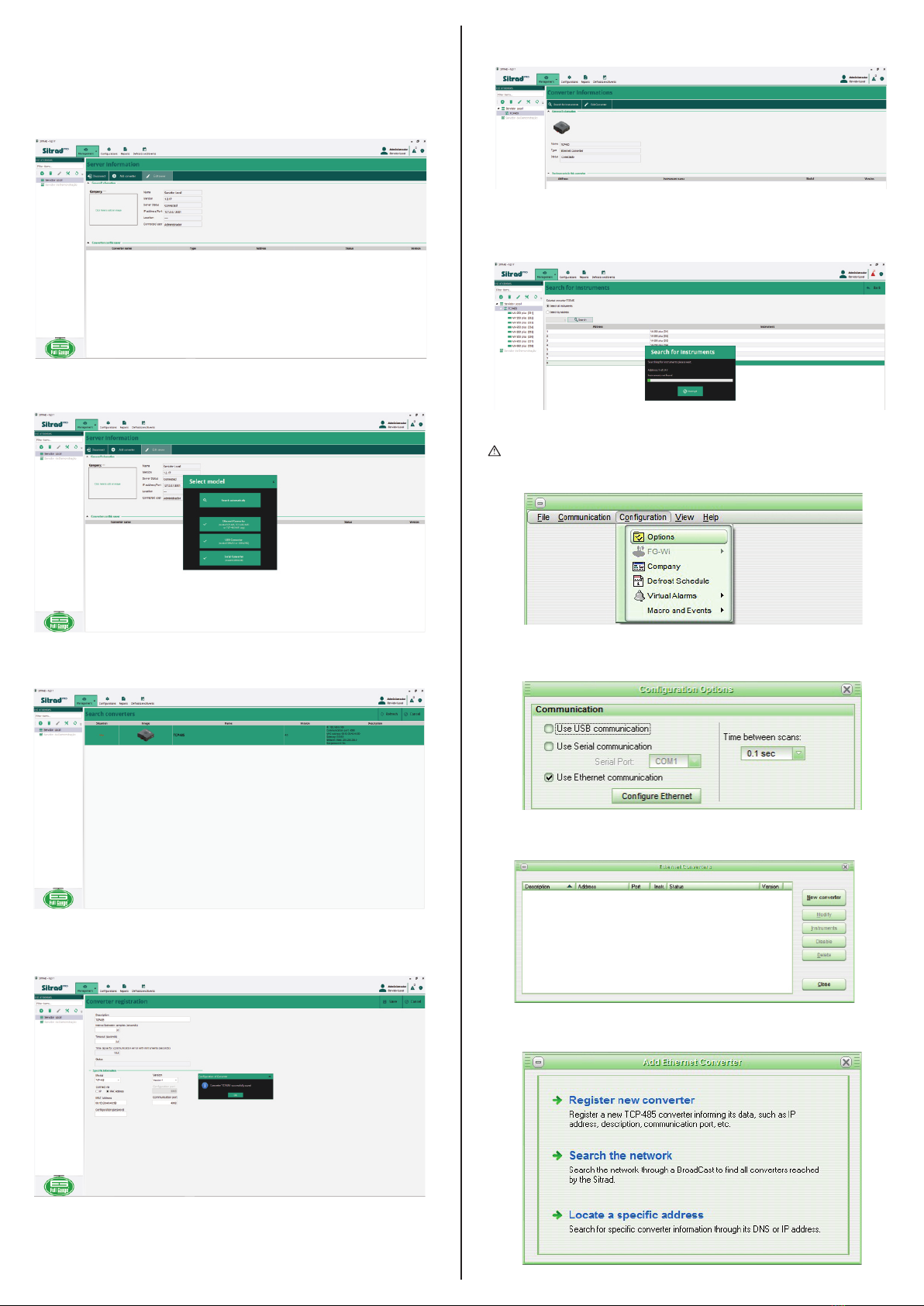

SERIAL CONVERTER / ETHERNET

TCP-485

Ver.04

WARNING

THROUGH CONTINUOUS DEVELOPMENT, FULL GAUGE CONTROLS RESERVES THE RIGHT TO

CHANGE THE INFORMATION IN THIS MANUAL AT ANY TIME, WITHOUT PRIOR NOTICE.

