European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH www.e2s.com Tel: +44 (0)208 743 8880

Document No. D190-00-301-IS Issue 2 17-03-2022 Sheet 2 of 9

2) Warnings

CAUTION

TO REDUCE THE RISK OF IGNITION OF HAZARDOUS

ATMOSPHERES:

DISCONNECT FROM SUPPLY BEFORE OPENING.

KEEP TIGHTLY CLOSED WHEN IN OPERATION.

WARNING

FIT SEALING FITTING IN CONDUIT RUNS WITHIN 18 INCHES

FROM ENCLOSURE.

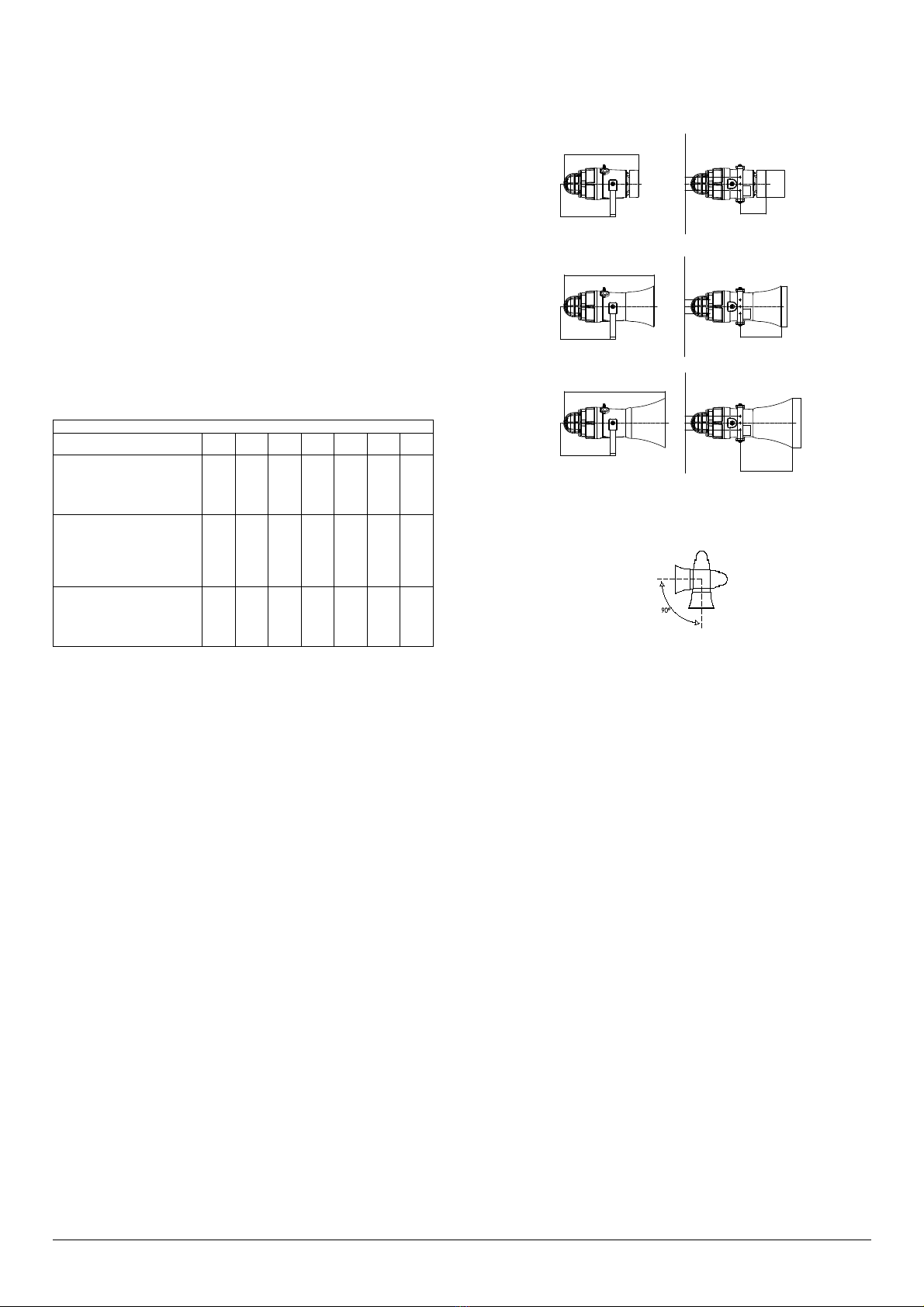

EQUIPMENT MUST NOT BE INSTALLED WITH THE HORN FACING

UPWARDS OF HORIZONTAL

DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS

PRESENT

DO NOT OPEN WHEN ENERGISED

POTENTIAL ELECTROSTATIC CHARGING HAZARD - CLEAN

ONLY WITH A DAMP CLOTH

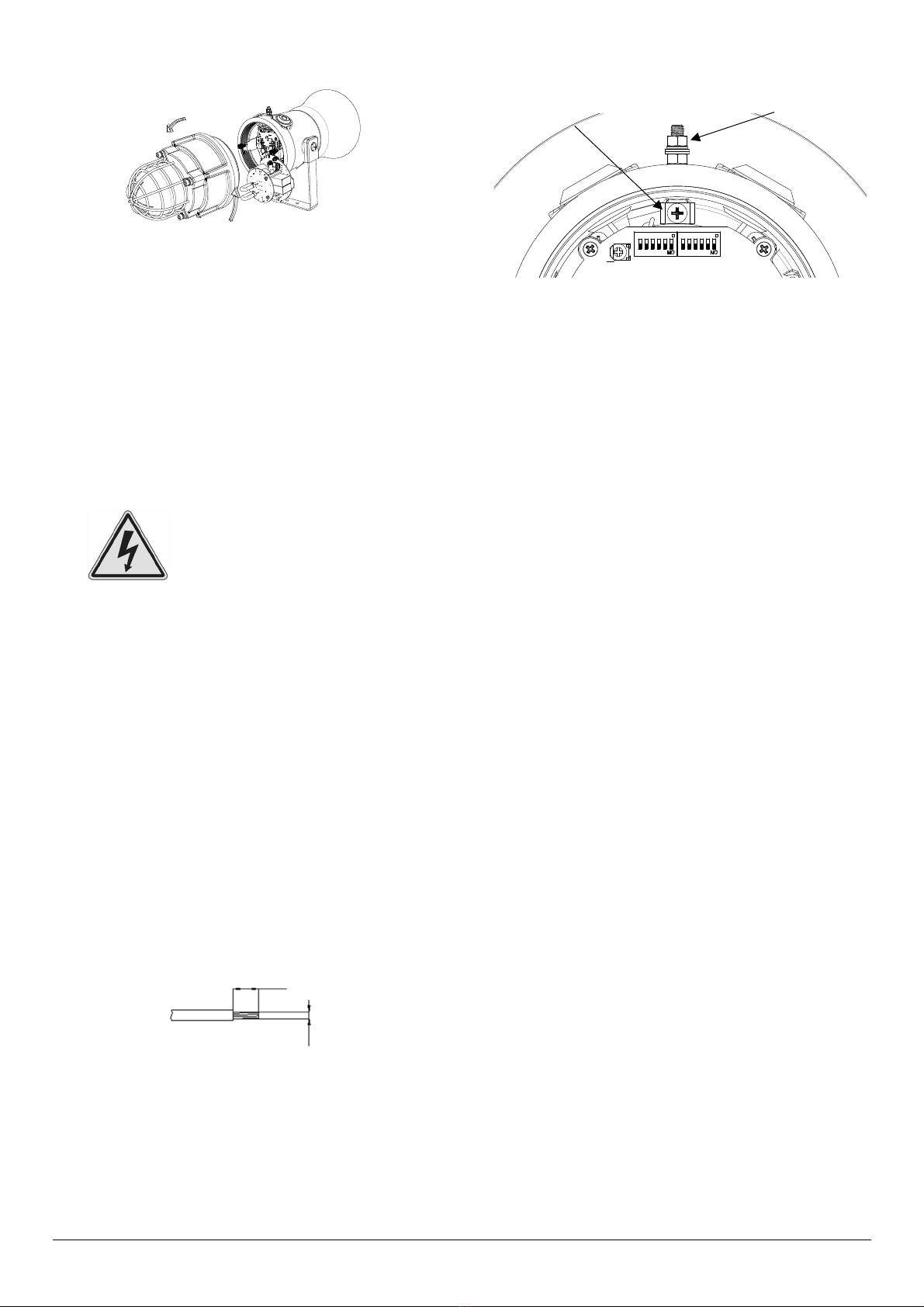

ENCLOSURE ENTRIES: TWIN M20 X 1.5 / SINGLE 1/2” NPT

ATEX/IECEx & UKEx INSTALLATIONS: IF TEMPERATURE

EXCEEDS 70°C AT ENTRY OR 80°C AT BRANCHING POINT USE

SUITABLE RATED CABLE AND GLANDS

ATTENTION

POUR REDUIRE LE RISQUE D’INFLAMMATION DES

ATMOSPHÈRES DANGEREUSES :

COUPER L 'ALIMENTATION AVANT OUVERTURE.

