BURCHLAND

2Burchland Mfg

Table Of Contents

Safety Instructions .............................................................................................. 4

Signal Words ...............................................................................................................4

General Safety Instructions .........................................................................................5

Start-Up Safety ............................................................................................................5

Operation Safety..........................................................................................................5

Transport Safety ..........................................................................................................6

Storage Safety.............................................................................................................6

Service and Maintenance Safety.................................................................................6

Hydraulic Safety ..........................................................................................................7

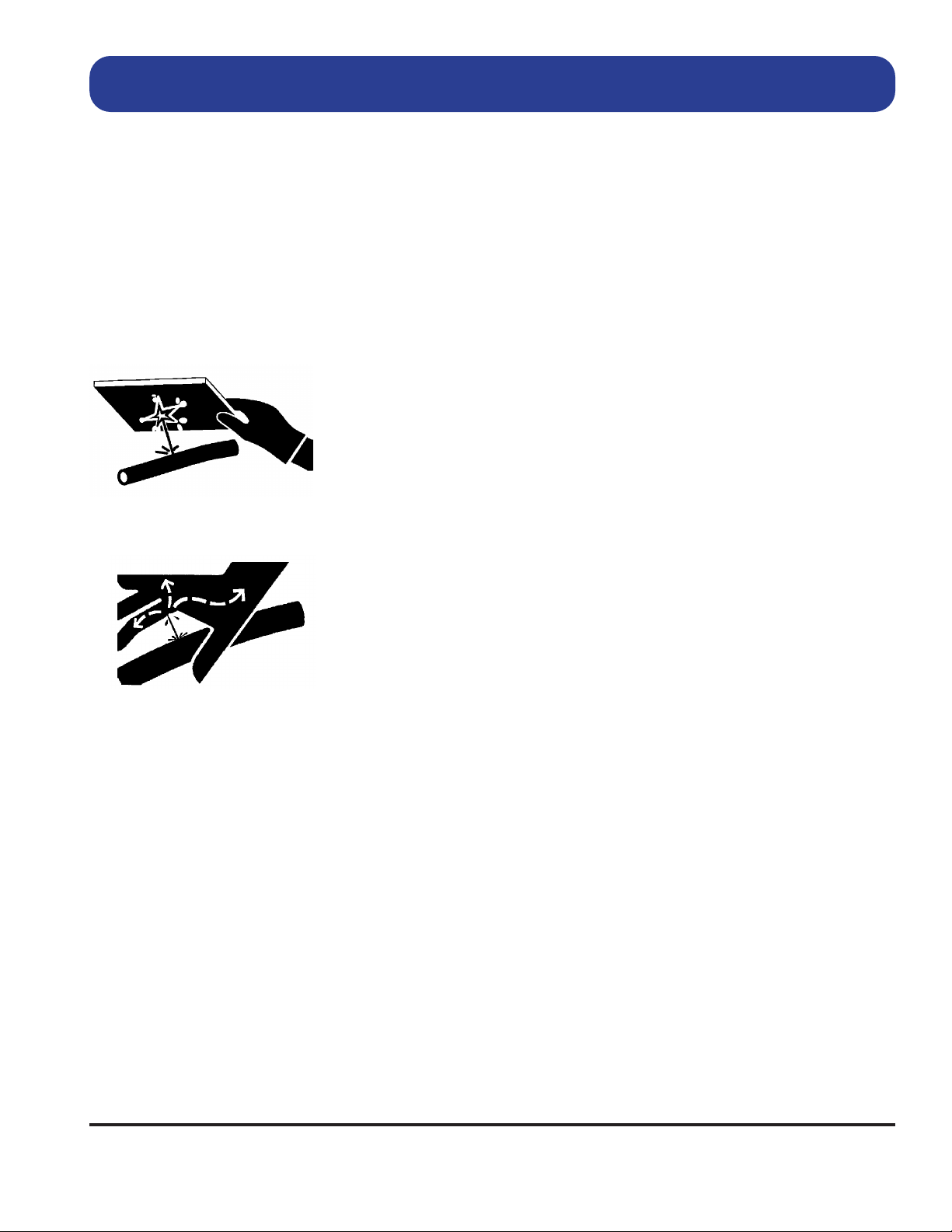

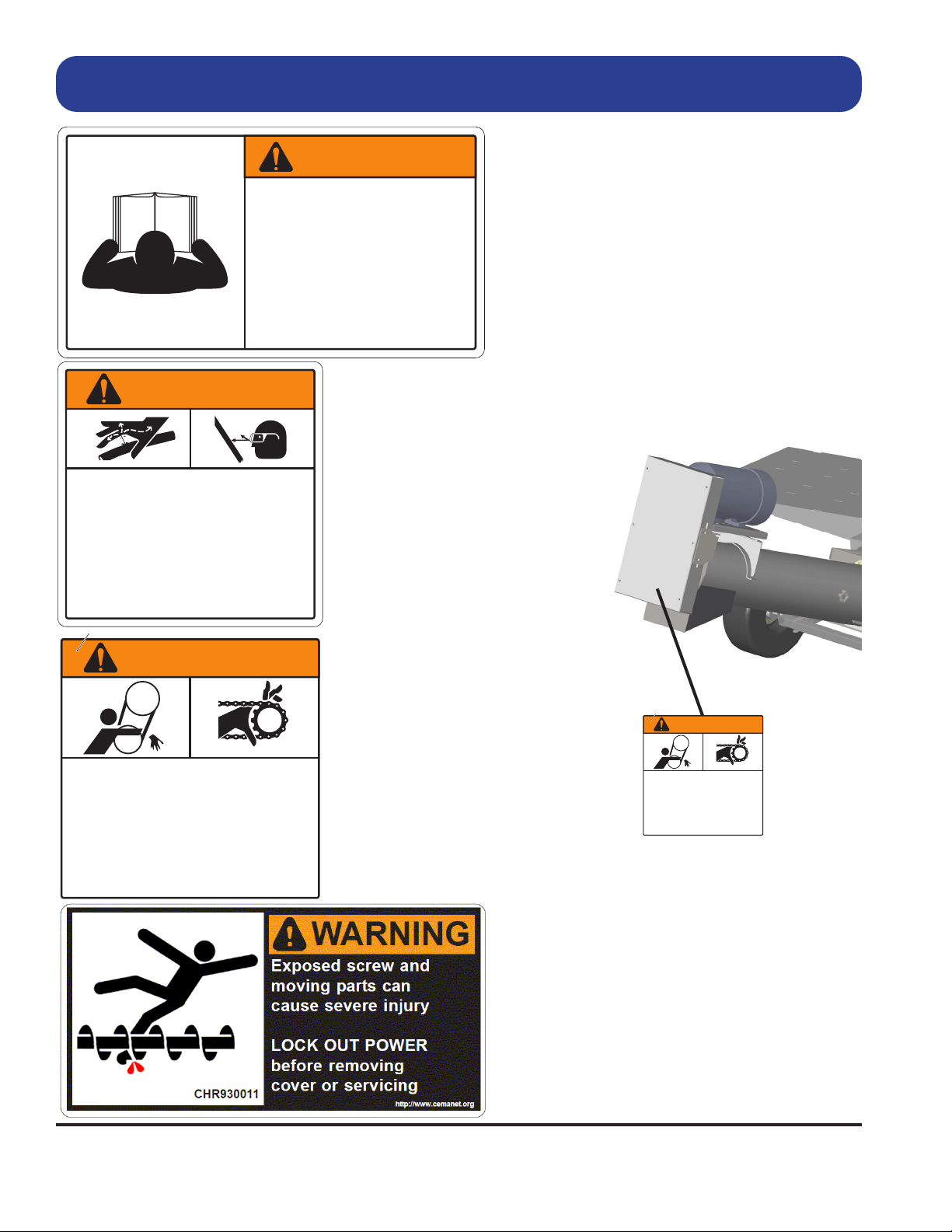

Safety Decals ..............................................................................................................7

Decal Installation ......................................................................................................7-8

Safety Decal Placement ..............................................................................................9

Operation Instructions...................................................................................... 10

Hydraulic System Requirements ...............................................................................10

Electric System Requirements ..................................................................................10

Preparing the Machine for Operation from Transport Mode (Manual Lift) ............10-12

Preparing the Machine for Operation from Transport Mode (Hydraulic Lift).........12-13

Unloading ..................................................................................................................14

Starting (Hydraulic Drive Models)..............................................................................15

Starting (Electric Drive Models) .................................................................................15

Shutdown...................................................................................................................16

Preparing the Machine for Transport from Operation Mode .................................16-18

Cleanout ....................................................................................................................19

Storage ......................................................................................................................20

Maintenance Instructions .............................................................................................21

Lubrication .................................................................................................................21

Servicing the Drive Chains ........................................................................................22

Wheel Bearings .........................................................................................................22

Wheel Nut Torque......................................................................................................22

U-Joint and Sprocket Set Screws..............................................................................22

Mounting Bolts and Hardware ...................................................................................23

Warranty ............................................................................................................. 24

Warranty Registration Card .......................................................................................25