To control the dispenser, Alfa makes the web-based

interface called AlfaTint available to all its customers.

In case you wish to apply your own software, Alfa provides

a series of calls (API Rest) allowing interfacing the

machine with any third-party software.

For more details on the API Rest, please refer to the

technical manual or contact Alfa Service Department.

In the following, we will refer to AlfaTint interface

commands.

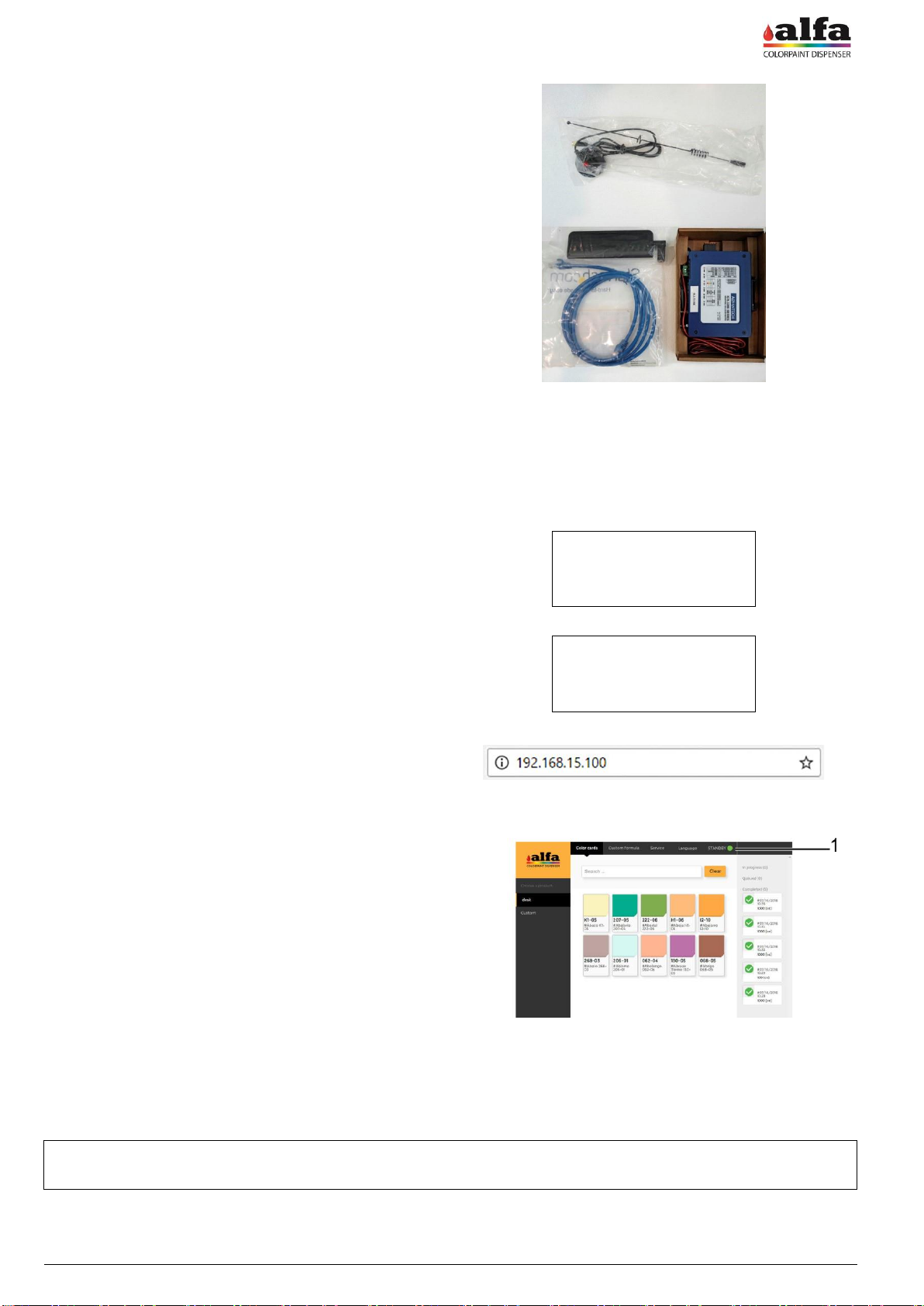

LTE modems supplied by Alfa are always configured to

provide router-machine communication at the address

192.168.0.100.

In case the router is used, it will be necessary to start VPN

connection by using the specially provided certificate and

to connect to the router IP by setting the last digits of the IP

address to 100 (see technical manual for more detailed

information).