CONSERVER FERMÉ PENDANT LE FONCIONNEMENT.

AVERTISSEMENT

CONDUITS DOIVENT ETRE SCELLES EN MOINS DE 18 POUCES.

ÉQUIPEMENT NE DOIT PAS ETRE INSTALLE AVEC LE KLAXON

TOURNEE VERS LE HAUT DE HORIZONTAL.

NE PAS OUVRIR UN PRESENCE D’ATMOSPHERE EXPLOSIVE

NE PAS OUVRIR ENERGIE

DANGER POTENTIEL CHARGE ÉLECTROSTATIQUE - NETTOYER

UNIQUEMENT AVEC UN CHIFFON HUMIDE

ENTRÉES DE BOÎTIER: 2 x M20 X 1.5 / 1 x 1/2” NPT

ATEX/IECEx & UKEx INSTALLATIONS : SI LA TEMPÉRATURE

DÉPASSE 70 °C À L'ENTRÉE OU 80 °C AU POINT DE

BRANCHEMENT, UTILISER UN CÂBLE ET DES JOINTS

D'ÉTANCHÉITÉ APPROPRIÉS

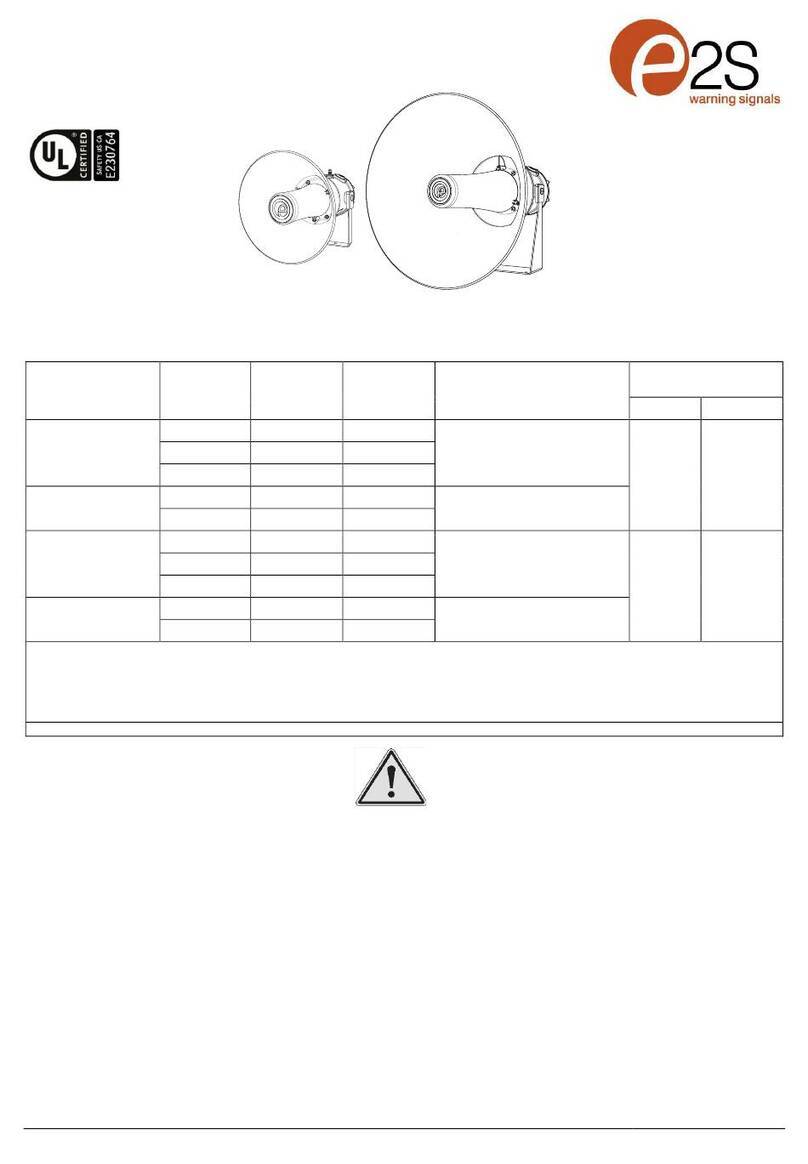

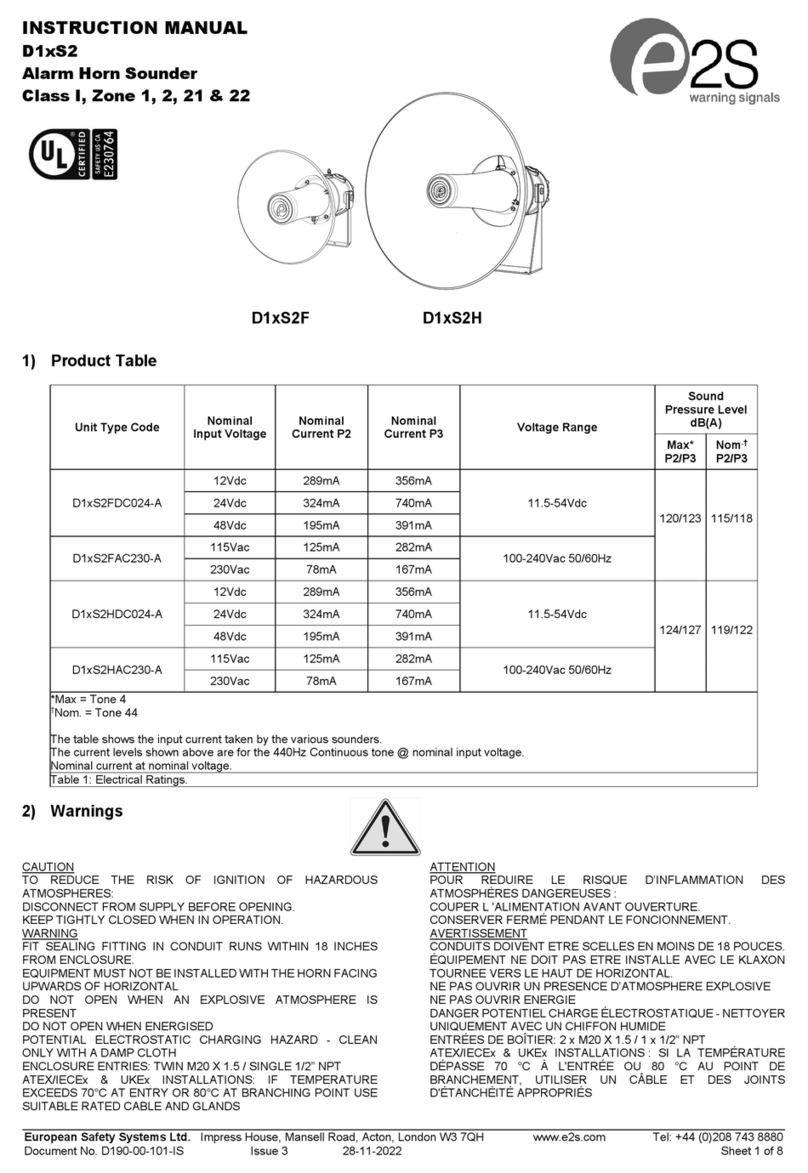

3) Marking & Rating Information

The D1xS1 Alarm Horns comply with the following standards for

hazardous locations:

3.1 Class/Division Ratings for US & Canada

Standards

Class I UL 1203 & CSA C22.2 No 30-M1986