Operating temperature 0 to 50ºC / 32 to 122ºF

Operating humidity 10 to 90% UR (without condensation)

32

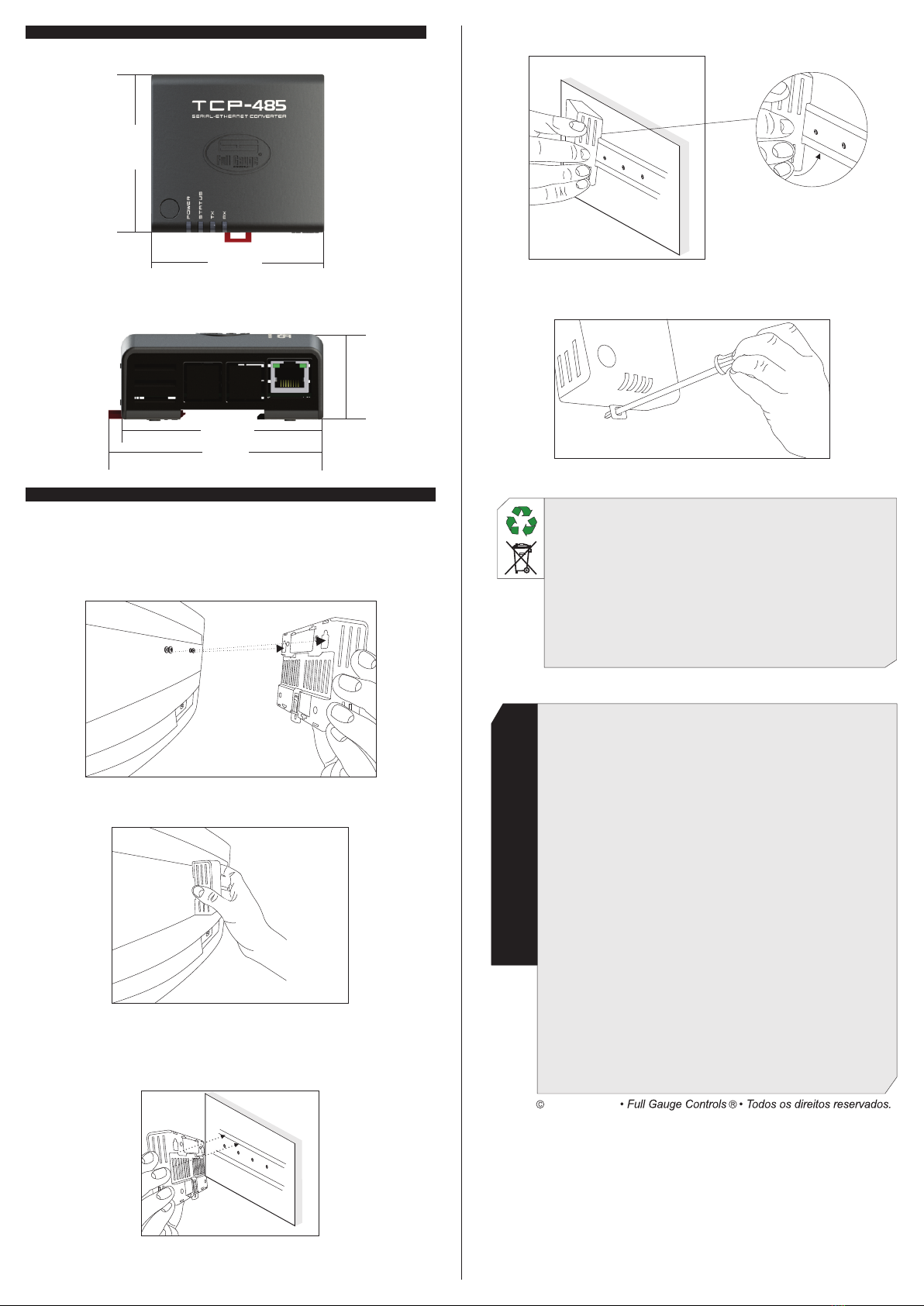

5. INSTALLATION AND OPERATION (DHCP MODE - DEFAULT

CONFIGURATION)

Have this manual in your hands

using the FG Finder application.

