SPECIFICATION

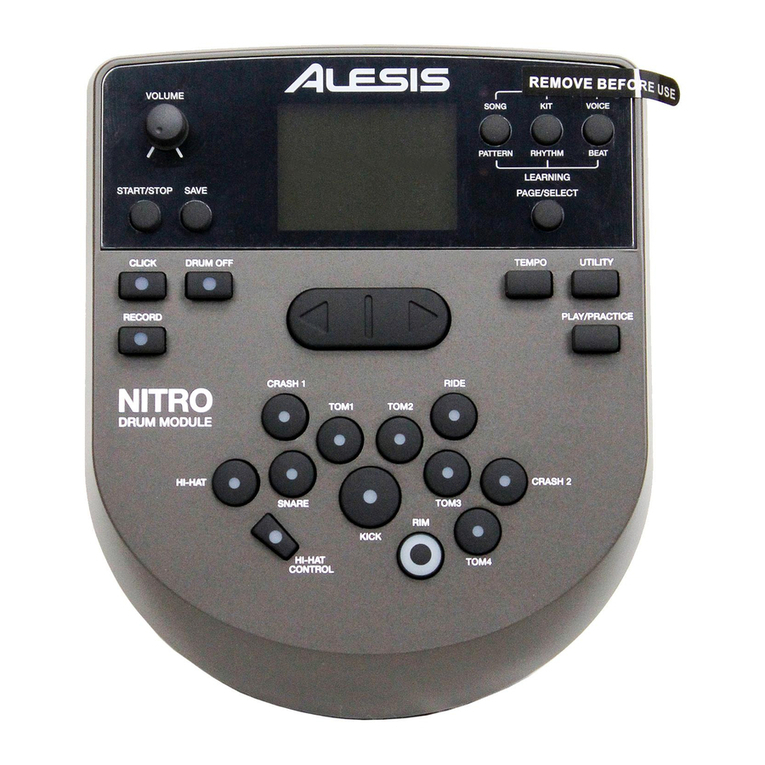

Description of the Controls

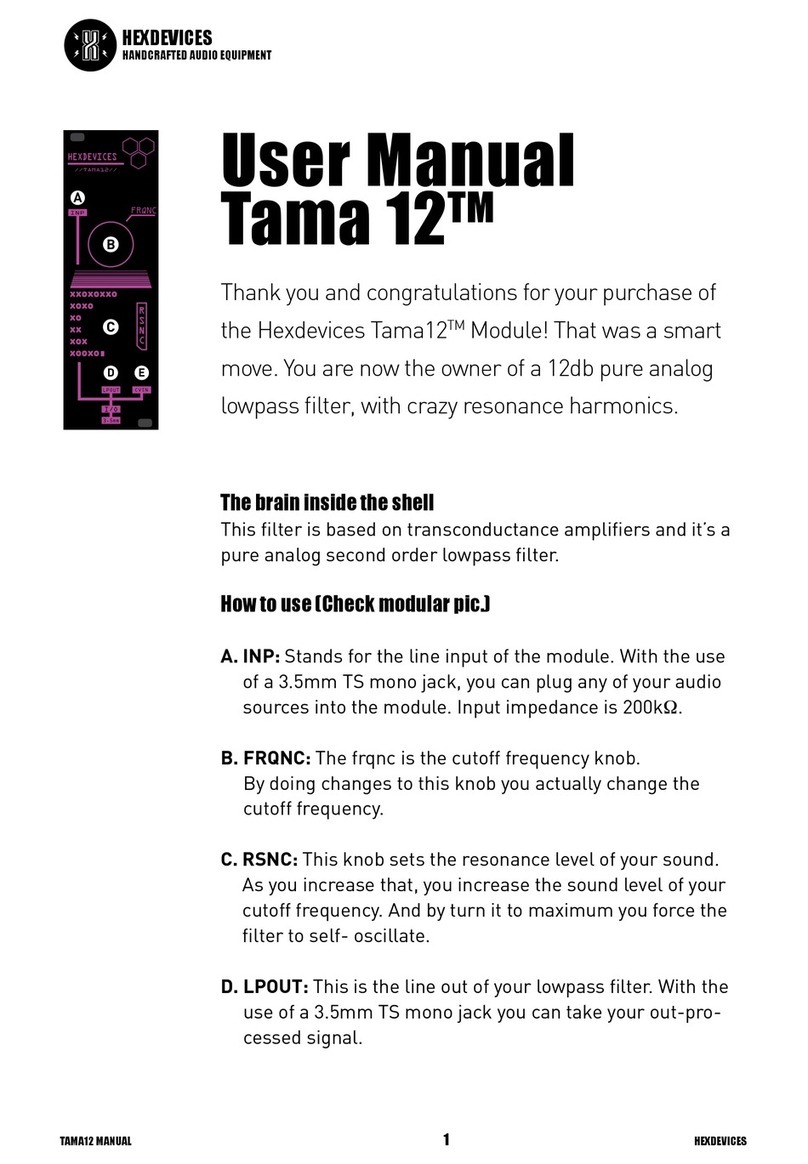

There are twenty-four channel buttons on the DEQ224. These are

the [BAND SELECT] buttons. Above each button is a number

like “25” or “19k.”These stand for the audio frequencies,

measured in Hertz (Hz), which are selected for editing by pressing

the [BAND SELECT] buttons below them.

Situated just right of the [BAND SELECT] buttons you will find

three larger buttons. The one in the very middle is the [POWER]

button. On either side of that are the [DOWN] and [UP]

buttons, which are used to edit the gain amount of the frequency

you have selected with the [BAND SELECT] buttons. (It is also

possible to select and edit several frequencies at once; more about

this later.) The [DOWN/UP] buttons are also used to select

programs in Program mode.

Directly above these three buttons are three more buttons: the

[BYPASS],[STORE],and [CHANNEL/EXIT] buttons. Their

functions are as follows:

[BYPASS]

When this button is first pressed, a red LED will light. This means

the DEQ224 is in Bypass mode. As long as this LED is lit,

incoming audio will pass through the unit without being affected

by the DEQ224. This is useful for comparing the “equalized”

signal with the original signal so you can decide if you like the edit

you made. Press the button again to get out of Bypass mode and

hear the effect.

[STORE]

Once you have made an edit you would like to keep, press this

button to enter Store mode. From there you can decide which

of the 30 User locations will become the new home for the

edited Program. You can also copy the settings from Channel A

to Channel Bas you store a program. For more information on

this function, see page 36.

[CHANNEL/EXIT]

This button serves a dual purpose:

1. While in Program mode, pressing this button will cycle the

DEQ224 through 3 modes. You can select Channel A,

Channel B or you can Link A and B together which will cause

the settings for Channel B to “mirror”the settings for Channel

A. This is useful for quickly setting up a program without

having to make independent adjustments for each channel.

2. If you’re in the middle of some other activity, such as editing

or storing, pressing this button will allow you to “exit”to

Program mode.

Audio Input

Input Connectors: 2 Impedance-Balanced 1/4”TRS

jacks

Nominal Input Level: -10dBV (-15dBFS)

Maximum Input Level: +5dBV (1.78 Vrms)

Input Impedance: 10kO

Audio Output

Output Connectors: 2 Impedance-Balanced 1/4”TRS

jacks

Nominal Output Level: -10dBV (-15dBFS)

Maximum Output Level: +5dBV (1.78 Vrms)

Output Impedance: 220O

MODEL:DEQ224