AlbaCombi - Analog to NMEA 2000 Converter page 2/33

Table of Contents

PRODUCT OVERVIEW .............................................................................................................................. 4

INSTALLATION ......................................................................................................................................... 5

1.1 Selecting a Mounting Location...................................................................................................... 5

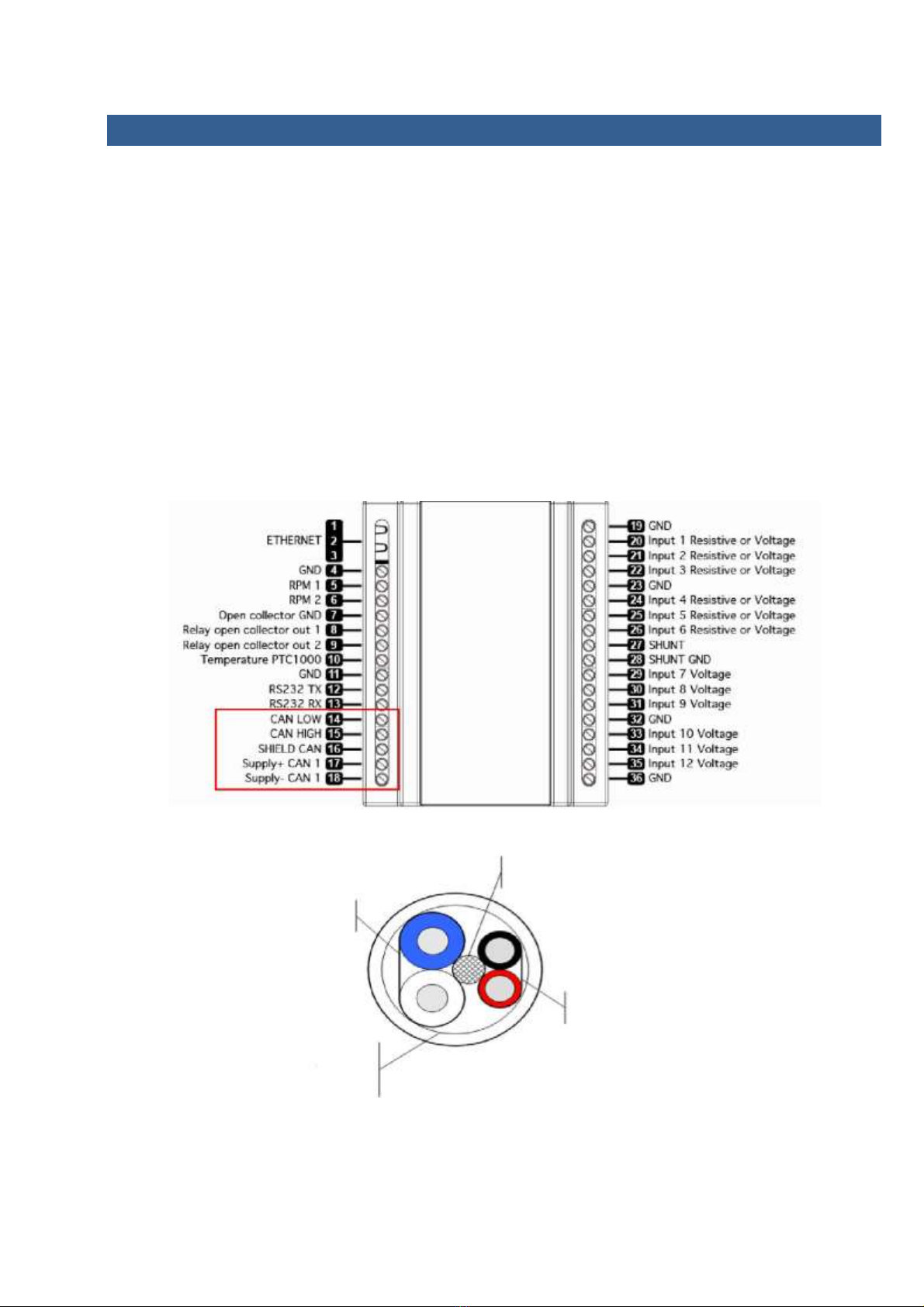

1.2 CAN connection............................................................................................................................. 5

2. MOUNTING THE ALBACOMBI UNIT..................................................................................................... 6

2.1 DIN Rail Mounting ......................................................................................................................... 6

2.2 Connecting to a NMEA 2000 Network .......................................................................................... 6

2.2.1 NMEA 2000 Networks ............................................................................................................ 7

