual

Version 1.5 Version 1.5

alamarin-jet

water jet propulsion unit

OPERATION AND MAINTENANCE MANUAL

Alamarin-Jet Oy has published this manual in order to guide the owners and users of

boats equipped with

alamarin-jet

water jet propulsion unit.

Alamarin-Jet Oy has published other manuals separately for technical designers,

mechanics and repair men.

From here on in this manual the

alamarin-jet

water jet propulsion unit will be

referred to as ”jet”. This term refers exlusively to a propulsion unit manufactured by

Alamarin-Jet Oy.

The instruction covers the following jet propulsion models:

AJ 160 AJ 180 AJ 185 AJ 230

If the given information is type specic, this will be expressed in the text.

In this manual, clarifying gures will be used.

NOTE - the text includes a warning of a slight danger or a possibility of minor damage to

equipment

HINT - the text includes useful additional information or a hint which facilitates the work

performance or procedure

STOP

!

SERIOUS DANGER - the text includes a warning of danger to life

WARNING - the text includes a warning of a danger that can lead to personal injury, breaking

down of equipment or serious malfunction of equipment

WARRANTY

GUARANTEE MATTER - the text includes a guarantee clause

The symbols used in the manual:

ARROW DESCRIBING MOTION

INDICATOR ARROW

XPART MARKING

Operation and Maintenance Manual

44

Version 1.5

4

After Sales Questionnaire....................................................................................6

Declaration of Incorporation for Partially Completed Machinery .........................8

1. The Jet Propulsion Unit...................................................................................9

2. Operation.......................................................................................................10

2.1. Using for the First Time..........................................................................10

2.2. Steering and Controlling.........................................................................11

...2.2.1. Steering...........................................................................................12

...2.2.2. Controlling.......................................................................................12

2.3. Operating in Shallow Water....................................................................14

2.4. Operating in Reedy Water......................................................................15

2.5. Dry running.............................................................................................16

2.6. Cavitation and Ventilation......................................................................16

...2.6.1. Cavitation........................................................................................16

...2.6.2. Ventilation .......................................................................................17

3. Functions.......................................................................................................18

3.1. Transmission..........................................................................................18

3.2. Bearing...................................................................................................19

3.3. Control System.......................................................................................19

...3.3.1. Electronic Reversing Deector Control System ..............................19

...3.3.2. Hydraulic Reversing Deector Control System...............................20

3.4. Raw Water Cooling ................................................................................22

3.5. Corrosion Protection ..............................................................................22

...3.5.1. Cathodic Protection.........................................................................22

...3.5.2. Painting...........................................................................................23

4. Maintenance..................................................................................................24

4.1. Tools.......................................................................................................24

4.2. Periodical Maintenance..........................................................................24

...4.2.1. Washing the Jet ..............................................................................25

...4.2.2 Lubricating the Bearings..................................................................25

...4.2.3. Lubricating the Control System.......................................................26

...4.2.4 Changing the Zinc Anodes...............................................................27

...4.2.5. Adjusting the Impeller......................................................................27

...4.2.6. Checking the Seals.........................................................................27

...4.2.7. Maintenance of the Hydraulic System ............................................27

4.3. The Impeller ...........................................................................................29

...4.3.1. Removing the Impeller....................................................................31

...4.3.2. Fitting the Impeller ..........................................................................33

5 Operation and Maintenance Manual

Version 1.5 Version 1.5

APPENDIXES

Appendix 1. Maintenance Log............................................................................... 35

Appendix 2. SE-01................................................................................................. 36

Appendix 3. SE-02................................................................................................. 37

Appendix 4. Recommended Greases and Oils and Tightening Torques

of the Screws .................................................................................... 38

Appendix 5. Exploded Views................................................................................. 39

Appendix 6. Warranty & Ownership ...................................................................... 40

AFTER SALES QUESTIONNAIRE

66 6

Version 1.5

AFTER SALES QUESTIONNAIRE

In order to improve our products and operations, we at Alamarin-Jet Oy are

collecting feedback from the end users of water jet propulsion units. This form

is intended to make it as simple as possible for you to give us that feedback.