Converter power External power supply 5.1 Vdc / 2A

Number of instruments supported per

converter in the RS-485 network

Ethernet speed 10Mbps

Product dimensions 91,0 x 91,1 x 37,1 mm (WxHxP)

Connections

Power supply provided with the converter Input - 100-240Vac (50/60Hz)

Output -5.1Vdc / 2A

1. DESCRIPTION

2. APPLICATIONS

3. TECHNICAL SPECIFICATIONS

The Serial/ Ethernet converter TCP-485 allows interconnecting Full Gauge controllers with the

supervisory software Sitrad through an Ethernet data network using the TCP/IP communication standard.

Currently, many companies have the Ethernet cabling ready in their facilities. With the TCP-485

converter, you can use the cabling already installed, making it unnecessary to create a new cabling for the

RS-485 network of the controllers.

The system consists of an Ethernet/RS-485 converter connected to the Ethernet network (be it by internet,

intranet, or directly to the computer) and Sitrad, which makes a direct TCP/IP connection to the Ethernet/

RS-485 converter, allowing communication with the controllers connected to it.

The converter transforms the RS-485 electrical standard used by the controllers into the TCP/IP

communications protocol used in the interconnection of computer networks.

- Facilities without conditions to install new cabling, and with an Ethernet structure already in place.

- Centralize data collection from multiple remote locations onto one server without needing a computer

dedicated to each remote location.

NOTE: The TCP-485 converter is designed to work specifically with Full Gauge Controls instruments.

Connect interface terminals A,B and with the respective A,B and terminals on connecting blocks and

instruments;

With the TCP-485 powered on, use an Ethernet cable to connect it to a router (switch) in the RJ-45

connectors according to the picture.

-Connection type RJ-45 for connections to a PC using

the twisted-pair cable supplied along with the converter;

- One insulated RS-485 port to connect up to 32

instruments without the need of termination;

- Direct 80 cm Ethernet cable ( no crossover) supplied

along with the converted.

4. WIRING DIAGRAM

LED Power - Power

indication LED

R S - 4 8 5 n e t w o r k

transmission indication LED

R S - 4 8 5 n e t w o r k

reception indication LED

IMPORTANT INFORMATION:

If the ‘’LAN’’ LED indicator in the RJ-45 connector does not light up upon connecting

the TCP-485 converter directly to the network adapter of the computer, you may

possibly need to use a crossover cable ( not supplied by Full Gauge) or connect the

computer and the converter via a HUB or a Switch.

STANDARD OPERATING MODE:

The factory’s default operation of TCP-485 is DHCP Mode. See item 7 - Restoring the

default settings of the converter/ Changing IP Mode to switch the operation Mode.

IMPORTANT:

For a correct and robust installation of the RS-485 network, see item 9 -

Interconnecting the controllers and TCP-485.

!

!

!

Supervisory

system

Serial Ethernet

communication

RS

485

L E D S t a t u s -

Connect ion sta tus

indication LED

Reset key

Converter power

TCP-485

RJ45 Router

Controller

Source

RS-485

MT-530 super

TCP485V04-02T-16955

Communication network

with RS-485 instruments

MT-530 super

BEFORE THE INSTALLATION OF THE CONVERTER, WE RECOMMEND READING THE

INSTRUCTION MANUAL IN FULL TO PREVENT POSSIBLE DAMAGE TO THE PRODUCT.

PRODUCT INSTALLATION PRECAUTIONS:

Before performing any procedure on this instrument, disconnect it from the power grid;

Ensure that it has adequate ventilation, avoiding installation on control panels containing devices that

could cause it to operate outside its specified temperature range;

Install the product away from sources that may generate eletromagnetic disturbances, such as :

motors, contactors, relays, electrovalves, etc.;

AUTHORIZED SERVICES:

The installation and maintenance of the product must be performed only by qualified personnel;

ACCESSORIES

Use only Full Gauge Controls original accessories.

If you have any questions, please contact our technical support