2.2.2 NMEA 2000 Minimum Network Requirements ..................................................................... 7

3. TACHO INPUT CONNECTIONS ............................................................................................................. 8

4. CONFIGURING THE ALBACOMBI DEVICE............................................................................................. 9

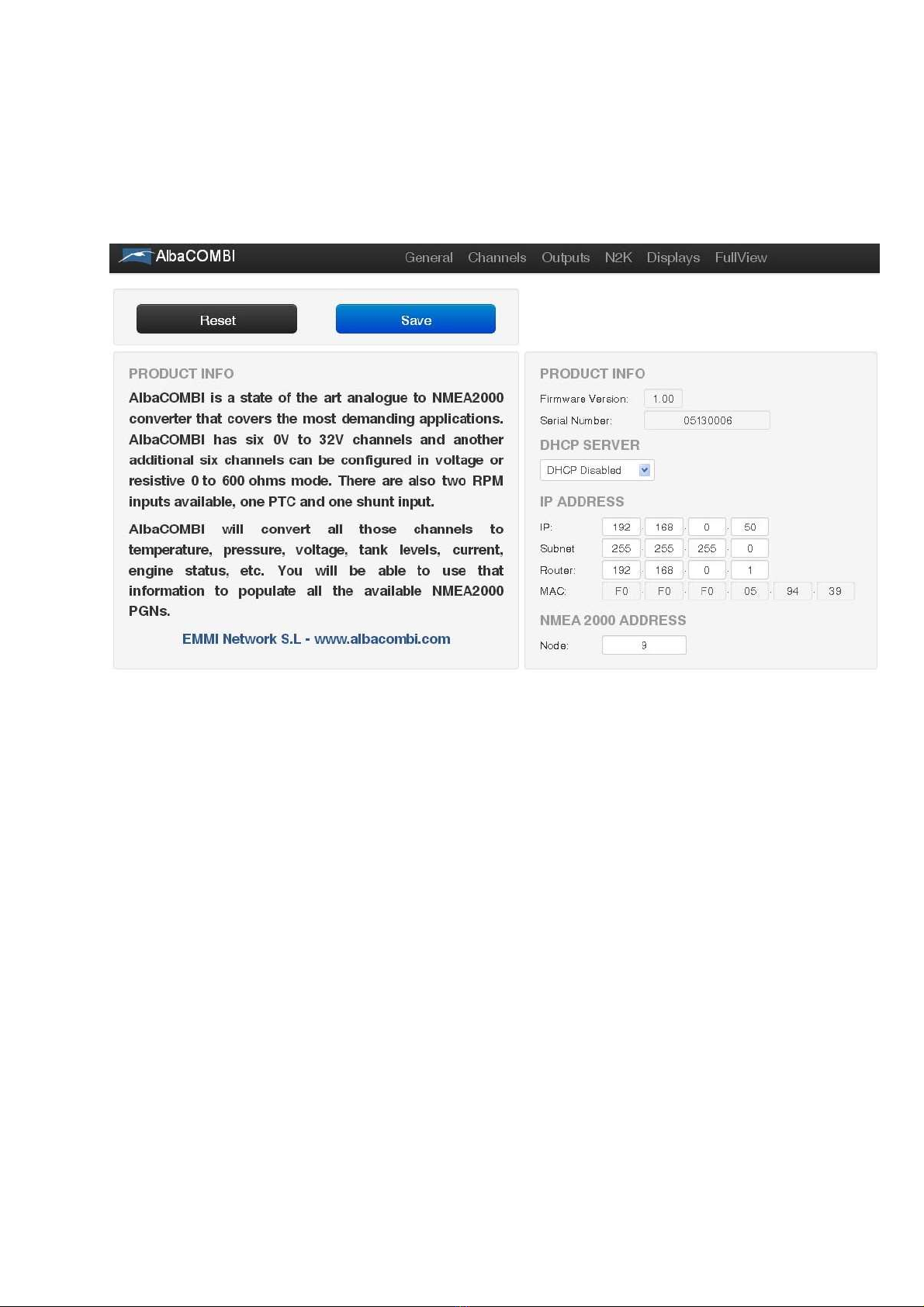

4.1 General Option............................................................................................................................ 10

4.2 Channel Options.......................................................................................................................... 11

4.2.1 RPM Channel........................................................................................................................ 12

4.2.2 PTC1000 Option.................................................................................................................... 14