Class Division Ratings for US (NEC)

Model No: Rating

D1xC1X05-DC024-A/

D1xC2X05-DC024-A

Class I Div 1 ABCD T4 Ta -55°C to +85°C

Class I Div 1 ABCD T4A Ta -55°C to +80°C

Class I Div 1 ABCD T5 Ta -55°C to +60°C

Class I Div 1 ABCD T6 Ta -55°C to +45°C

D1xC1X05-AC115-A/

D1xC2X05-AC115-A/

D1xC1X05-AC230-A/

D1xC2X05-AC230-A/

Class I Div 1 ABCD T4 Ta -55°C to +85°C

Class I Div 1 ABCD T4A Ta -55°C to +70°C

Class I Div 1 ABCD T5 Ta -55°C to +50°C

D1xC1X10-DC024-A/

D1xC2X10-DC024-A

Class I Div 1 ABCD T3C Ta -55°C to +85°C

Class I Div 1 ABCD T4 Ta -55°C to +70°C

Class I Div 1 ABCD T4A Ta -55°C to +55°C

D1xC1X10-AC115-A/

D1xC2X10-AC115-A/

D1xC1X10-AC230-A/

D1xC2X10-AC230-A/

Class I Div 1 ABCD T3C Ta -55°C to +85°C

Class I Div 1 ABCD T4 Ta -55°C to +65°C

Class I Div 1 ABCD T4A Ta -55°C to +50°C

Class Division Ratings for Canada (CEC)

