CYLINDER SETUP

1. Examine the canister and valve for any damage, and check the expiration date on the label.

Observe all cautions and safety warnings found on the canister.

2. Remove the protective cap and screw the regulator valve to the canister. Attach the rigid

delivery tube. Never modify the delivery tube in any way.

CAUTION! Damaged or broken valves can turn a canister into an unguided missile.

Attach the valve in a safe location.

CALIBRATING A HANDSET

1. Power the handset on by holding down either the right or left button.

2. Access the Menu by pressing and holding the left button. Scroll through the menu and select

System Maintenance. The four digit code which is provided with the V3 accesses this

menu.

3. Enter the code and move the cursor to OK?whennished.PushtherightbuttontoSelect.

This enters the Service menu.

4. Scroll through the Service menu and press select Calibration.

5. The current handset Date/Time is displayed. To proceed select OK with the right button. This

enters the Select Type menu.

NOTE! If a tachograph is installed the date/time cannot be changed.

6. The Select type menu contains the calibration options. Scroll to Dry Gas and push the right

button to Select. This enters the Select value menu.

7. The Select value menu contains the gas standard concentration options. Verify that 130PPM

is on the canister label, and use the left button to scroll to 130PPM. Push the right button to

Select. This enters the Altitude menu.

8. The Altitude menu contains the altitude correction factor. Verify the altitude value using the

altitude reference guide, which is on the last page of this guide. The left button increases in

increments of 200 meters. Press the right button to Accept.

9. A Wait message is displayed followed by a 2:00 minute warm-up. The handset is ready for

calibration when the Turn on gas message is displayed.

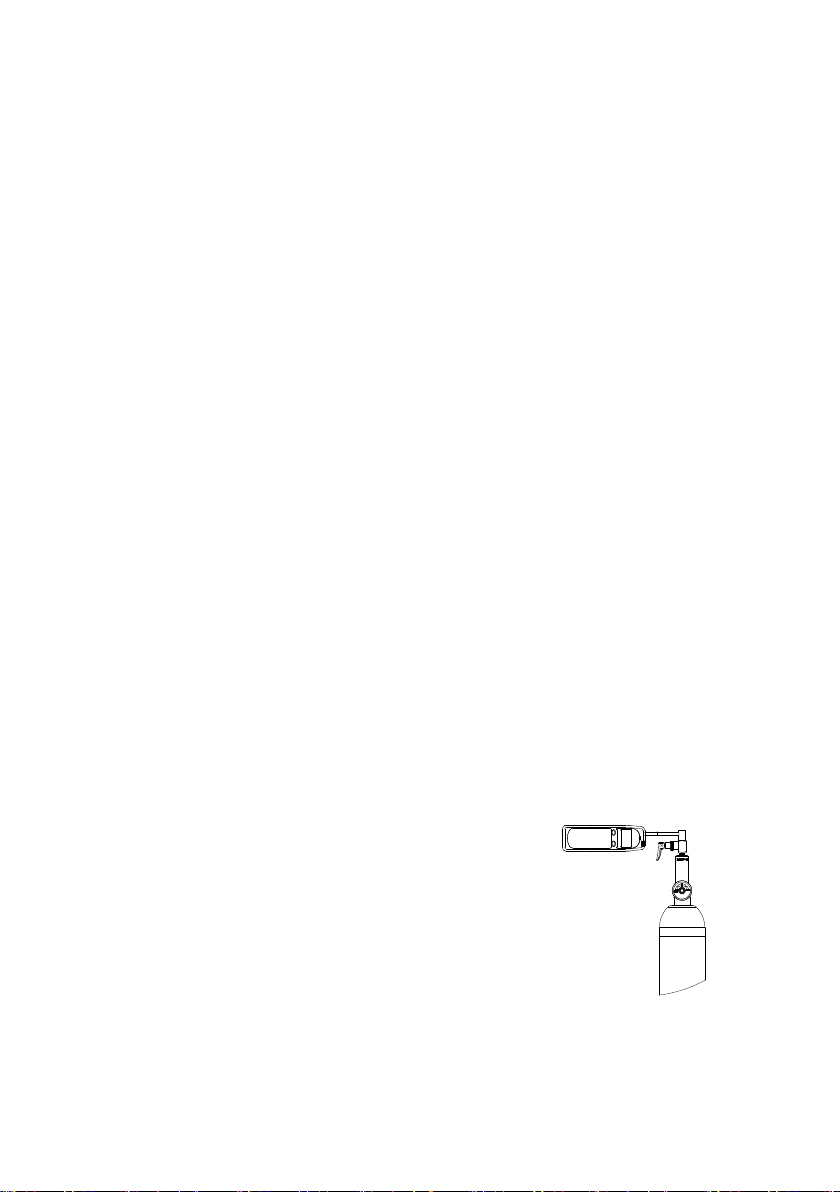

10.Insert the delivery tube from the regulator valve into the mouthpiece port. Keep hold of the

handset as the delivery tube is rigid.

11. Press the valve down to release the gas while keeping

holdofthehandset(seegure).Thehandsetanalyzes

the gas standard and displays a Blowing… message

followed by Analyzing message.

Continue holding the valve down until the handset clicks

and then beeps, indicating that the test is complete.

12.Thehandsetanalyzesthetest,whichis

followed by a Wait message and 0:45 second

countdown. The handset is ready for the second sample

when the Turn on Gas message is displayed.