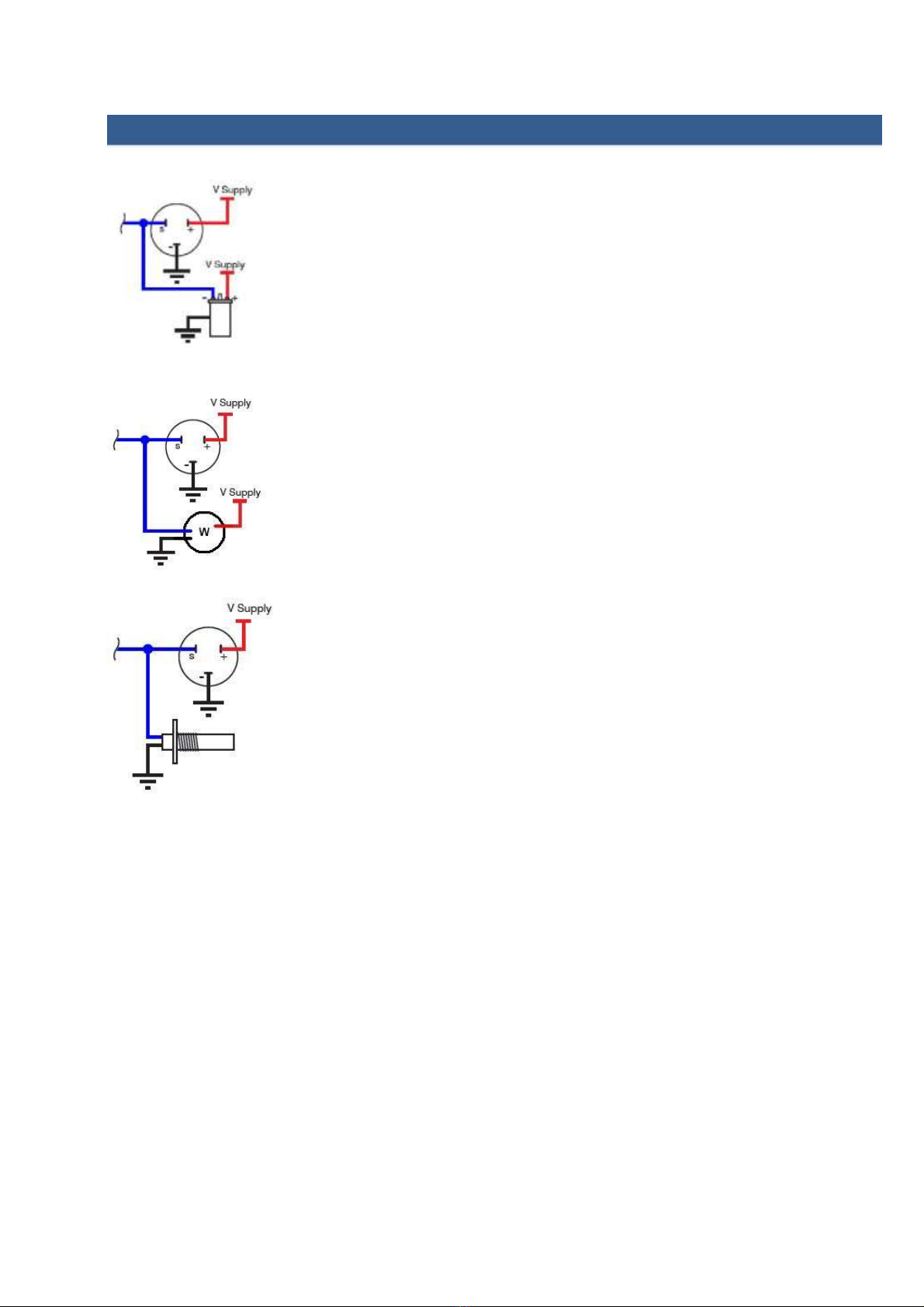

4.2.3 Volt/Resistive Input.............................................................................................................. 16

4.2.4 Shunt Input........................................................................................................................... 18

4.2.5 Voltage Input........................................................................................................................ 19

4.3 Output Option ............................................................................................................................. 21

4.4 NMEA 2000 Option...................................................................................................................... 22

4.4.1 PGN 127488: Engine Rapid Update...................................................................................... 22

4.4.2 PGN 127489: Engine Parameters Dynamic .......................................................................... 23

4.4.3 PGN 127508: Battery Status................................................................................................. 24

4.4.4 PGN 127505: Fluid Level....................................................................................................... 25

4.4.5 PGN 130312: Temperature .................................................................................................. 26

4.4.6 PGN 130314: Pressure.......................................................................................................... 27

4.7 Displays Option............................................................................................................................ 28

4.8 FULL‐SCREEN OPTION.................................................................................................................. 30

5. SPECIFICATIONS................................................................................................................................. 33