MAINTENANCE GUIDE

Dear Customer,

We thank you for choosing an Agrital cab!

Here’s a reference guide for the most common maintenance operation you’ll be performing to

maintain your new cab efficient and in good state.

CLEANING

To clean the interior, we suggest to remove the carpets and clean the separately, in order not

to leave them wet. The fixed linings can be cleaned with simple water.

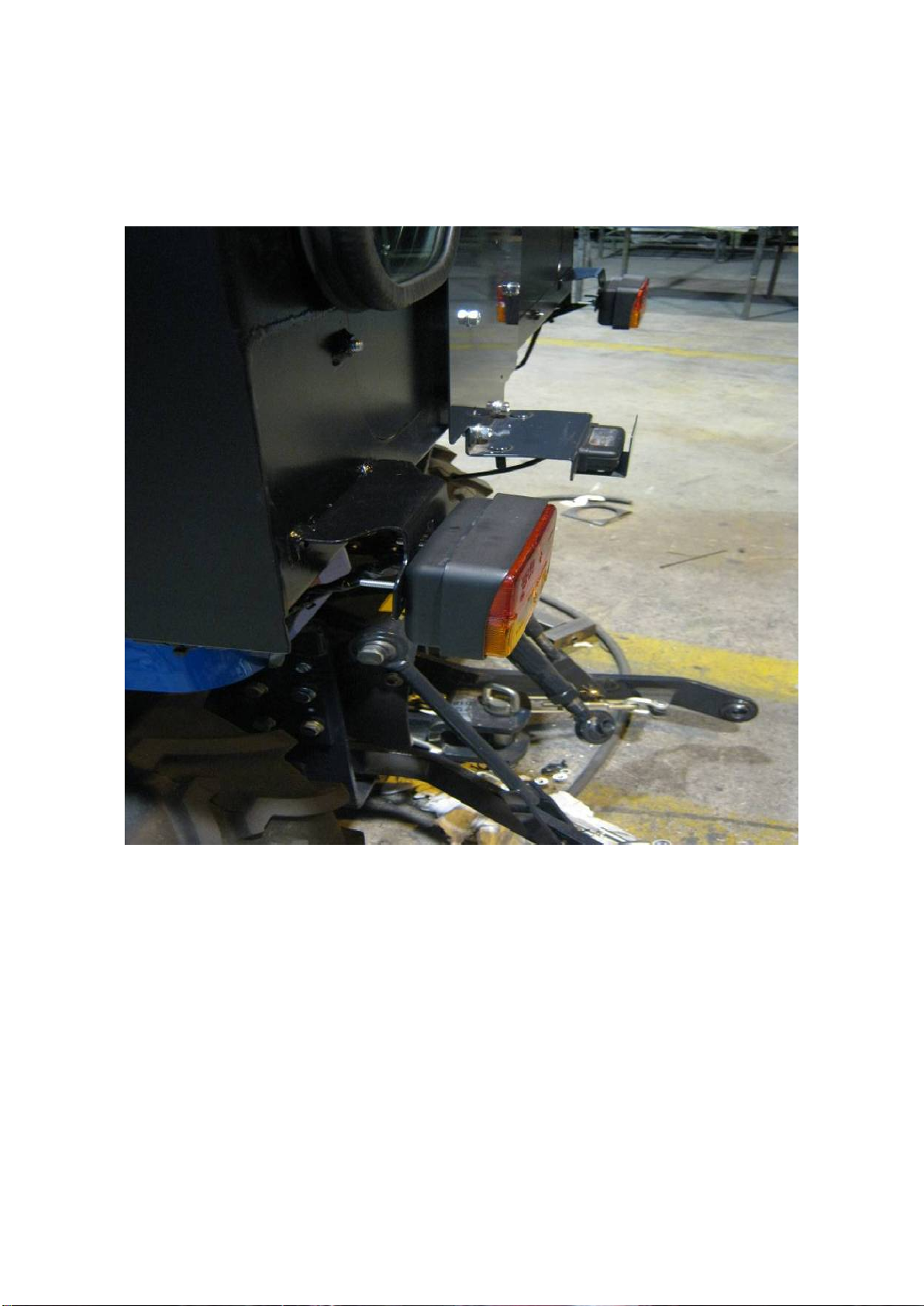

DOOR ADJUSTMENT

After having installed your new cab, you may need to adjust the door locking by adjusting the

attachment of the door latch. This operation must be carried on each time the cab is

mounted.

To maintain a good efficiency of the locks, we strongly suggest not to operate the tractor with

the doors opes, since the vibrations could damage the hinges.

HEATING/VENTILATION SYSTEM (water-cooled tractors only)

In order to switch from the heating to the simple ventilation, the operator has to turn off the

hydraulic outlet tap inside the cab.

CLEANING AND CHANGING THE AIR FILTERS

We suggest to clean the intake air filter every 150 working hours with compressed air or a

vacuum cleaner.

After 1000 working hours, we suggest to completely clean the air system by using

compressed air. To access the system remove the roof (the silicone will have to be removed

as well). We suggest to put new silicone back when mounting the roof again.

We suggest to change the air filter once a year.

Carbon activated filters have a very limited life span. We suggest to use them only when

dealing with special chemical treatments and to use a standard filter for other operations.

Store the activated carbon filter in its package when not in use.

The life span of the filter depends on the working conditions. The mean life span is about 150

working hour

AIR CONDITIONING SYSTEM

To keep the air conditioning effective, please remember to clean the radiator on the roof and

keep the gas on the compressor at level.

To clean the radiator use compressed air. Keep a maximum of 3.5 bar in order not to

damage the radiator.

To refill the compressor, do not exceed0.7 Kg. for big compressors and 0.5 for small

compressors and do not put the system under excessive pressure.

For further instructions please refer to the instruction manual of the air conditioning system.

Please do not hesitate to contact us for any question!