You can ll out the form in the User’s Manual and send it to us via mail or fax,

or scan and send it via e-mail.

Only answer questions to which you know the answer.

Customer’s/end user’s contact information:

(Boat owner)

Contact information of person answering the questionnaire:

Delivery information of project/device:

(For instance the serial number of the propulsion unit or other relevant

document)

Test information for ALAMARIN-JET:

(Use table on the next page)

Customer service received from retailer/importer/manufacturer prior to

delivery:

(Quotation, technical guidance, documentation, etc.)

Delivery of propulsion unit:

(Timeliness of delivery, contents of delivery, packaging, documentation)

After sales services:

(Include prior experiences of retailer’s/manufacturer’s services)

Spare parts services:

Other comments:

7 AFTER SALES QUESTIONNAIRE

Version 1.5

Version 1.5

Return address: ALAMARIN-JET OY

Tuomisentie 16

FI-62300 HARMA

FINLAND

EUROPE

Fax: 00 358 10 7745 269

E-mail: [email protected]

TEST REPORT Date:

Test weight of boat Number of persons Wind speed m/s Water temperature

Jet serial number Engine and gear GPS/clock Signature

Engine speed Speed in direction 1 Speed in direction 2 Average speed

2400

2500

2600

2700

2800

2900

3000

3100

3200

3300

3400

3500

3600

3700

3800

3900

4000

4100

4200

max rpm

Notes:

If possible, include pictures in your feedback.

Operation and Maintenance Manual

88

Version 1.5

8

DECLARATION OF INCORPORATION FOR PARTIALLY

COMPLETED MACHINERY

(Machinery Directive 2006/42/EC, Annex II, 1.B.)

Manufacturer: Alamarin-Jet Oy

Tuomisentie 16

FI-62300 Härmä, Finland

Compiler of the technical le: Hannu Rantala, Technical Manager

Alamarin-Jet Oy

Tuomisentie 16

FI-62300 Härmä, Finland

Description of the partially completed

machinery: Water jet propulsion device

Operation of the partially completed

machinery: The device is intended to be used as the

propulsion device of a motor boat. A

propulsion device transforms the torque

of the motor into propulsive force.

Model and type of the partially

completed machinery: ____________________________

Serial number of the partially

completed machinery: ____________________________

Alamarin-Jet Oy guarantees that the abovementioned partially completed

machinery meets the requirements of the Machinery Directive (2006/42/EC) and

the validating national regulations.

In addition, the company guarantees that

- the specic technical documents related to the partially completed machinery

have been created according to section B of Annex VII in the Machinery

Directive (2006/42/EC), and

- the following harmonised standards are applied: SFS-EN-ISO 12100-1 and

SFS-EN-ISO 14121-1.

Alamarin-Jet Oy also undertakes to deliver the documents related to the

partially completed machinery to the relevant national authority in electronic

format if so requested.

The partially completed machinery must not be introduced to use before the

nal equipment to which it is intended to be attached has been declared to

conform to the requirements of this Directive.

Place: Kauhava, Finland

__________________________

Date and Signature

9 Operation and Maintenance Manual

Version 1.5 Version 1.5

1. The Jet Propulsion Unit

Alamarin-jet water jet propulsion unit is a single stage axial ow pump, which produces

a high volume ow rate and thrust with high efciency.

The operation of the unit is based on increasing the water ow rate in the nozzle. The

change in the ow rate creates a reacting force in the direction of the ow, which thrusts

the boat forward. By changing the direction of the jet, it is possible to steer the boat in

the desired direction.

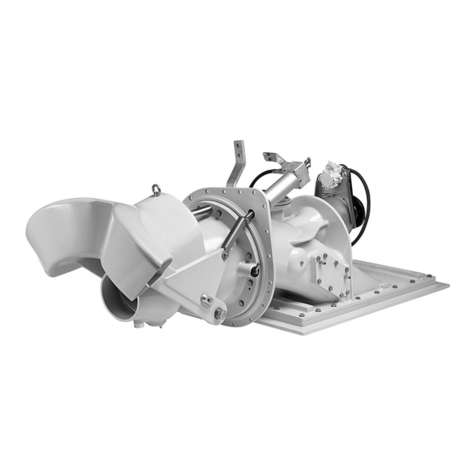

Main Parts (gure 1-1):

The intake duct (A), whose

function is to lead the water from

outside the boat to the intake

side of the impeller with as little

loss as possible and an even

distribution of velocity.

