Precautions

Four

5

to

21

m3

/h

pump

models

with

the

following main characteristics:

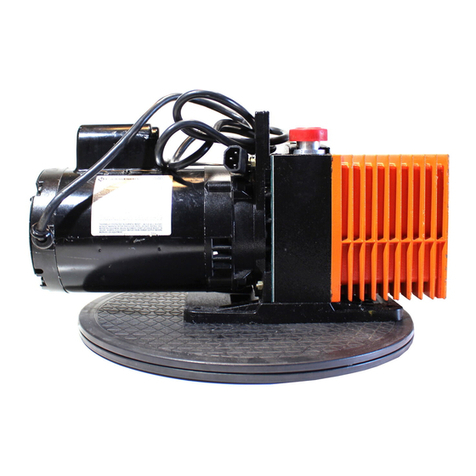

- A

direct

drive

motor,

making

them

very compact.

-An electrically insulated fold-away

handle

is

used for easy carrying.

-An

anti-suckback

system

ensures

the tightness of the pump during

accidental or voluntary shutdowns.

- A

gas

ballast

enables the pumping

of condensable vapours (except for

C2

series).

-

The

universal three-phase or single-

phase

motor

can be disassembled

independently

of the

rest

of the

pump, without the need to drain

the

oil case.

-

On

the oil case, a

vertical

sight

glass

can be

used

to

inspect

the

oil

level easily when filling

the

tank and

during the operation of

the

pump.

- A

neutral

gas

purge

is

used

to

degas oil and dilute pumped gases

on

C2

series models.

5

to

21

m3

/h

rotary

vane

pumps.

I,

SO,

C1,

C2

Pascal

series

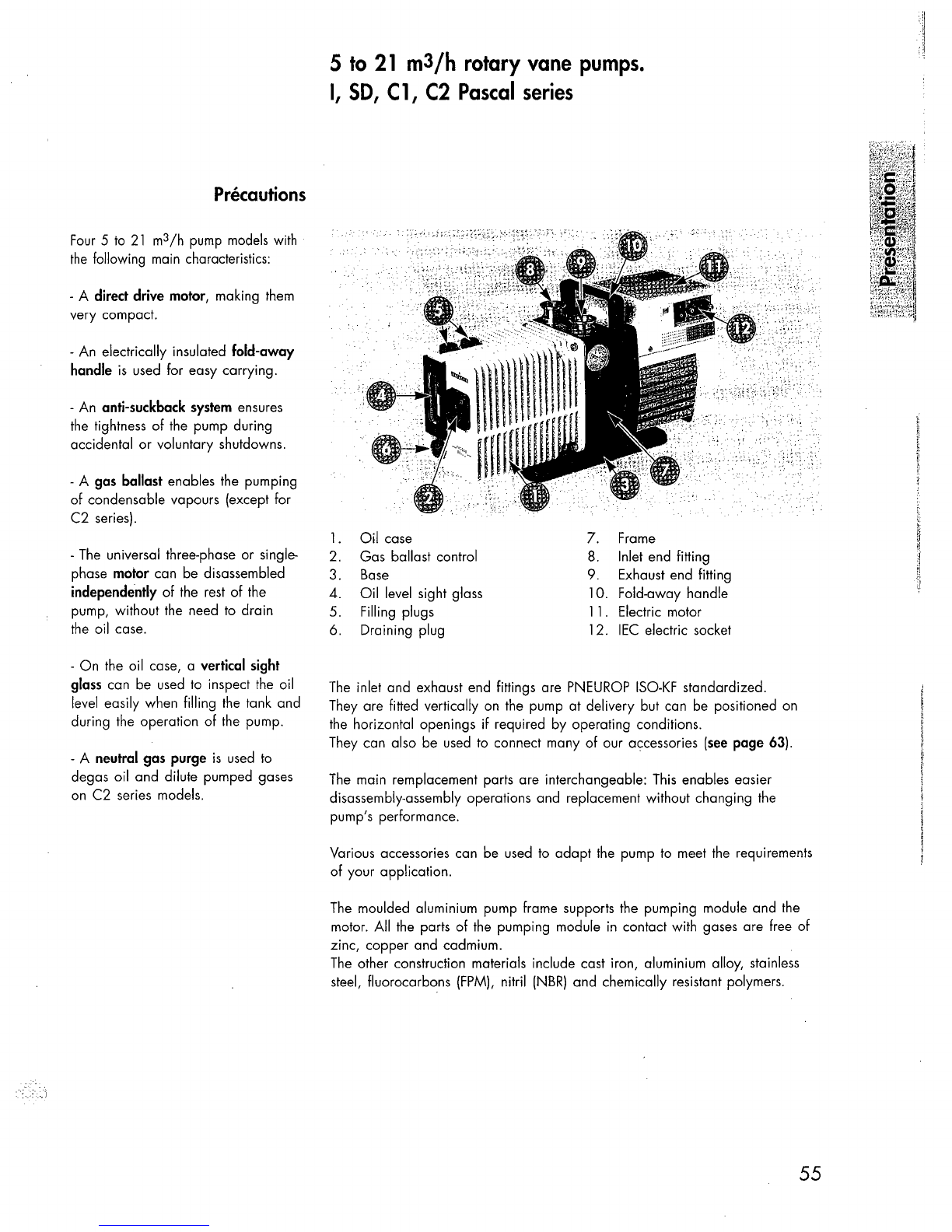

1.

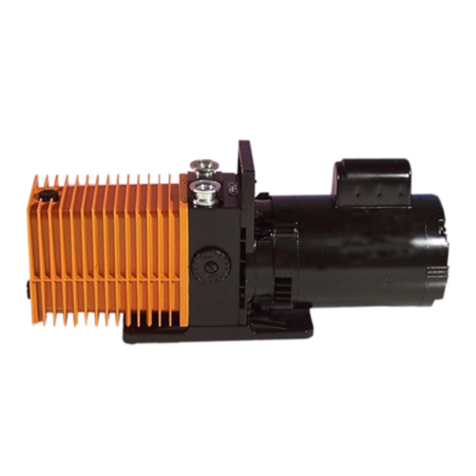

Oil

case

7.

Frame

2. Gas ballast control

8.

Inlet end fitting

3.

Base

9.

Exhaust end fitting

4.

Oil

level sight glass 10. Fold-away handle

5.

Filling plugs 11. Electric motor

6. Draining plug 12.

IEC

electric socket

The

inlet and exhaust end fittings are

PNEUROP

ISO-KF

standardized.

They are fitted vertically on the pump at delivery but can be positioned on

the horizontal openings

if

required

by

operating conditions.

They can also be

used

to connect many of our accessories

(see

page

63).

The

main remplacement parts are interchangeable:

This

enables easier

disassembly-assembly operations and replacement without changing the

pump's performance.

Various accessories can be

used

to

adapt

the

pump to meet the requirements

of your application.

The

moulded aluminium pump frame supports the pumping module and

the

motor. All the parts of the pumping module

in

contact with gases are free of

zinc, copper and cadmium.

The

other construction materials include cast iron, aluminium alloy, stainless

steel, fluorocarbons

(FPM),

nitril

(NBR)

and chemically resistant polymers.

55

"'1

]

'I