Model No: Rating

D1xC1X05-DC024-A/

D1xC2X05-DC024-A

Class I Div 1 ABCD T5 Ta -55°C to +55°C

Class I Div 1 ABCD T6 Ta -55°C to +45°C

D1xC1X10-DC024-A/

D1xC2X10-DC024-A

Class I Div 1 ABCD T4A Ta -55°C to +55°C

Class Zone Ratings for US (NEC)

Model No: Rating

D1xC1X05-DC024-A/

D1xC2X05-DC024-A

Class I Zone 1 IIC T4 Ta -55°C to +85°C

Class I Zone 1 IIC T4A Ta -55°C to +80°C

Class I Zone 1 IIC T5 Ta -55°C to +60°C

Class I Zone 1 IIC T6 Ta -55°C to +45°C

D1xC1X05-AC115-A/

D1xC2X05-AC115-A/

D1xC1X05-AC230-A/

D1xC2X05-AC230-A/

Class I Zone 1 IIC T4 Ta -55°C to +85°C

Class I Zone 1 IIC T4A Ta -55°C to +70°C

Class I Zone 1 IIC T5 Ta -55°C to +50°C

D1xC1X10-DC024-A/

D1xC2X10-DC024-A

Class I Zone 1 IIC T3C Ta -55°C to +85°C

Class I Zone 1 IIC T4 Ta -55°C to +70°C

Class I Zone 1 IIC T4A Ta -55°C to +55°C

D1xC1X10-AC115-A/

D1xC2X10-AC115-A/

D1xC1X10-AC230-A/

D1xC2X10-AC230-A/

Class I Zone 1 IIC T3C Ta -55°C to +85°C

Class I Zone 1 IIC T4 Ta -55°C to +65°C

Class I Zone 1 IIC T4A Ta -55°C to +50°C

Class Zone Ratings for Canada (CEC)

Model No: Rating

D1xC1X05-DC024-A/

D1xC2X05-DC024-A

Class I Zone 1 IIC T5 Ta -55°C to +55°C

Class I Zone 1 IIC T6 Ta -55°C to +45°C

D1xC1X10-DC024-A/

D1xC2X10-DC024-A

Class I Zone 1 IIC T4A Ta -55°C to +55°C

Installation must be carried out in compliance with the National

Electric Code / Canadian Electric Code

3.2 ATEX / IECEx & UKEx Ratings

Standards

EN60079-0:2018/IEC60079-0:2017 (ed.7): Explosive Atmospheres -

Equipment General Requirements.

EN60079-1:2014/IEC60079-1:2014 (ed.7): Explosive Atmospheres -

Equipment Protection by Flameproof Enclosures “d”.

EN60079-31:2014/IEC60079-31:2013 (ed.2): Explosive Atmospheres -

Equipment Dust Ignition Protection by enclosure

“t”.

Model No: Rating

D1xC1X05-DC024-A/

D1xC2X05-DC024-A

Ex db IIC T4 Gb Ta –55°C to +75°C

Ex db IIC T5 Gb Ta –55°C to +55°C

Ex db IIC T6 Gb Ta –55°C to +40°C

Ex tb IIIC T115°C Db Ta

55°C to +75°C

D1xC1X05-AC115-A/

D1xC2X05-AC115-A/

D1xC1X05-AC230-A/

D1xC2X05-AC230-A/

Ex db IIC T4 Gb Ta –55°C to +75°C

Ex db IIC T5 Gb Ta –55°C to +45°C

Ex tb IIIC T122°C Db Ta –55°C to +75°C

D1xC1X10-DC024-A/

D1xC2X10-DC024-A

Ex db IIC T3 Gb Ta –55°C to +75°C

Ex db IIC T4 Gb Ta –55°C to +65°C

Ex tb IIIC T137°C Db Ta

55°C to +75°C

D1xC1X10-AC115-A/

D1xC2X10-AC115-A/

D1xC1X10-AC230-A/

D1xC2X10-AC230-A/

Ex db IIC T3 Gb Ta –55°C to +75°C

Ex db IIC T4 Gb Ta –55°C to +60°C

Ex tb IIIC T145°C Db Ta –55°C to +75°C

See Product table for electrical ratings of each unit model

Certificate No. DEMKO 19ATEX2141X

IECEx ULD 19.0008X

UKEx UL UL21UKEX2132X

Epsilon x

Equipment Group

and Category:

II 2G

II 2D

CE Marking and

Notified Body No. 2813

UKCA Marking and

Notified Body No. 0518