The impeller (B), which is

rotated by the driving motor

through direct drive, increases

the water’s ow rate.

The nozzle converts the pressure

energy produced by the impeller

to motion energy.

The steering device (C) is used

to change the direction of the jet

ow coming out of the nozzle,

which creates the force needed

for turning.

The controlling device (D)

Lowering the reversing deector

causes the boat to reverse. The

direction of the jet ow changes

obliquely forward under the

boat, which is when the thrust

is directed forward and down.

The reversing deector is also

used for stopping the boat. See

section: Steering and Controlling,

page 10

Figure 1-1

B

A

D

C

Operation and Maintenance Manual

1010

Version 1.5

10

Before you set the boat aoat for the rst time, make sure that the jet

has been installed according to the Installation Instruction.

This prevents the emergence of unexpected fault situations which can

lead to damages.

2. Operation

2.1. Using for the First Time

Starting:

In starting an engine equipped with the jet, the following things should be observed:

- The reversing deector control lever must be in centre position.

- The possible gear must be in ”neutral” position.

- In a system without a gear the accelerator must be in ”idle” position.

See the effect of the position of the reversing deector control lever on the position of

the reversing deector on page 11.

Every propulsion unit has its own

serial number. The serial number has

been marked on the type label and in

addition it has been stamped both on

the body of the propulsion unit and on

the inspection hatch cover.

The places in which the serial number

can be found have been designated in

gures 1-2 and 1-3. The serial number

has also been recorded on page 8 of the

Instructions for Use and Maintenance.

Figure 1-2

Figure 1-3

11 Operation and Maintenance Manual

Version 1.5 Version 1.5

When you start the engine for the rst time:

- It may be possible that ”clinking” is heard from the jet during the rst minutes. This

should usually disappear, however, when the impeller gap becomes t.

- The reversing deector’s hydraulic control system needs more oil because the hoses

and cooler are empty. The oil pump noise may be loud at rst, but as the system lls up

with oil the noise disappears. Observe the oil level in the beginning because leakages

cause environmental pollution.

- Checking the oil level has been described in section 3.3.2. The oil type has been given

in appendix 4.

- Ensure the functioning of the system carefully, at low speeds.

- Observe the engine manufacturer’s instructions on running in. The jet does not

require special running in.

- In a system that includes a gearbox, note the direction of the jet´s rotation, which

usually corresponds to the direction of the engine´s rotation (counterclockwise from the

rear of the boat). This is why the gear must usually be used in the ”reverse” position

when you want to engage the propulsion unit´sdrive.

WHEN THE ENGINE IS STARTED UP, THE INTERMEDIATE

SHAFTAND THE MAIN SHAFT START TO ROTATE. AT THIS

STAGE, IT IS NOTALLOWED TO GO NEAR THE ROTATING

PARTS!

THE INSPECTION HATCH MUST BE KEPT CLOSED WHILE

THE ENGINE IS RUNNING!

2.2. Steering and Controlling

IN THIS SECTION, CONTROLLING THE jet boat IS DESCRIBED

IN AWAY THAT IT IS DONE THROUGH ASYSTEM THAT HAS

BEEN INSTALLED AS INTENTED BYTHE MANUFACTURER.

Alamarin-Jet Oy IS NOT LIABLE FOR DAMAGES WHICH

DERIVE FROM INCORRECT INSTALLATION OF THE SYSTEM.

WARRANTY

Steering denotes exclusively moving the steering nozzle. Steering means changing the

boat’s bow angle.

Controlling denotes exclusively moving the reversing deector. Controlling means

changing the boat’s driving direction (forward - astern).

Operation and Maintenance Manual

1212

Version 1.5

12

Figure 2.2.1-1

2.2.1. Steering

The boat is steered by turning the steering wheel. The connection from the wheel to the

steering lever can be either mechanical or hydraulic (gure 2.2.1-1). The lever moves

the nozzle through the shaft and the joint.

