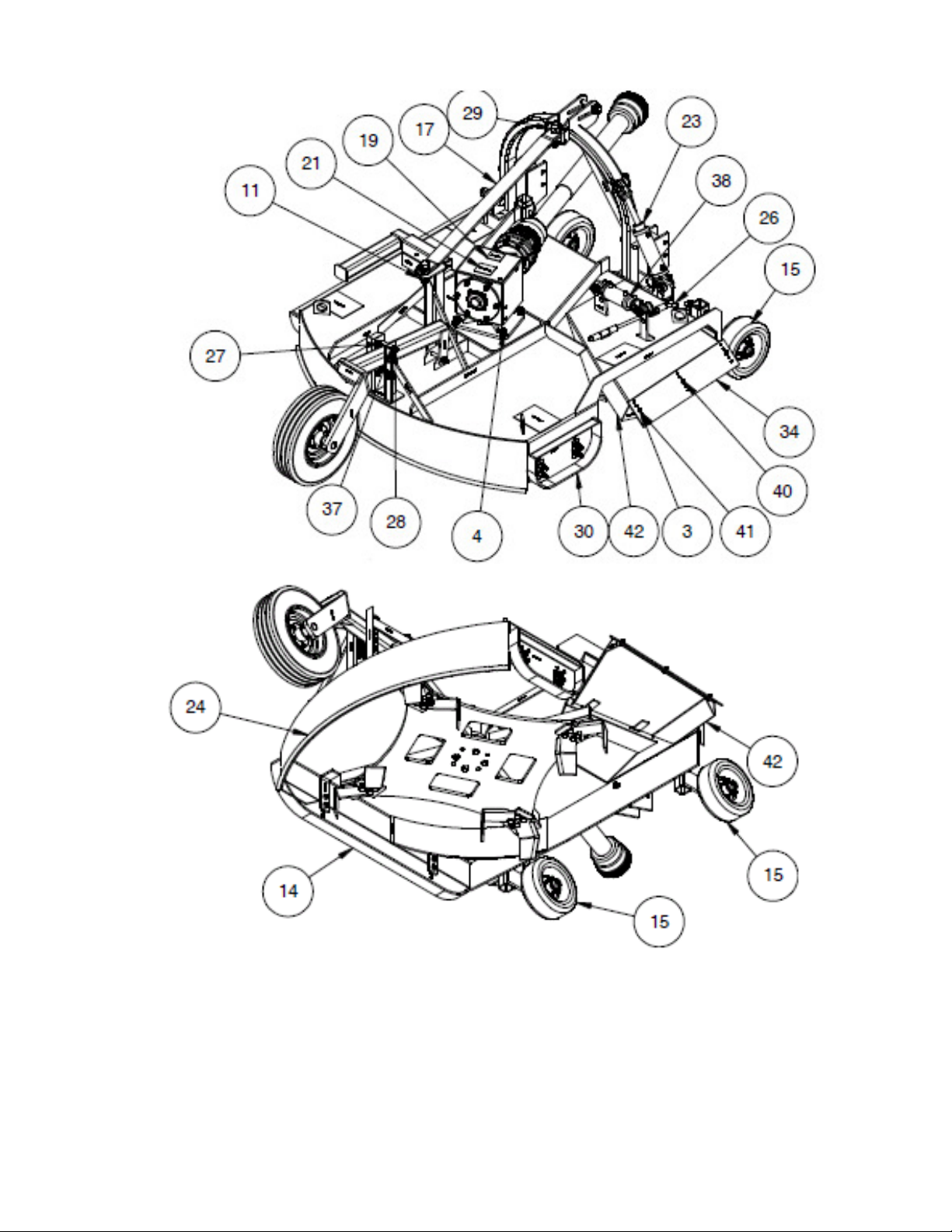

18

S08400 LXSP 5 SOIL PROFILER BODY COMPLETE

REVISION A FROM 012/2014

REF NO PART NO QTY DESCRIPTION

1 S08428-1 1 TOWER ASSEMBLY

2 S03546 1 HEX BOLT 5/8 UNC X 5 ½” LONG

3 S01025 3 HEX NUT 3/8 UNC

4 S03389 4 HEX BOLT ¾ UNF X 2 ¼” LONG

5 S04245 4 SPRING WASHER 3/4”

6 S05629 8 SKID TAB

7 S08432 1 CASTOR BEAM AND WHEEL ASSEMBLY

8 S03581 1 HEX BOLT 1” UNC X 5” LONG

9 MI00034-1 1 DECAL “SUPERIOR” (BIG)

10 ST07282 1 SERIAL NUMBER PLATE

11 S01039 3 NYLOC NUT 1 UNC

12 S08436 1 PROFILING HEAD ASSEMBLY

13 S08471 1 GEARBOX ASSEMBLY

14 S04370 1 ADJUSTABLE SKID WITH 30” HOLE CENTRE

15 S08431 2 FRONT WHEEL ASSEMBLY COMPLETE

16 S04133 3 CAT 1 TOP LINK PIN ¾ DIA

17 S08429 1 STAY BAR ASSEMBLY

18 S03545 1 HEX BOLT 5/8 UNC X 5” LONG

19 MI00034-6 1 DECAL “ROTATING DRIVELINE”

20 S01804 3 HEAVY FLAT WASHER 1”

21 MI00034-2 1 DECAL “CHECK OIL LEVEL”

22 S03539 8 HEX BOLT 5/8 UNC X 2 ½” LONG

23 S08406 1 HYD CYLINDER 6” STROKE 1 ½” BORE

24 S08420 1 SOIL PROFILER BODY FABRICATION

25 S08426 1 SAFETY LEG ASSEMBLY

26 S08422 1 CONTROL FLAP PIN

27 S03544 1 BOLT UNC 5/8 UNC X 4 ½” LONG

28 S01033 11 NYLOC NUT 5/8 UNC

29 S02262 2 HEX HD BOLT 1” UNC X 4” LONG

30 S08425 1 ADJUSTABLE SKID SHORT

31 S04011 3 LYNCH PIN

33 S07222 1 DRIVESHAFT COMPLETE 8 SERIES

34 MI00034-3 1 DECAL “KEEP CLEAR OPEN DISCHARGE”

35 S08423 1 CONTROL FLAP EXTENSION

36 MI00034-13 3 DECAL “MANUFACTURED BY”

37 S04225 4 WASHER 5/8”

38 S08405 10 HYDRAULIC CYLINDER 4” STROKE

39 S09087 1 CLUTCH ASSEMBLY

40 S03478 3 HEX BOLT 3/8 UNC X 1” LONG

41 S04242 3 SPRING WASHER 3/8”

42 S08416 1 CHUTE FLAT WELDMENT

43 ST02220 2 SHORT SKID LEG

S07497 1 CAT II TOWER TOP LINK CHAIN