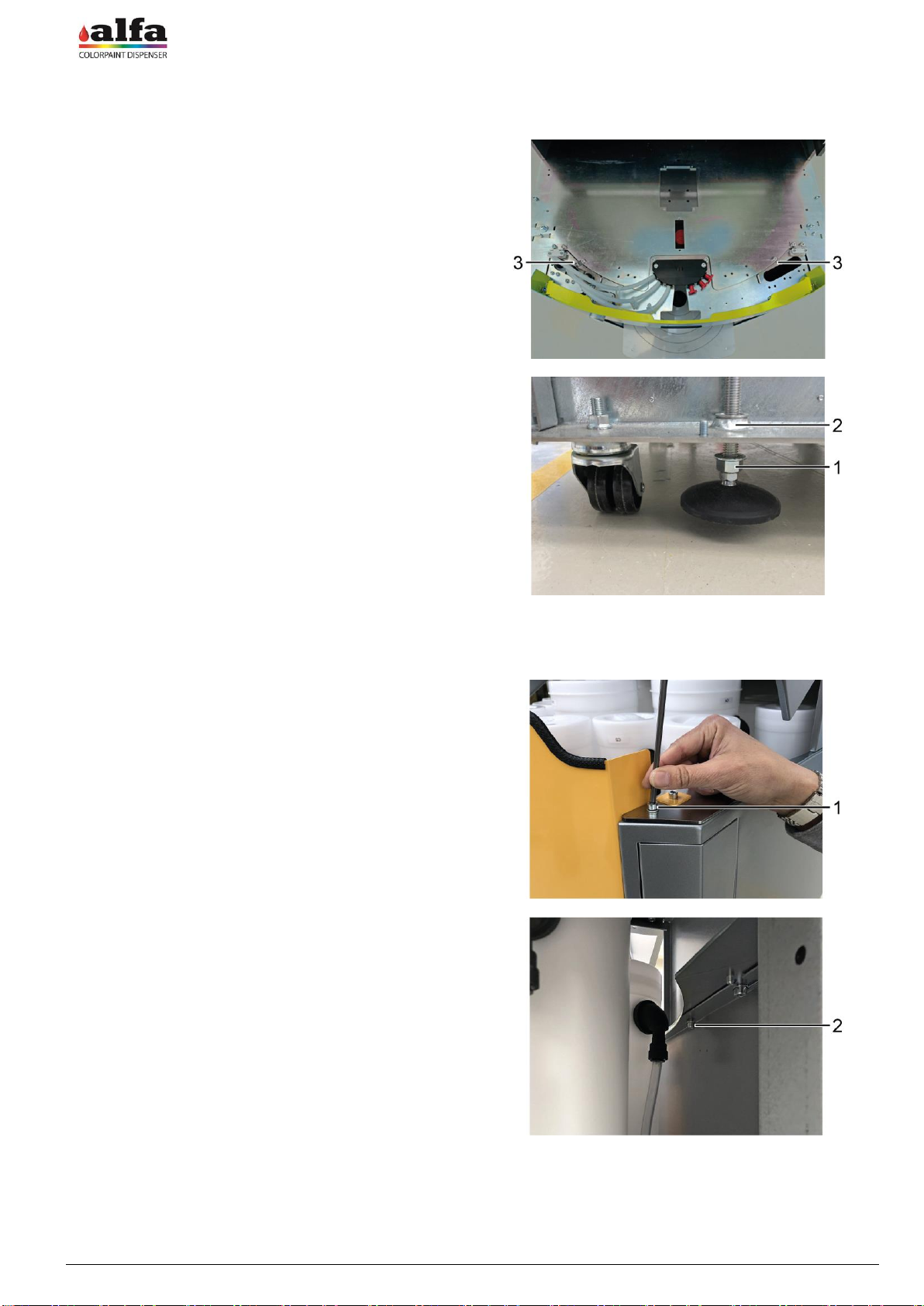

Different LTE Routers may be supplied, depending of the

destination market of the machine.

With reference to the figure on the side, the upper model

(1) is suitable for North American markets (Mexico, USA,

Canada), whereas the lower model (2) can be used

elsewhere in the world. Further models can be used in

specific areas where special type-approval requirements

are necessary (e.g. Australia).

- Connect the machine Ethernet 0.100 plug to one of the

two Router Ethernet sockets and the PC Ethernet plug

to the other Router Ethernet socket;

- Connect the power cable present inside the router box

between modem PWR connector and 24Vdc socket

available in the internal power supply unit. As an

alternative, it is possible to use the power supply unit

included in the package, to be directly connected to an

external mains socket.

- Screw the antenna supplied (3) to ANT threaded

connector;

- Insert a data SIM into SIM1 slot, taking care to

previously check that no PIN is enabled (before

inserting the SIM into the router, insert the SIM into a

telephone and disable the PIN if necessary).

NOTE: In some types of modem, SIM1 slot can be

located in the rear part of the modem.