- Steering is possible when the power of the jet ow is sufcient. This is why the

engine must run on sufciently high revs when steering. 1200-1800 rpm is a suitable

number of revolutions, depending on the engine.

- In sharp curves, turning the nozzle causes the boat to slow down. This is normal and

increases safety.

- The turning of the nozzle from one extreme position to the other takes ~2 turns of the

wheel.

2.2.2. Controlling

In models AJ 160 andAJ

180/185 a fully mechanical

system can be used, as long as

it is sturdy enough.

The reversing deector can be

lowered in front of the jet ow,

changing its direction forward

and down. There are two

different types of deectors.

Figure 2.2.2-1

Driving direction is controlled with the reversing deector. The reversing deector

is moved with the lever which is usually next to the throttle lever. With this lever, it

is possible to control the hydraulic system mechanically or the mechanical system

electrically.

13 Operation and Maintenance Manual

Version 1.5 Version 1.5

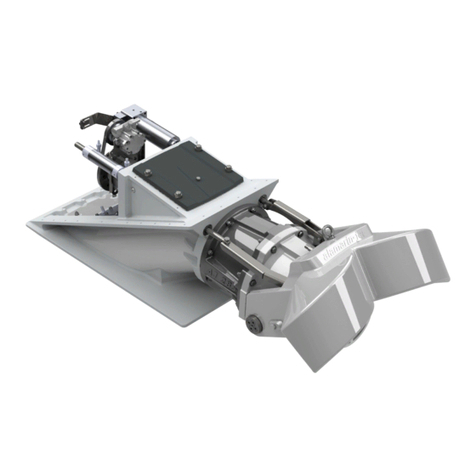

The round type reversing

deector (gure 2.2.2-1) ts in

assemblies in which width is

critical. By using the tube type

reversing deector (gure 2.2.2-

2), a higher reversing power

is attained, but the deector is

wider. The second tube-type

reversing deector model (gure

2.2.2-3) is primarily designed for

twin installations, but it can also

be used for single installations.

Figures 2.2.2-2 and 2.2.2-3

illustrate the hydraulic control

system used in AJ 230.

For models AJ 160 andAJ

180/185, only the round type

reversing deector is available.

Figure 2.2.1-2

When the reversing

deector control lever

is in forward position,

the deector is not

blocking the jet ow

and the boat moves

forward (gure 2.2.2-

4).

When the lever is

in the rear position

(gure 2.2.2-5), the

deector is in front of

the jet ow and the

boat moves astern.

Figure 2.2.2-3

Figure 2.2.2-4

Figure 2.2.2-5

Operation and Maintenance Manual

1414

Version 1.5

14

The centre position of the reversing deector corresponds to gear’s ”idle” position; even

though the drive is on, the boat stays still. The centre position is not absolute, it depends

on the power of the jet ow. Finding the centre position is done by testing during the

rst driving hours.

When moving at low speeds, the reversing deector is used to control the boat’s speed.

Because the engine is being run at 1200-1800 rpm to enhance steering, the boat may

travel faster than desired. In this case the deector is lowered in front of the jet ow

to reduce the thrust directed towards the driving direction. Steerability remains good

however.

At high speeds, the deector is not used to reduce speed. Instead, speed is controlled

with engine revolution.

It is possible to turn the boat in place when the deector is in centre position. When the

nozzle is turned to the desired direction, the boat rotates about its central axis.

When reversing, steering is inversed in comparison to driving forward. If you want to

turn the boat to the left, the wheel must be turned to the right. A good mnemonic is that

the boat’s bow always turns in the same direction as the wheel.

When fast turns are needed, the engine revolutions are not reduced, but instead the turn

is done through combined motion of the nozzle and the deector.

Figure 2.3-1

2.3. Operating in Shallow Water

The jet boat can be used in very shallow water, but it must be taken into account that

especially on high revolutions the suction power of the intake is high (cf. gure 2.3-1).

Loose objects may get sucked into the intake screen and small objects wash through the

jet. Stones may cause damage. In sandy conditions wearing inevitably takes place. The

maintenance procedures required by a worn impeller are described in the maintenance

section of this manual. See Adjusting and Fitting the Impeller, page 24.

15 Operation and Maintenance Manual

Version 1.5 Version 1.5

At planing speeds, a jet boat usually crosses reed elds without difculty. In difcult

conditions however, clogging may be possible. In boats equipped with a gear box,

cleaning the intake duct is easy because at reverse gear, a back ow is created in the

duct.

2.4. Operating in Reedy Water

THE JET HAS BEEN DESIGNED TO RUN ON REVERSE GEAR

ONLY MOMENTARILYAND ON LOW REVOLUTIONS.A TOO

HEAVY LOAD ON REVERSE GEAR CAN LEAD TO JAMMING

OF THE IMPELLER OR BREAKING DOWN OF HYDRAULICS!

Figure 2.4-1

If clogging occurs on a boat that does not have a gear box, the following procedures are

recommended:

1. Stop the engine. This causes the extraneous objects in the grass rake simply to

drop off.

2. Let the engine run on high revolutions for a few times. This often sucks the

extraneous objects through the jet and cleans it.

3. If the boat is moving forward, raise the boat speed as much as possible and then

shut down the engine. The speed of the boat often sweeps the grass rake clean.

4. Drive the boat on reverse as fast as possible. As the boat moves astern, shut

down the engine and move the deector control lever to forward position.

This causes water to ow backwards through the jet and usually opens any

blockage whatsoever.

The sleeve shown in gure 2.4-1 on the axle has a left-handed threading. If the engine is

run at too high revolutions on reverse gear, the sleeve may loosen and the impeller may

get stuck against the duct walls.

Operation and Maintenance Manual

1616

Version 1.5

16

Figure 2.4-2

The most common malfunction in water jet propulsion units manifests as cavitation.

Engine overdrive and stopping of thrust are signs of this.

Cavitation is a phenomenon in which the water pressure decreases locally in such an

extent that water vaporizes on the surface of the impeller blade, creating steam bubbles.

The bubbles move on the surface of the blade and when they reach a higher pressure

area they collapse. Cavitation incurs considerable reduction in capacity and damages the

impeller.

Usually the cause is the reduction of pressure in the whole intake duct, which is induced

by a blockage.

Cavitation can often be heard as a rumbling sound.

Any factor that hinders the ow of water in the jet increases the chance of cavitation.

The jet may be run by the engine even out of the water, because the bearings are greased

and oiled. This is a signicant benet in comparison to water-lubricated bearings,

which do not sustain dry running well. During dry runs, a temporary water inlet must be

arranged for the motor sea water cycle to cool the engine.

With these simple instructions it is

possible practically without exception

to clean the jet even after the boat has

stopped completely in reedy water.

Unlike with other propulsions, in boats

equipped with the jet the engine stops

very rarely as a result of a reed blockage.

If the measures mentioned above are

not of help, the propulsion is equipped

with an inspection hatch (gure 2.4-2),

through which the blockage can be seen

and removed.

Remember to close the hatch! The wing screw is tightened by hand!

2.6. Cavitation and Ventilation

2.5. Dry running

2.6.1. Cavitation

17 Operation and Maintenance Manual

Version 1.5 Version 1.5

If cavitation is apparent, the following things

should be checked.

Check through the inspection hatch that:

1. The grass rake (gure 2.6.1-1) is not

clogged (by grass, reed, plastic, stones etc.).

2. There are no extraneous objects in the stator

or nozzle unit or the impeller (gure 2.6.1-2)

(rope, reed entagled in the drive shaft, stones

in the outlet port)

3. The impeller (gure 2.6.1-3) is not

damaged. It should be smooth and it should

not have any sharp cuts.

If the boat runs slowly even though the engine

runs on high revolutions, nd out the cause.

Ventilation produces similar symptoms as cavitation but is caused by different reasons.

Ventilation is created when air gets to drift into the intake duct. The air causes the

impeller to lose grip and the thrust weakens. Ventilation can be heard as a similar sound

as cavitation.

Ventilation can be caused e.g. by the following things:

- The inspection hatch cover is open or a seal is damaged.

- The installation height of the jet is wrong, air is allowed to pass along the surface of

the cavitation plate into the intake duct.

- During installation, places accordant with the instructions have not been sealed.

Figure 2.6.1-1

Figure 2.6.1-2

Figure 2.6.1-3

2.6.2. Ventilation

Operation and Maintenance Manual

1818

Version 1.5

18

3. Functions

3.1. Transmission

The jet takes its propulsion power from a petrol or a diesel engine. The most common

way to transmit the power is through a 1:1 gear box, but direct drive is also possible

and functional. The greatest benets of a gear box are a real neutral gear and an intake

duct backush.

In the direct drive or so-called bobtail installation it is commendable to use a ywheel

adapter provided by the engine manufacturer. It protects the ywheel from mechanical

damages and e.g. corrosion.

The auxiliary shaft which is connected between the jet and the engine usually depends

on the boat manufacturer. If necessary, the jet manufacturer supplies the auxiliary shaft

with the propulsion unit. It is also possible to get instructions and recommendations

from the manufacturer on which auxiliary shaft to use. In the end, the shaft

manufacturer gives instructions on the installation and maintenance of the shaft. Below

is a list of example shafts which have been used with the jet.

1. Constant velocity shaft

- Joint structure based on balls rolling on a spherical surface.

2. Cardan shaft

- Joint structure based on pivoted grids.

3. Silent block shaft

- Joint structure based on an elastic rubber element

THE AUXILIARY SHAFT MUSTABSOLUTELY BE OF

HIGH ENOUGH QUALITYAND PROPERLY BALANCED. A

POOR SHAFT CAN CAUSE EXCESSIVE DAMAGE TO THE

PROPULSION UNIT.

THE ALIGNMENT OF THE AUXILIARY SHAFT MUST BE KEPT

ACCURATE. IT MUST BE CHECKED AT LEAST ONCE EVERY

DRIVING SEASON (YEAR).

19 Operation and Maintenance Manual

Version 1.5 Version 1.5

The jet’s bearing is very simple (gure 3.2-1). There are bearings at both ends of the

direct shaft. The structure of the front bearing (A) is receptive to axial pressure. In

addition, at the front end there is the supporting bearing (B) of the coupling ange and

the auxiliary shaft.

Rolling type bearing is used at the front end and slide bearings are used at the rear (C).

Both bearings are stock grease lubricated. It is possible to install a water lubricated

bearing at the rear end.

B

A

C

Figure 3.2-1

3.3. Control System

The system is available for models AJ 160, AJ 180 and AJ 185.

The main components that the system consists of are #1 a control lever (potentiometer),

#3 an electronics unit and #4 a spindle motor. See gure SE-01 in Appendixes.

The electronics unit changes the position of the lever into a signal to to the spindle

motor.

The repair and adjustment instructions for the system can be found in Repair Manual 1.

3.3.1. Electronic Reversing Deector Control System

3.2. Bearing

Lubricate front bearings every 50 hours or twice a year at minimum. The bearings are

lubricated through the hose in the engine room.

The boat should be lifted out of water when lubricating the rear bearings. It is advisable

to add grease to the rear bearings whenever the boat is lifted out of water. At minimum,

however, this should be done every 100 hours or twice a year.

Operation and Maintenance Manual

2020

Version 1.5

20

Figure 3.3.2-1

3.3.2. Hydraulic Reversing Deector Control System

The system is available for AJ 230. It includes a rotary valve which simplies the

system considerably.

The reversing deector is controlled (cf. gure 3.3.2-1) mechanically with a cable (A)

which operates the valve regulator (B).

The cylinder gets its power from the oil pump which has been integrated in the

propulsion unit.

In a stock delivery, the system does not include a control lever or a cable, so their type

varies depending on the boat manufacturer. However, the different types of systems

have the following things in common:

- The operation of the deector must be separate from the throttle and the gear.

- The stroke length of the cylinder is always the same.

- The incoming direction of the cable can be chosen freely.

The oil circulating in the system must be cooled in order to prevent excessive heating.

This is done with a separate heat exchanger or a possible cooler in the engine.

B

A

This manual suits for next models

3

Table of contents

Other Alamarin Jet Marine Equipment manuals